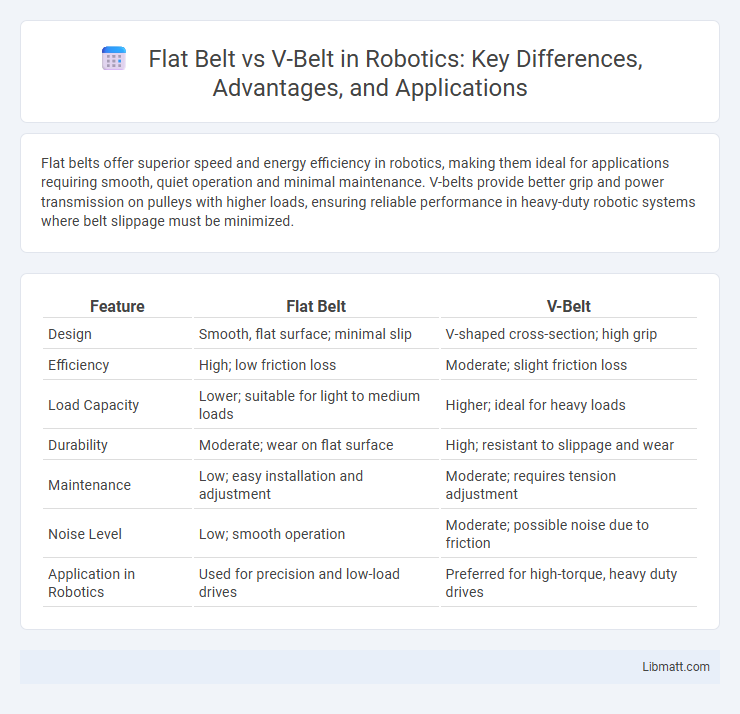

Flat belts offer superior speed and energy efficiency in robotics, making them ideal for applications requiring smooth, quiet operation and minimal maintenance. V-belts provide better grip and power transmission on pulleys with higher loads, ensuring reliable performance in heavy-duty robotic systems where belt slippage must be minimized.

Table of Comparison

| Feature | Flat Belt | V-Belt |

|---|---|---|

| Design | Smooth, flat surface; minimal slip | V-shaped cross-section; high grip |

| Efficiency | High; low friction loss | Moderate; slight friction loss |

| Load Capacity | Lower; suitable for light to medium loads | Higher; ideal for heavy loads |

| Durability | Moderate; wear on flat surface | High; resistant to slippage and wear |

| Maintenance | Low; easy installation and adjustment | Moderate; requires tension adjustment |

| Noise Level | Low; smooth operation | Moderate; possible noise due to friction |

| Application in Robotics | Used for precision and low-load drives | Preferred for high-torque, heavy duty drives |

Introduction to Belt Drives in Robotics

Belt drives in robotics are essential for power transmission between rotating shafts, with flat belts and V-belts being the most common types. Flat belts offer high-speed operation and smooth, low-friction motion, ideal for precise robotic movements, while V-belts provide superior grip and torque transmission due to their trapezoidal cross-section. Understanding the differences helps you select the optimal belt drive to enhance efficiency and reliability in your robotic systems.

Overview of Flat Belts

Flat belts in robotics offer a smooth, high-speed transmission suitable for precise motion control and minimal slippage. Their broad, flat surface distributes tension evenly, reducing wear and enhancing durability compared to V-belts. Commonly made from materials like polyurethane or rubber reinforced with fabric, flat belts excel in applications requiring quiet operation and consistent power delivery.

Overview of V-Belts

V-belts are widely used in robotics for power transmission due to their trapezoidal cross-section, which provides high friction and efficient torque transfer between pulleys. Their design allows for self-centering action and reduces slippage, making them ideal for dynamic robotic systems requiring precise motion control. Your robotic applications benefit from V-belts' durability and ability to handle moderate to high loads with consistent performance.

Efficiency Comparison: Flat Belt vs V-Belt

Flat belts in robotics offer higher efficiency due to their lower friction and reduced slippage compared to V-belts, resulting in better power transmission and energy savings. V-belts provide greater grip and are more effective under heavy loads or shock loads, but this often comes with increased energy loss and maintenance requirements. For your robotic applications demanding consistent and smooth torque transfer, flat belts can optimize performance by minimizing energy waste.

Load Handling Capabilities

Flat belts offer superior load handling capabilities in robotics due to their larger contact surface area, reducing slippage and distributing tension more evenly across the belt. V-belts, with their wedge-shaped design, provide excellent grip for high torque applications but can experience higher wear under heavy loads. Your choice between flat and V-belts should consider the specific load requirements and precision needed for optimal robotic performance.

Space and Design Considerations

Flat belts offer a lower profile and greater flexibility, making them ideal for compact robotic designs where minimizing space is crucial. V-belts provide higher torque transmission with a smaller groove contact, suitable for applications that require precise power transfer within limited design constraints. The choice between flat and V-belts directly impacts the spatial efficiency and mechanical layout of robotic systems, influencing overall performance and maintenance complexity.

Maintenance and Longevity

Flat belts in robotics typically require less frequent maintenance due to their simpler design and reduced slippage, enhancing operational longevity. V-belts, although more prone to wear and requiring regular tension adjustments, offer superior grip and power transmission for high-torque applications. Choosing the right belt for your robotic system impacts both maintenance schedules and equipment lifespan, ensuring optimal performance and durability.

Cost Analysis: Flat Belt vs V-Belt

Flat belts typically offer a lower initial cost and require less maintenance in robotics applications, making them a cost-effective choice for long-term use. V-belts, while generally more expensive upfront, provide superior power transmission and durability, reducing wear and potential downtime in heavy-load scenarios. Your decision should balance the upfront investment against operational efficiency and maintenance expenses based on the specific demands of your robotic system.

Application Scenarios in Robotics

Flat belts excel in robotics applications requiring high-speed, low-torque power transmission with minimal slippage, such as conveyor systems and packaging robots. V-belts are ideal for scenarios needing higher torque transmission and better grip, including robotic arms and heavy-duty industrial automation. Choosing the right belt optimizes your robot's efficiency and durability in its specific operational environment.

Choosing the Right Belt for Robotic Systems

Selecting the right belt for robotic systems involves comparing flat belts and V-belts based on factors such as load capacity, efficiency, and maintenance requirements. Flat belts offer high-speed operation with reduced slippage and are ideal for lightweight, precision robotics, while V-belts provide greater torque transmission and durability suitable for heavier loads and industrial applications. Your choice should consider the specific robot's power demands, alignment tolerance, and environmental conditions to optimize performance and longevity.

Flat Belt vs V-Belt in Robotics Infographic

libmatt.com

libmatt.com