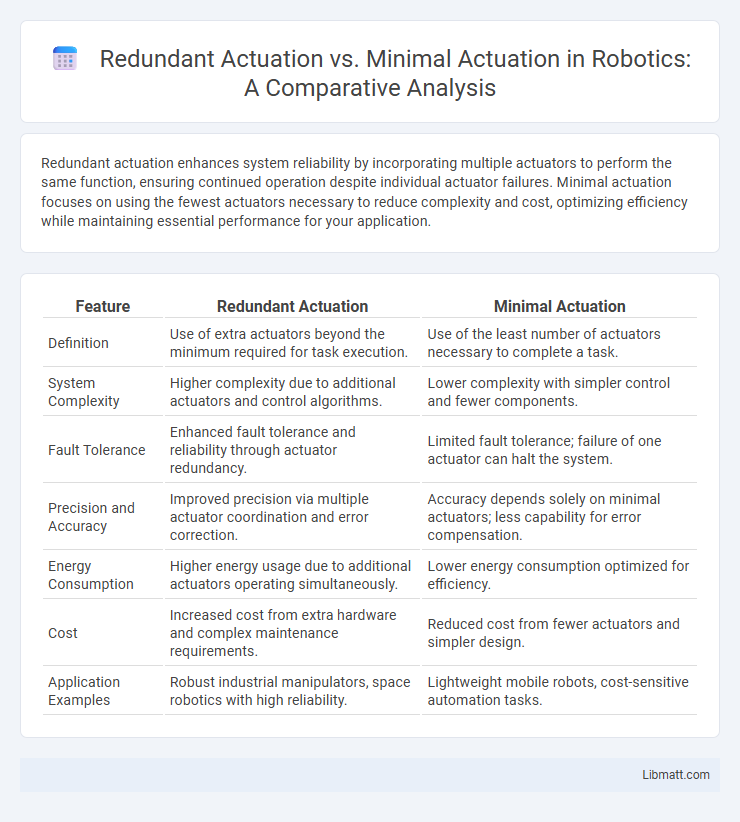

Redundant actuation enhances system reliability by incorporating multiple actuators to perform the same function, ensuring continued operation despite individual actuator failures. Minimal actuation focuses on using the fewest actuators necessary to reduce complexity and cost, optimizing efficiency while maintaining essential performance for your application.

Table of Comparison

| Feature | Redundant Actuation | Minimal Actuation |

|---|---|---|

| Definition | Use of extra actuators beyond the minimum required for task execution. | Use of the least number of actuators necessary to complete a task. |

| System Complexity | Higher complexity due to additional actuators and control algorithms. | Lower complexity with simpler control and fewer components. |

| Fault Tolerance | Enhanced fault tolerance and reliability through actuator redundancy. | Limited fault tolerance; failure of one actuator can halt the system. |

| Precision and Accuracy | Improved precision via multiple actuator coordination and error correction. | Accuracy depends solely on minimal actuators; less capability for error compensation. |

| Energy Consumption | Higher energy usage due to additional actuators operating simultaneously. | Lower energy consumption optimized for efficiency. |

| Cost | Increased cost from extra hardware and complex maintenance requirements. | Reduced cost from fewer actuators and simpler design. |

| Application Examples | Robust industrial manipulators, space robotics with high reliability. | Lightweight mobile robots, cost-sensitive automation tasks. |

Introduction to Actuation in Engineering

Actuation in engineering refers to the mechanism that controls the movement or operation of a system, often converting energy into motion. Redundant actuation involves multiple actuators working together to enhance reliability and fault tolerance, ensuring continuous system performance even if one actuator fails. Minimal actuation focuses on using the fewest number of actuators necessary, optimizing cost, weight, and complexity while maintaining sufficient control for your engineering application.

Understanding Redundant Actuation

Redundant actuation involves using multiple actuators to perform the same function, enhancing system reliability and fault tolerance by allowing continuous operation even if one actuator fails. In contrast, minimal actuation relies on the least number of actuators necessary, optimizing cost and weight but reducing redundancy. Understanding redundant actuation helps you design systems with improved safety and flexibility for critical applications like aerospace and robotics.

