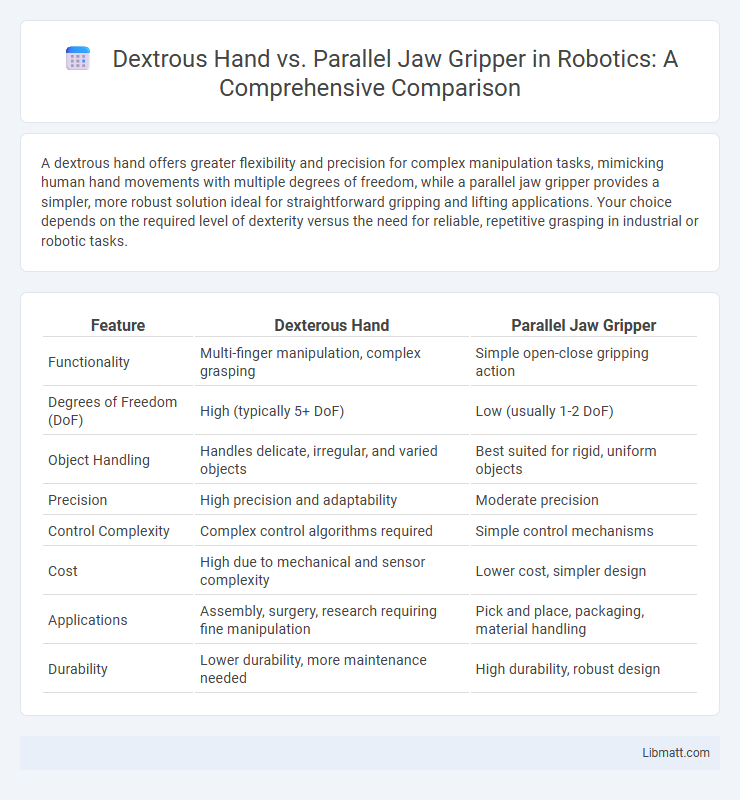

A dextrous hand offers greater flexibility and precision for complex manipulation tasks, mimicking human hand movements with multiple degrees of freedom, while a parallel jaw gripper provides a simpler, more robust solution ideal for straightforward gripping and lifting applications. Your choice depends on the required level of dexterity versus the need for reliable, repetitive grasping in industrial or robotic tasks.

Table of Comparison

| Feature | Dexterous Hand | Parallel Jaw Gripper |

|---|---|---|

| Functionality | Multi-finger manipulation, complex grasping | Simple open-close gripping action |

| Degrees of Freedom (DoF) | High (typically 5+ DoF) | Low (usually 1-2 DoF) |

| Object Handling | Handles delicate, irregular, and varied objects | Best suited for rigid, uniform objects |

| Precision | High precision and adaptability | Moderate precision |

| Control Complexity | Complex control algorithms required | Simple control mechanisms |

| Cost | High due to mechanical and sensor complexity | Lower cost, simpler design |

| Applications | Assembly, surgery, research requiring fine manipulation | Pick and place, packaging, material handling |

| Durability | Lower durability, more maintenance needed | High durability, robust design |

Introduction to Robotic Grippers

Robotic grippers include dextrous hands and parallel jaw grippers, each designed for specific manipulation tasks. Dextrous hands replicate human finger movements, providing high flexibility and precision for handling complex objects. Parallel jaw grippers feature two opposing fingers that move in parallel lines, offering straightforward, robust gripping ideal for simple, repetitive tasks in industrial automation.

Overview of Dextrous Hands

Dextrous hands feature multiple articulated fingers and advanced sensor integration, enabling precise manipulation of complex objects and mimicking human hand movements with high dexterity. Compared to parallel jaw grippers, which typically use two rigid fingers for simple, linear grasping, dextrous hands provide enhanced adaptability in handling irregular shapes and delicate tasks. Your robotic applications demanding fine motor skills and versatile object interaction benefit significantly from the sophisticated control and flexibility of dextrous hands.

