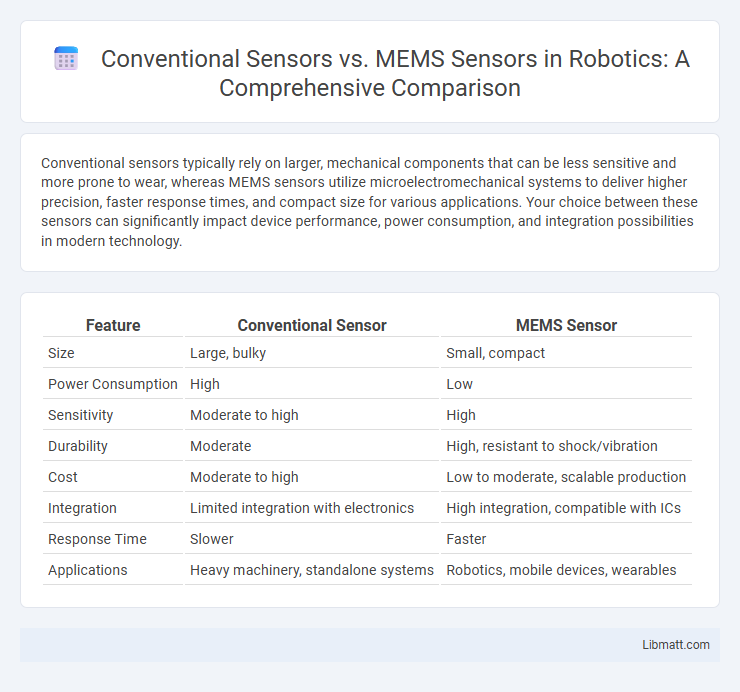

Conventional sensors typically rely on larger, mechanical components that can be less sensitive and more prone to wear, whereas MEMS sensors utilize microelectromechanical systems to deliver higher precision, faster response times, and compact size for various applications. Your choice between these sensors can significantly impact device performance, power consumption, and integration possibilities in modern technology.

Table of Comparison

| Feature | Conventional Sensor | MEMS Sensor |

|---|---|---|

| Size | Large, bulky | Small, compact |

| Power Consumption | High | Low |

| Sensitivity | Moderate to high | High |

| Durability | Moderate | High, resistant to shock/vibration |

| Cost | Moderate to high | Low to moderate, scalable production |

| Integration | Limited integration with electronics | High integration, compatible with ICs |

| Response Time | Slower | Faster |

| Applications | Heavy machinery, standalone systems | Robotics, mobile devices, wearables |

Introduction to Conventional and MEMS Sensors

Conventional sensors utilize bulky, discrete components to measure physical phenomena such as temperature, pressure, and acceleration, often resulting in slower response times and higher power consumption. MEMS (Micro-Electro-Mechanical Systems) sensors integrate mechanical elements, sensors, and electronics on a single silicon chip, enabling miniaturization, enhanced sensitivity, and lower energy usage. The shift to MEMS technology revolutionizes sensing applications in automotive, healthcare, and consumer electronics by offering improved accuracy, durability, and cost efficiency.

Fundamental Working Principles

Conventional sensors typically rely on macroscopic physical effects such as resistance changes, capacitance variations, or inductive coupling to detect environmental changes, often using discrete components and mechanical parts. MEMS sensors operate based on microscale electromechanical structures fabricated through semiconductor processes, utilizing principles like piezoresistivity, capacitive sensing, and resonant frequency shifts within integrated microsystems. The miniaturization of MEMS sensors enables higher sensitivity and faster response times compared to traditional sensors by leveraging microfabricated mechanical elements and integrated circuitry.

Key Differences in Design and Structure

Conventional sensors typically rely on bulk materials and macroscopic structures, resulting in larger size and less integration capability compared to MEMS sensors, which use microfabrication techniques to create highly miniaturized mechanical and electrical components on a single chip. MEMS sensors exhibit improved sensitivity and faster response times due to their microscale cantilevers, beams, or membranes combined with integrated circuits, whereas conventional sensors depend on discrete components and larger-scale mechanisms. The structural design of MEMS sensors enables lower power consumption and higher reliability in harsh environments, contrasting with the often bulkier, less robust architecture of traditional sensor technologies.

Performance Comparison: Accuracy and Sensitivity

MEMS sensors offer higher sensitivity and improved accuracy compared to conventional sensors due to their miniaturized design and advanced fabrication techniques. Conventional sensors often suffer from larger signal noise and slower response times, limiting their precision in dynamic environments. MEMS technology enables enhanced measurement resolution and reduced drift, making it ideal for applications requiring precise and reliable sensor data.

Size, Weight, and Power Consumption

MEMS sensors are significantly smaller and lighter than conventional sensors, enabling integration into compact and portable devices with minimal space requirements. Their low power consumption makes them ideal for battery-operated applications, extending device operational time compared to traditional sensors that consume more energy. The microscale fabrication techniques used in MEMS technology reduce size and weight without compromising sensitivity and performance.

Manufacturing Techniques and Scalability

Conventional sensors rely on bulk machining and discrete component assembly, resulting in higher manufacturing costs and limited scalability due to complex processes. MEMS sensors utilize microfabrication techniques such as photolithography and etching on semiconductor wafers, enabling mass production with precise miniaturization and uniformity. You benefit from MEMS sensors' cost-effective scalability and integration potential in various applications, outperforming traditional sensor manufacturing methods.

Cost Analysis: Production and Maintenance

Conventional sensors typically incur higher production costs due to bulkier materials and more complex manufacturing processes, whereas MEMS (Micro-Electro-Mechanical Systems) sensors benefit from batch fabrication techniques on semiconductor wafers, significantly reducing unit costs. Maintenance expenses for conventional sensors are often elevated because of their susceptibility to mechanical wear and limited integration capabilities, while MEMS sensors offer enhanced reliability and lower maintenance needs due to their miniaturized, robust design and integrated electronics. The scalability and precision manufacturing of MEMS sensors drive cost-efficiency in both production and long-term operation, making them more economical for high-volume applications.

Application Areas and Industry Adoption

Conventional sensors are widely used in traditional industrial automation, automotive systems, and environmental monitoring due to their established reliability and robustness. MEMS (Micro-Electro-Mechanical Systems) sensors dominate consumer electronics, medical devices, and aerospace applications because of their miniaturization, low power consumption, and high sensitivity. Industry adoption of MEMS sensors is rapidly growing in IoT, wearable technology, and smart manufacturing, driven by integration capabilities and cost efficiency.

Future Trends in Sensor Technology

Future trends in sensor technology emphasize the miniaturization and integration capabilities of MEMS sensors over conventional sensors, enabling higher precision and multifunctionality in compact forms. Advances in MEMS sensor materials and fabrication processes drive enhanced sensitivity and energy efficiency, critical for IoT and wearable applications. The shift towards smart sensors with embedded AI algorithms is expected to revolutionize real-time data analysis and predictive maintenance across industries.

Conclusion: Choosing the Right Sensor

Conventional sensors excel in durability and simplicity for basic applications, while MEMS sensors offer advanced miniaturization, higher precision, and integration capabilities suited for modern technology. Your decision should consider factors like size constraints, environmental conditions, accuracy requirements, and cost efficiency. Selecting the right sensor ensures optimal performance tailored to your specific project needs and long-term reliability.

Conventional sensor vs MEMS sensor Infographic

libmatt.com

libmatt.com