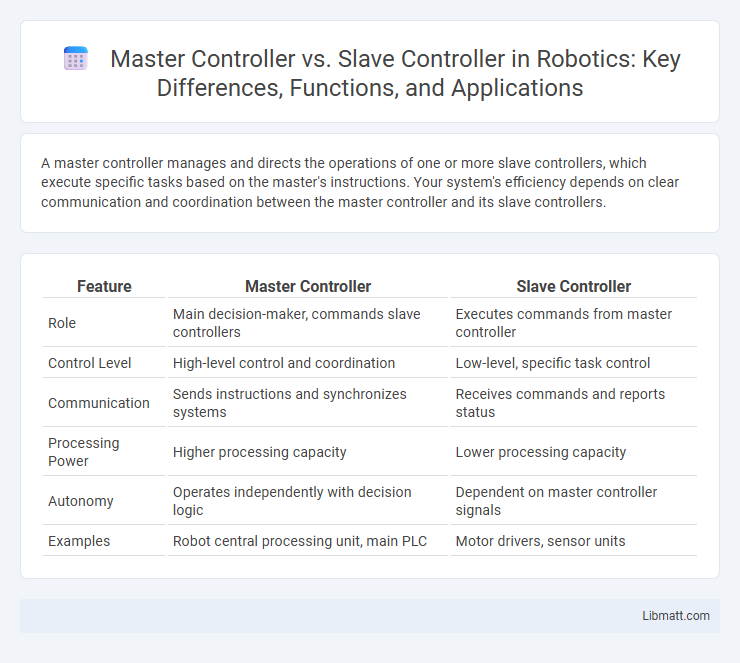

A master controller manages and directs the operations of one or more slave controllers, which execute specific tasks based on the master's instructions. Your system's efficiency depends on clear communication and coordination between the master controller and its slave controllers.

Table of Comparison

| Feature | Master Controller | Slave Controller |

|---|---|---|

| Role | Main decision-maker, commands slave controllers | Executes commands from master controller |

| Control Level | High-level control and coordination | Low-level, specific task control |

| Communication | Sends instructions and synchronizes systems | Receives commands and reports status |

| Processing Power | Higher processing capacity | Lower processing capacity |

| Autonomy | Operates independently with decision logic | Dependent on master controller signals |

| Examples | Robot central processing unit, main PLC | Motor drivers, sensor units |

Introduction to Master and Slave Controllers

Master and slave controllers are key components in automation and control systems, where the master controller manages overall system operations by sending commands, while the slave controller executes specific tasks or processes as directed. Master controllers coordinate multiple slave units to ensure synchronized and efficient performance in complex setups, such as industrial machinery or robotics. Your understanding of these controllers is essential for optimizing control hierarchies and achieving precise system control.

Defining Master Controller

A Master controller is a central device in a control system responsible for managing and directing the operation of subordinate controllers, known as Slave controllers. It interprets input data, executes control algorithms, and sends commands to ensure coordinated system performance. Master controllers are crucial in industrial automation, robotics, and communication networks where hierarchical control structures improve efficiency and reliability.

Defining Slave Controller

A Slave Controller operates under the direction of a Master Controller, executing commands without independent decision-making capabilities. It functions as a subordinate in control systems, receiving instructions to perform specific tasks such as data collection or actuator control. Understanding the role of a Slave Controller is essential for optimizing system communication and ensuring synchronized operation within your network.

Key Differences Between Master and Slave Controllers

Master controllers initiate commands and manage communication protocols, while slave controllers respond to those commands without initiating interactions. Master controllers have the authority to control and synchronize multiple slave devices, ensuring coherent system operation. Slave controllers operate under the directives of the master, typically executing specific tasks as instructed within industrial automation or communication networks.

Advantages of Master Controller

A Master Controller offers centralized control, enhancing system coordination and reducing complexity by managing multiple Slave Controllers efficiently. It improves system reliability through real-time data processing and decision-making, enabling faster response times and streamlined operations. Your automation setup benefits from easier scalability and simplified troubleshooting, making the Master Controller a critical component in industrial control systems.

Advantages of Slave Controller

Slave controllers offer the advantage of offloading tasks from the master controller, enhancing overall system efficiency and responsiveness. By managing specific functions independently, slave controllers reduce communication bottlenecks and improve scalability in complex automation networks. Your system benefits from increased reliability and easier troubleshooting since faults can be isolated within individual slave units.

Typical Applications for Master-Slave Architectures

Master-slave controller architectures are widely used in industrial automation systems where precise coordination and hierarchical control are essential, such as in CNC machines and robotic assembly lines. These controllers enable centralized decision-making by the master, while slave units execute specific tasks, optimizing efficiency and reliability in process control and factory automation. Your control systems benefit from enhanced scalability and fault tolerance when applying master-slave configurations in distributed networks like HVAC or automotive manufacturing.

Communication Protocols in Master-Slave Systems

Communication protocols in master-slave systems define the rules and timing for data exchange, with the master controller initiating commands and the slave controller responding accordingly. Common protocols like Modbus, PROFIBUS, and I2C enable synchronized communication, ensuring accurate device addressing, error checking, and data integrity. Protocol efficiency impacts system performance by managing bus arbitration, transmission speed, and fault tolerance in real-time industrial and embedded applications.

Challenges in Master-Slave Controller Implementation

Master-slave controller implementations face challenges such as synchronization issues, where the slave must accurately follow the master's commands without delay or error, impacting system responsiveness. Communication failures between master and slave controllers can cause data loss or incorrect signal interpretation, leading to system instability or malfunction. Scalability limitations arise because adding more slaves increases complexity in coordination and control, demanding robust protocols to maintain performance and reliability in large networks.

Future Trends in Controller Architectures

Future trends in controller architectures emphasize the transition from traditional master-slave configurations to more decentralized and intelligent systems, leveraging artificial intelligence and edge computing for enhanced autonomy and responsiveness. Adaptive controller networks enable real-time decision-making and fault tolerance, improving system scalability and efficiency. Your control systems will benefit from these advancements by achieving greater flexibility and reduced latency in complex industrial and IoT environments.

Master controller vs Slave controller Infographic

libmatt.com

libmatt.com