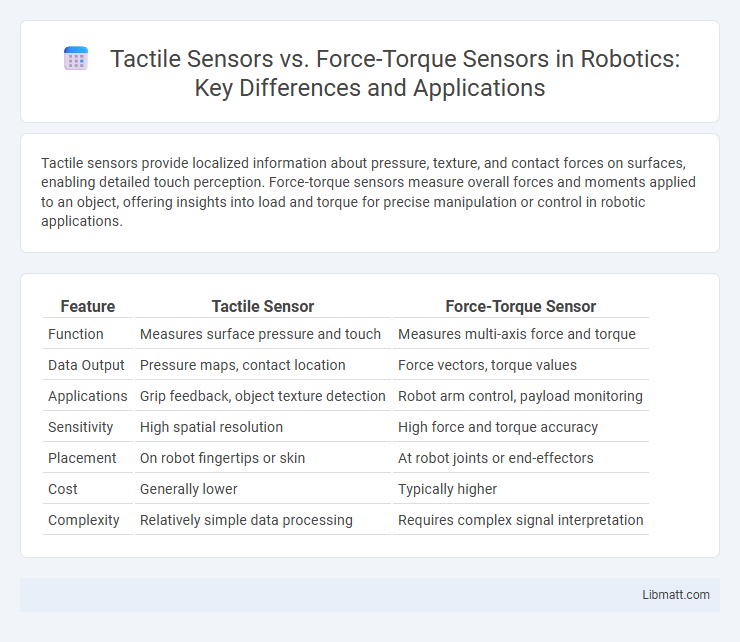

Tactile sensors provide localized information about pressure, texture, and contact forces on surfaces, enabling detailed touch perception. Force-torque sensors measure overall forces and moments applied to an object, offering insights into load and torque for precise manipulation or control in robotic applications.

Table of Comparison

| Feature | Tactile Sensor | Force-Torque Sensor |

|---|---|---|

| Function | Measures surface pressure and touch | Measures multi-axis force and torque |

| Data Output | Pressure maps, contact location | Force vectors, torque values |

| Applications | Grip feedback, object texture detection | Robot arm control, payload monitoring |

| Sensitivity | High spatial resolution | High force and torque accuracy |

| Placement | On robot fingertips or skin | At robot joints or end-effectors |

| Cost | Generally lower | Typically higher |

| Complexity | Relatively simple data processing | Requires complex signal interpretation |

Introduction to Tactile and Force-Torque Sensors

Tactile sensors detect surface contact properties such as pressure, texture, and vibration, providing detailed spatial information about touch interactions. Force-torque sensors measure multi-axis forces and moments at a single point, supplying precise data on mechanical loads and interactions in robotic arms and industrial applications. Both sensor types are essential in robotics for enhancing manipulation, grip control, and interaction with environments, but they differ in measurement scope and application focus.

Understanding Tactile Sensors: Principles and Applications

Tactile sensors detect surface texture, pressure, and vibration by mimicking the human sense of touch, using arrays of microelectromechanical systems (MEMS) or piezoresistive materials to capture detailed contact information. In contrast, force-torque sensors measure the magnitude and direction of forces and torques applied to an object, providing critical data for robotic manipulation and control. Understanding tactile sensors allows you to enhance robotic perception and interaction by integrating precise touch feedback into automation and prosthetics applications.

Force-Torque Sensors: Functionality and Use Cases

Force-torque sensors measure multi-axis forces and torques applied to a structure, enabling precise detection of interaction forces in robotics and industrial automation. Their functionality includes monitoring load dynamics, ensuring safety in human-robot collaboration, and improving control accuracy in assembly and machining tasks. You can leverage these sensors for real-time feedback in applications requiring high sensitivity to multidirectional forces.

Key Differences Between Tactile and Force-Torque Sensors

Tactile sensors measure surface contact properties such as pressure distribution, texture, and slip, providing high-resolution spatial information critical for object manipulation and texture recognition. Force-torque sensors detect overall external forces and moments acting on an object or robotic joint, enabling precise measurement of load, balance, and stability in multi-axis directions. The primary difference lies in tactile sensors' localized surface detection versus force-torque sensors' global force and torque measurement capabilities.

Measurement Capabilities: Pressure vs. Force and Torque

Tactile sensors primarily measure localized pressure distribution and surface contact conditions, enabling detailed detection of touch and texture variations. Force-torque sensors quantify overall force vectors and moments applied to an object, capturing magnitude and direction of applied forces and torques across multiple axes. Understanding the distinction between pressure measurement in tactile sensors and multi-axis force and torque measurement in force-torque sensors is critical for applications in robotics and haptic feedback systems.

Sensitivity and Resolution Comparison

Tactile sensors generally offer higher spatial resolution, enabling detailed detection of surface textures and subtle pressure variations, while force-torque sensors provide broader sensitivity to overall force and torque magnitudes across multiple axes. The sensitivity of tactile sensors is optimized for localized contact events at micro- to milli-Newton levels, whereas force-torque sensors excel in measuring larger forces typically ranging from Newtons to kiloNewtons with high accuracy. The resolution of tactile sensors allows for fine-grained pressure mapping essential for tasks like object recognition and manipulation, contrasting with force-torque sensors that prioritize precise vector measurements for dynamic load analysis and control.

Integration in Robotics and Automation Systems

Tactile sensors provide localized contact information critical for delicate object manipulation, enabling robots to adjust grip and detect slippage in real-time within automation systems. Force-torque sensors measure overall force and torque at the robot's joints or end-effectors, essential for tasks requiring precise force control like assembly or machining. Integration of both sensors enhances robotic performance by combining detailed tactile feedback with comprehensive force measurement, improving adaptability and safety in complex industrial applications.

Advantages of Tactile Sensors Over Force-Torque Sensors

Tactile sensors provide high-resolution spatial sensing capabilities that enable precise detection of contact location and texture, outperforming force-torque sensors which primarily measure overall force and torque without detailed surface information. Their compact size and flexibility allow integration in complex robotic fingertips and wearable devices, enhancing dexterity and user interaction in prosthetics and robotics. Tactile sensors also offer real-time feedback for dynamic manipulation tasks, improving object handling and grip stability compared to the broader, less localized measurements of force-torque sensors.

Advantages of Force-Torque Sensors Over Tactile Sensors

Force-torque sensors provide precise measurement of multi-axis forces and torques, enabling accurate control in robotic applications where load feedback is critical. Their robust design allows for direct force and moment detection without complex signal interpretation required by tactile sensor arrays. These sensors offer superior durability and reliability in harsh environments compared to tactile sensors, which are often sensitive to surface damage and have limited spatial resolution.

Choosing the Right Sensor: Application-Based Recommendations

Tactile sensors excel in applications requiring high-resolution surface texture detection and precise contact force mapping, making them ideal for robotic skin and delicate object manipulation. Force-torque sensors are better suited for tasks involving multi-axis force and moment measurements, such as robotic arm control and industrial automation where robust load assessment is critical. Selecting the right sensor depends on factors like sensitivity requirements, spatial resolution, and the specific force components to measure within the operational environment.

Tactile sensor vs Force-torque sensor Infographic

libmatt.com

libmatt.com