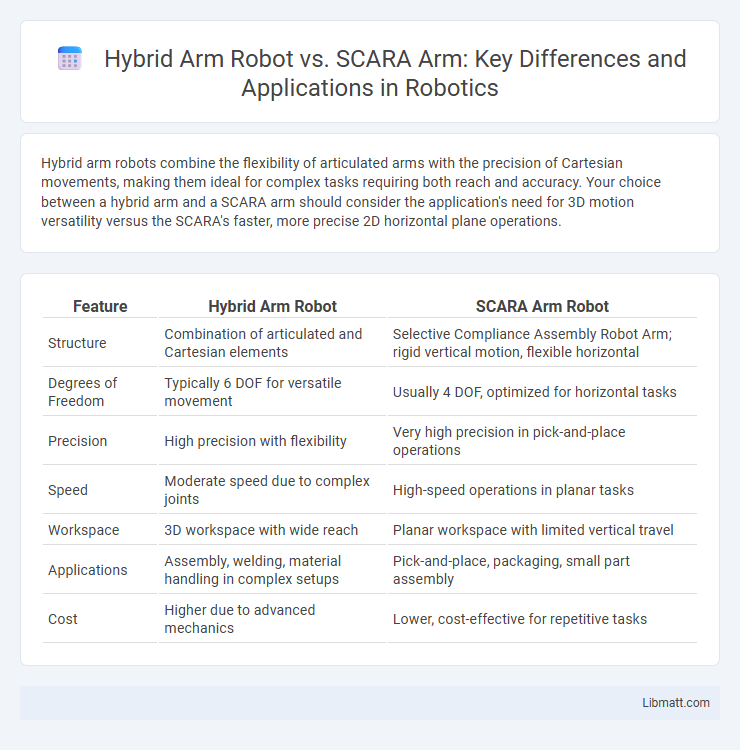

Hybrid arm robots combine the flexibility of articulated arms with the precision of Cartesian movements, making them ideal for complex tasks requiring both reach and accuracy. Your choice between a hybrid arm and a SCARA arm should consider the application's need for 3D motion versatility versus the SCARA's faster, more precise 2D horizontal plane operations.

Table of Comparison

| Feature | Hybrid Arm Robot | SCARA Arm Robot |

|---|---|---|

| Structure | Combination of articulated and Cartesian elements | Selective Compliance Assembly Robot Arm; rigid vertical motion, flexible horizontal |

| Degrees of Freedom | Typically 6 DOF for versatile movement | Usually 4 DOF, optimized for horizontal tasks |

| Precision | High precision with flexibility | Very high precision in pick-and-place operations |

| Speed | Moderate speed due to complex joints | High-speed operations in planar tasks |

| Workspace | 3D workspace with wide reach | Planar workspace with limited vertical travel |

| Applications | Assembly, welding, material handling in complex setups | Pick-and-place, packaging, small part assembly |

| Cost | Higher due to advanced mechanics | Lower, cost-effective for repetitive tasks |

Introduction to Hybrid Arm Robots and SCARA Arms

Hybrid arm robots combine the flexibility of articulated arms with the precision of linear actuators, enabling complex multi-axis movements ideal for diverse industrial tasks. SCARA (Selective Compliance Assembly Robot Arm) arms excel in high-speed, precise horizontal movements, making them perfect for pick-and-place and assembly applications. Your choice between these robotic arms depends on the complexity of motion required and the task-specific accuracy needed.

Key Structural Differences

Hybrid arm robots combine Cartesian and articulated mechanisms, offering multi-axis motion with increased flexibility and reach, while SCARA (Selective Compliance Assembly Robot Arm) robots feature a rigid vertical axis and compliant horizontal axes designed primarily for precise, fast, planar movements. The structural design of hybrid arms allows for complex, three-dimensional tasks by integrating linear and rotary components, contrasting SCARA arms' simpler, two or three-axis configurations optimized for horizontal assembly operations. These key structural differences directly impact their suitability for applications requiring either versatile spatial manipulation or rapid, repeatable planar positioning.

Degrees of Freedom Comparison

The Hybrid arm robot typically offers 6 degrees of freedom, providing enhanced flexibility and a wider range of motion suited for complex tasks such as assembly and machining. In contrast, SCARA (Selective Compliance Assembly Robot Arm) robots generally have 4 degrees of freedom, optimized for high-speed, precise horizontal movements in pick-and-place and packaging applications. This difference in degrees of freedom directly impacts the versatility and application scope of each robot type in industrial automation.

Precision and Accuracy

Hybrid arm robots combine the flexibility of articulated arms with the speed and repeatability of Cartesian systems, offering enhanced precision and accuracy in complex tasks. SCARA arms excel in high-speed, high-precision assembly with consistent repeatability, especially in planar movements, delivering tight positional control ideal for pick-and-place operations. Your choice depends on whether you prioritize multi-axis versatility or rapid, precise horizontal motion within your automated processes.

Speed and Performance

Hybrid arm robots combine the flexibility of articulated arms with the speed of Cartesian systems, offering enhanced performance for complex tasks requiring rapid, precise movements. SCARA arms excel in speed for horizontal pick-and-place operations, delivering high throughput due to their rigid structure and efficient kinematics. Your choice should consider the task complexity and speed requirements, as hybrid arms provide versatile motion paths while SCARA robots maximize speed in planar movements.

Flexibility and Application Range

Hybrid arm robots offer greater flexibility and a wider application range compared to SCARA arms, as they combine the strengths of Cartesian and articulated robots to perform complex, multi-axis tasks with high precision. SCARA arms excel in high-speed, repetitive pick-and-place operations within a limited, horizontal workspace but lack the versatility to handle diverse 3D movements or intricate assembly processes. Your choice depends on whether your application demands adaptability in complex environments or optimized efficiency in simpler, planar tasks.

Payload Capacity

Hybrid arm robots typically offer higher payload capacity compared to SCARA arms, making them suitable for handling heavier materials in industrial applications. While SCARA arms excel in speed and precision for lightweight tasks, their payload capacity generally ranges from 3 to 10 kilograms. Hybrid arm robots, combining articulated and linear actuator features, can support payloads beyond 20 kilograms, providing greater versatility for complex assembly and machining operations.

Integration and Control Systems

Hybrid arm robots combine the flexibility of articulated arms with the precision of Cartesian movement, requiring advanced integration and control systems that synchronize multiple types of actuators and sensor feedback for seamless operation. SCARA arms utilize simpler, highly efficient control architectures optimized for horizontal movements, enabling faster and more precise pick-and-place tasks with lower implementation complexity. Your choice between these robotic arms depends on whether you prioritize complex motion integration or streamlined control for specific industrial applications.

Cost and Maintenance Considerations

Hybrid arm robots generally incur higher initial costs compared to SCARA arms due to their complex multi-axis design and advanced capabilities. Maintenance expenses for hybrid robots can also be higher because of intricate mechanical parts requiring specialized servicing, whereas SCARA robots benefit from simpler structures that reduce downtime and upkeep costs. Evaluating your specific application needs helps determine the best balance between investment and operational expenses.

Choosing the Right Robotic Arm for Your Application

Selecting the right robotic arm depends heavily on your application's requirements such as precision, speed, and range of motion. Hybrid arms combine the versatility and dexterity of articulated arms with the speed and repeatability of SCARA arms, making them ideal for complex tasks requiring multiple degrees of freedom. If your task requires high-speed, horizontal movement with moderate precision, a SCARA arm typically offers better cost-efficiency and simplicity for your manufacturing or assembly processes.

Hybrid arm robot vs SCARA arm Infographic

libmatt.com

libmatt.com