Understanding Parallel Jaw Grippers

Parallel jaw grippers feature two opposing fingers that move linearly to grasp objects, offering precise control and strong gripping force ideal for handling rigid and uniform items. Their simple mechanical design ensures high reliability and ease of maintenance, making them widely used in industrial automation for pick-and-place tasks. Compared to dextrous hands, parallel jaw grippers excel in speed and repeatability but lack the complex manipulation and adaptability required for handling diverse shapes and delicate objects.

Key Differences in Design

Dextrous hands feature multiple articulated fingers with independent joint control, enabling complex manipulation and fine motor tasks, whereas parallel jaw grippers consist of two rigid opposing jaws designed for simple grasping and holding actions. The design complexity of dextrous hands supports adaptive and precise interactions with a wide variety of object shapes, while parallel jaw grippers prioritize robustness and speed for repetitive pick-and-place operations. Mechanically, dextrous hands require advanced sensing and control systems to coordinate finger movements, contrasting with the simpler actuation mechanisms of parallel jaw grippers.

Range of Motion and Flexibility

Dextrous hands offer a superior range of motion and flexibility due to their multi-fingered design, allowing precise manipulation of complex objects and fine motor tasks. Parallel jaw grippers provide limited degrees of freedom, typically two opposing fingers, restricting their capability to grasp irregularly shaped items or perform intricate movements. The enhanced articulation in dextrous hands supports adaptive grip patterns, making them ideal for applications requiring versatility and delicate handling.

Gripping Efficiency and Precision

Dextrous hands offer superior gripping efficiency and precision due to their multi-fingered design, allowing adaptive and delicate manipulation of complex shapes and varied textures. Parallel jaw grippers provide consistent force and rapid grasping on uniform objects, excelling in tasks requiring straightforward, repetitive gripping motions. The choice between the two depends on application requirements, where high precision and adaptability favor dextrous hands while speed and simplicity suit parallel jaw grippers.

Application Suitability and Use Cases

Dextrous hands excel in complex manipulation tasks requiring fine motor skills, such as assembly, delicate object handling, and robotics-assisted surgery, due to their multi-fingered, articulated structures that mimic human hand movements. Parallel jaw grippers are ideal for industrial applications involving repetitive grasping of uniform objects, like palletizing, pick-and-place operations, and packaging, because of their simple design and strong, consistent gripping force. The choice between the two depends on the precision and adaptability needed, with dextrous hands suited for nuanced dexterity and parallel jaw grippers optimized for speed and robustness in standardized environments.

Cost and Maintenance Considerations

Dextrous hands typically incur higher costs due to their complex design, advanced sensors, and multiple actuators, resulting in significant maintenance demands and potential downtime. Parallel jaw grippers offer a cost-effective alternative with simpler mechanics, lower initial investment, and easier maintenance procedures. Industries often choose parallel jaw grippers for high-volume, repetitive tasks to minimize total ownership cost while reserving dextrous hands for precision manipulation requiring finer control.

Technological Advancements and Trends

Dextrous hands incorporate advanced sensor arrays and multi-degree-of-freedom actuators, enabling complex manipulation and adaptive grasping in unstructured environments. Parallel jaw grippers have evolved with improved force control, lightweight materials, and modular designs, enhancing efficiency in repetitive industrial tasks. Current trends emphasize integrating AI-driven feedback systems and soft robotics in both gripper types to boost precision and versatility.

Choosing the Right Gripper for Your Needs

Choosing the right gripper depends on the complexity of the task and the precision required; a dextrous hand offers multiple degrees of freedom for intricate manipulations, making it ideal for handling irregular objects or delicate assemblies. Parallel jaw grippers, with their simpler design and reliable linear motion, excel at gripping objects with consistent shapes, providing strong holding force and ease of use in industrial automation. Assess your application's requirements for flexibility and control to determine whether the advanced capabilities of a dextrous hand or the straightforward efficiency of a parallel jaw gripper best suit your needs.

Dextrous hand vs Parallel jaw gripper Infographic

libmatt.com

libmatt.com