What is Minimal Actuation?

Minimal actuation refers to a control strategy that uses the least number of actuators required to perform a specific task effectively, reducing complexity and energy consumption. Unlike redundant actuation, which employs multiple actuators to increase reliability and fault tolerance, minimal actuation optimizes system design by focusing on essential functions only. Your system benefits from minimal actuation by achieving efficiency and cost savings without compromising performance.

Key Differences Between Redundant and Minimal Actuation

Redundant actuation involves multiple actuators working simultaneously to enhance system reliability and fault tolerance, ensuring continuous operation even if one actuator fails. Minimal actuation uses the smallest number of actuators necessary to perform a task, prioritizing simplicity, cost efficiency, and weight reduction. Key differences include system complexity, fault tolerance, and energy consumption, with redundant actuation increasing robustness at the expense of complexity and minimal actuation focusing on efficiency and simplicity.

Advantages of Redundant Actuation Systems

Redundant actuation systems enhance reliability by providing backup actuators that prevent system failure during component malfunctions, ensuring continuous operation in critical applications such as aerospace and robotics. These systems improve fault tolerance, enabling real-time error correction and reducing downtime, which is vital for high-stakes environments where safety and performance are paramount. Their ability to distribute loads across multiple actuators also increases system longevity and efficiency by minimizing wear and tear on individual components.

Benefits of Minimal Actuation Approaches

Minimal actuation approaches offer significant benefits including reduced energy consumption and lower system complexity, leading to enhanced efficiency and cost-effectiveness. By utilizing fewer actuators, maintenance requirements decrease and overall reliability improves due to fewer failure points. These streamlined systems also enable faster response times and simplified control algorithms, optimizing performance in various applications such as robotics and aerospace.

Use Cases: When to Choose Redundant vs Minimal Actuation

Redundant actuation is ideal in safety-critical applications such as aerospace, medical devices, and autonomous vehicles where system failure is not an option, providing backup mechanisms to ensure continuous operation. Minimal actuation suits cost-sensitive or space-constrained projects like consumer electronics or small robotics, where simplicity and efficiency are prioritized over fault tolerance. Your choice depends on the application's reliability requirements, budget constraints, and the criticality of uninterrupted performance.

Challenges and Limitations of Each Approach

Redundant actuation presents challenges such as increased system complexity, higher weight, and elevated energy consumption, which can limit efficiency and maintenance. Minimal actuation faces limitations in fault tolerance and robustness, as fewer actuators reduce the system's ability to compensate for failures or adapt to dynamic conditions. Your choice between these approaches depends on balancing reliability needs against constraints like cost, weight, and system resilience.

Cost and Efficiency Considerations

Redundant actuation systems increase reliability and fault tolerance but often result in higher initial costs and more complex maintenance requirements compared to minimal actuation designs. Minimal actuation optimizes cost-efficiency by reducing the number of actuators, leading to lower fuel consumption and simpler control mechanisms, yet it may compromise system redundancy and fail-safe capabilities. In applications where budget constraints and operational efficiency are critical, minimal actuation provides a more cost-effective solution, while industries prioritizing safety and uptime often invest in redundant actuation despite the increased expenses.

Future Trends in Actuation Technology

Future trends in actuation technology emphasize the integration of advanced sensors and AI-driven control algorithms to optimize redundant actuation systems, enhancing reliability and fault tolerance in critical applications like aerospace and robotics. Minimal actuation designs focus on energy efficiency and simplicity, leveraging smart materials such as piezoelectrics and shape-memory alloys to reduce size and power consumption. Emerging research explores hybrid approaches combining redundancy benefits with minimal actuator counts, aiming to balance system robustness with lightweight, cost-effective solutions.

Redundant Actuation vs Minimal Actuation Infographic

libmatt.com

libmatt.com