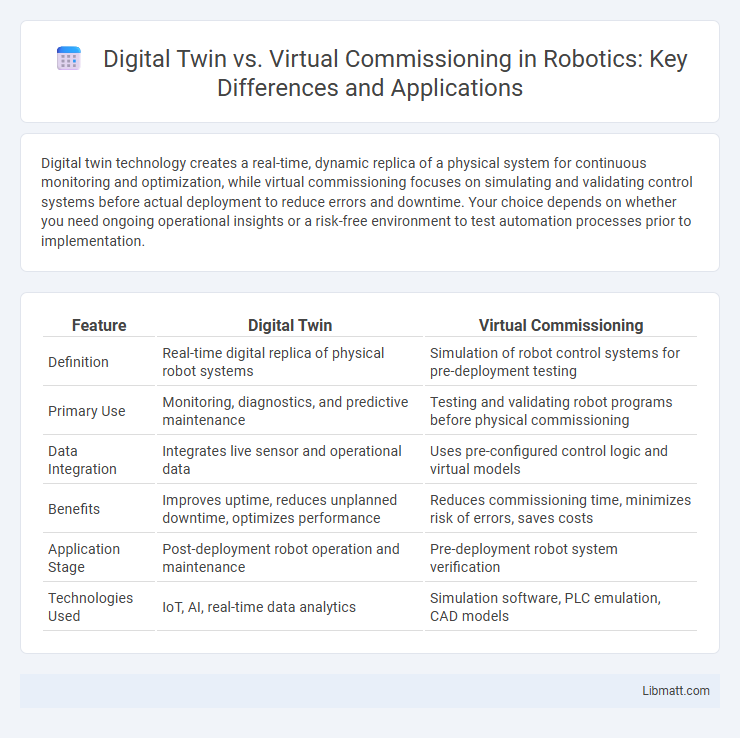

Digital twin technology creates a real-time, dynamic replica of a physical system for continuous monitoring and optimization, while virtual commissioning focuses on simulating and validating control systems before actual deployment to reduce errors and downtime. Your choice depends on whether you need ongoing operational insights or a risk-free environment to test automation processes prior to implementation.

Table of Comparison

| Feature | Digital Twin | Virtual Commissioning |

|---|---|---|

| Definition | Real-time digital replica of physical robot systems | Simulation of robot control systems for pre-deployment testing |

| Primary Use | Monitoring, diagnostics, and predictive maintenance | Testing and validating robot programs before physical commissioning |

| Data Integration | Integrates live sensor and operational data | Uses pre-configured control logic and virtual models |

| Benefits | Improves uptime, reduces unplanned downtime, optimizes performance | Reduces commissioning time, minimizes risk of errors, saves costs |

| Application Stage | Post-deployment robot operation and maintenance | Pre-deployment robot system verification |

| Technologies Used | IoT, AI, real-time data analytics | Simulation software, PLC emulation, CAD models |

Introduction to Digital Twin and Virtual Commissioning

Digital Twin is a precise digital replica of physical assets, processes, or systems that enables real-time monitoring, simulation, and analysis to optimize performance and predict maintenance needs. Virtual Commissioning uses simulation models to validate and test the control logic and systems of machinery or production lines before physical implementation, reducing commissioning time and cost. Your manufacturing processes benefit from integrating both technologies by enhancing system accuracy and operational efficiency before actual deployment.

Core Concepts: Digital Twin Explained

A digital twin is a dynamic, real-time virtual representation of a physical asset, system, or process, synchronizing data to mirror its behavior and performance accurately. It enables continuous monitoring, predictive maintenance, and optimization by integrating IoT sensors, machine learning, and simulation models. Unlike static simulations, digital twins evolve throughout the asset lifecycle, providing actionable insights for decision-making and operational efficiency.

Understanding Virtual Commissioning: Key Elements

Virtual commissioning involves creating a high-fidelity digital twin of a production system to simulate, test, and optimize machinery and control software before physical deployment. Key elements include accurate 3D modeling, real-time data integration, and synchronized control logic to replicate actual system behavior. This process reduces commissioning time, minimizes errors, and enhances system reliability by enabling thorough validation in a virtual environment.

Digital Twin vs Virtual Commissioning: Main Differences

Digital twin represents a real-time digital replica of a physical asset or system used for monitoring, analysis, and optimization throughout its lifecycle, while virtual commissioning focuses specifically on the pre-deployment testing and validation of control systems within a simulated environment. Digital twins enable continuous data exchange and predictive maintenance, whereas virtual commissioning reduces risk by identifying issues before actual hardware implementation. The primary difference lies in digital twin's ongoing operational insights versus virtual commissioning's role in the initial design and setup phase.

Benefits of Digital Twin in Industrial Automation

Digital twin technology enhances industrial automation by providing real-time, data-driven simulations that mirror physical assets, enabling predictive maintenance and reducing downtime. It improves operational efficiency through continuous monitoring and optimization of processes, leading to cost savings and increased productivity. Your ability to anticipate failures and optimize performance allows for smarter decision-making and accelerated innovation in manufacturing environments.

Advantages of Virtual Commissioning in Manufacturing

Virtual commissioning accelerates the manufacturing startup process by enabling thorough testing and validation of control systems in a simulated environment, minimizing errors and costly downtime. It allows your team to identify and resolve integration issues before physical equipment is deployed, improving overall system reliability and reducing risk. This approach enhances production efficiency and shortens time-to-market by ensuring that machines and processes are fully optimized prior to installation.

Use Cases: When to Use Digital Twin or Virtual Commissioning

Digital twins are ideal for real-time monitoring, predictive maintenance, and performance optimization of physical assets throughout their lifecycle, providing continuous data-driven insights. Virtual commissioning excels in validating control logic, system integration, and troubleshooting before physical equipment installation, reducing commissioning time and minimizing risks. You should use digital twins for operational efficiency and lifecycle management, while virtual commissioning is best suited for pre-deployment testing and ensuring system readiness.

Integration Challenges and Solutions

Digital twin and virtual commissioning face integration challenges such as data synchronization discrepancies, real-time communication latency, and compatibility between diverse software platforms. Solutions include adopting standardized protocols like OPC UA, implementing edge computing for faster data processing, and utilizing middleware to bridge heterogeneous systems. Your ability to seamlessly integrate these technologies enhances predictive maintenance and accelerates commissioning accuracy.

Future Trends: Digital Twin and Virtual Commissioning

Future trends in Digital Twin and Virtual Commissioning emphasize increased integration of AI and machine learning to enhance predictive analytics and real-time decision making. The adoption of cloud-based platforms and IoT connectivity enables more scalable, collaborative, and continuous simulation environments for manufacturing and industrial processes. Advances in augmented reality (AR) and digital thread technologies drive more immersive, accurate, and synchronized virtual commissioning, reducing time-to-market and operational costs.

Conclusion: Choosing the Right Approach for Your Business

Selecting between Digital Twin and Virtual Commissioning depends on your business goals, project complexity, and budget constraints. Digital Twin offers comprehensive real-time simulation and predictive analytics for continuous optimization, while Virtual Commissioning excels in pre-production testing and validation to reduce commissioning time and costs. Evaluating specific needs in system integration, scalability, and operational efficiency will guide the optimal choice for maximizing ROI and accelerating time-to-market.

Digital twin vs Virtual commissioning Infographic

libmatt.com

libmatt.com