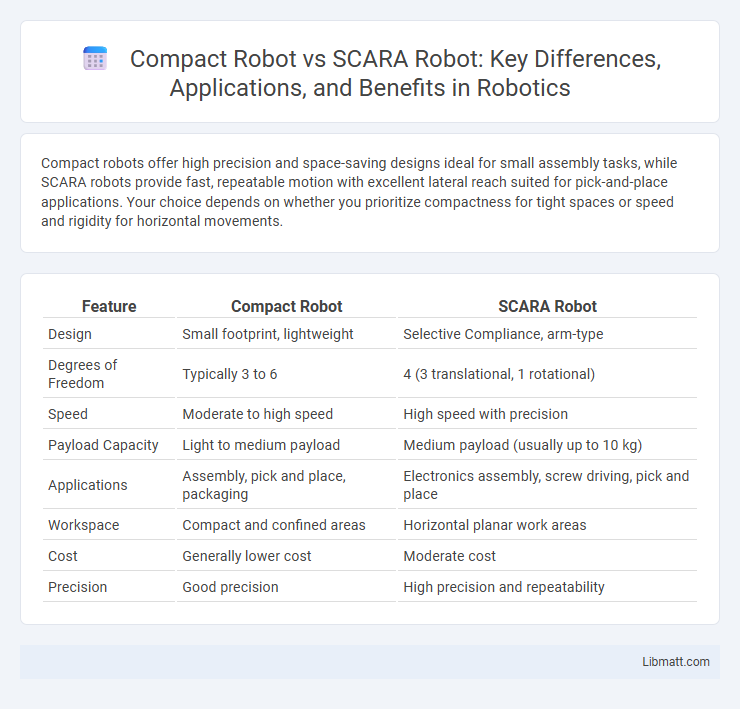

Compact robots offer high precision and space-saving designs ideal for small assembly tasks, while SCARA robots provide fast, repeatable motion with excellent lateral reach suited for pick-and-place applications. Your choice depends on whether you prioritize compactness for tight spaces or speed and rigidity for horizontal movements.

Table of Comparison

| Feature | Compact Robot | SCARA Robot |

|---|---|---|

| Design | Small footprint, lightweight | Selective Compliance, arm-type |

| Degrees of Freedom | Typically 3 to 6 | 4 (3 translational, 1 rotational) |

| Speed | Moderate to high speed | High speed with precision |

| Payload Capacity | Light to medium payload | Medium payload (usually up to 10 kg) |

| Applications | Assembly, pick and place, packaging | Electronics assembly, screw driving, pick and place |

| Workspace | Compact and confined areas | Horizontal planar work areas |

| Cost | Generally lower cost | Moderate cost |

| Precision | Good precision | High precision and repeatability |

Introduction to Compact Robots and SCARA Robots

Compact robots are designed for space-efficient automation tasks, offering high precision and flexibility in limited workspaces, making them ideal for electronics assembly and small-part handling. SCARA robots (Selective Compliance Assembly Robot Arm) specialize in lateral movements with a rigid vertical axis, excelling in fast, repetitive pick-and-place operations and precise assembly applications in automotive and manufacturing industries. Both robot types enhance productivity by optimizing space and motion control tailored to specific industrial automation needs.

Design Architecture: Compact vs SCARA Robots

Compact robots feature a streamlined, space-saving design ideal for tight workspaces, emphasizing versatility and ease of integration. SCARA robots adopt a rigid, horizontal arm architecture with high precision and speed, suited for pick-and-place tasks in assembly lines. Your choice depends on the specific layout constraints and operational needs of your automation process.

Space Efficiency and Footprint Comparison

Compact robots excel in space efficiency due to their smaller footprints, making them ideal for applications with limited workspace. SCARA robots typically require more installation space because of their articulated arm design, which covers a larger operational range but increases footprint size. Your choice should consider the available floor area and the specific task requirements to optimize productivity while minimizing spatial impact.

Flexibility in Industrial Applications

Compact robots offer greater flexibility in industrial applications due to their smaller footprint and ability to operate in tight spaces, making them ideal for tasks requiring precision and agility. SCARA robots excel in high-speed assembly and pick-and-place operations with consistent repeatability, but their rigid design limits adaptability to varying tasks. Your choice between these robots should consider the complexity and variability of your applications to maximize operational efficiency.

Speed and Precision Performance

Compact robots typically offer moderate speed and precision, optimized for space-constrained applications with payloads under 10 kg. SCARA robots excel in high-speed assembly tasks, achieving cycle times as low as 0.5 seconds with repeatability accuracy within +-0.01 mm. The rigidity and articulated arm design of SCARA robots enable superior precision and faster motion compared to most compact robots, making them ideal for electronics and small parts manufacturing.

Cost of Implementation and Maintenance

Compact robots typically have a lower cost of implementation due to their smaller size and simpler integration requirements, making them ideal for budget-conscious manufacturing setups. SCARA robots, while generally more expensive upfront, offer enhanced precision and speed which can reduce long-term maintenance costs through improved reliability and less downtime. Your choice should consider the balance between initial investment and ongoing maintenance expenses to optimize operational efficiency.

Ease of Programming and Integration

Compact robots offer straightforward programming with intuitive interfaces ideal for simple, repetitive tasks, making integration into existing production lines quick and efficient. SCARA robots provide advanced programming flexibility suitable for complex, high-speed assembly operations, requiring specialized knowledge but enabling seamless integration with automated systems. Your choice depends on the specific complexity of your application and the desired balance between programming ease and system integration depth.

Typical Use Cases for Compact Robots

Compact robots are ideal for precise assembly tasks, small part handling, and electronics manufacturing due to their space-saving design and high repeatability. Their versatility allows deployment in laboratories for sample manipulation and medical device production where cleanroom compatibility is essential. Compact robots excel in applications requiring fast cycle times and flexibility within limited workspace environments.

Typical Use Cases for SCARA Robots

SCARA robots excel in high-speed assembly, pick-and-place tasks, and precision electronic manufacturing due to their rigid structure and fast lateral movements. Their design enables precise vertical movements ideal for tasks like screw driving, packaging, and component insertion in automotive and consumer electronics industries. You benefit from SCARA robots' ability to boost productivity in environments requiring rapid, repetitive motion with consistent accuracy.

Choosing the Right Robot: Key Decision Factors

Choosing the right robot depends on application requirements such as workspace configuration, payload capacity, and speed. Compact robots excel in limited spaces with high precision for light-duty tasks, while SCARA robots offer greater reach and faster cycle times suited for assembly and pick-and-place operations. Evaluating factors like repeatability, footprint size, and integration ease ensures optimal robot selection for manufacturing efficiency.

Compact robot vs SCARA robot Infographic

libmatt.com

libmatt.com