Static calibration measures sensor accuracy under fixed, controlled conditions to ensure precise baseline readings, while dynamic calibration evaluates performance during actual movement or varying operational states to reflect real-world functionality. Understanding the differences between static calibration and dynamic calibration helps you choose the appropriate method to maintain optimal device reliability and accuracy.

Table of Comparison

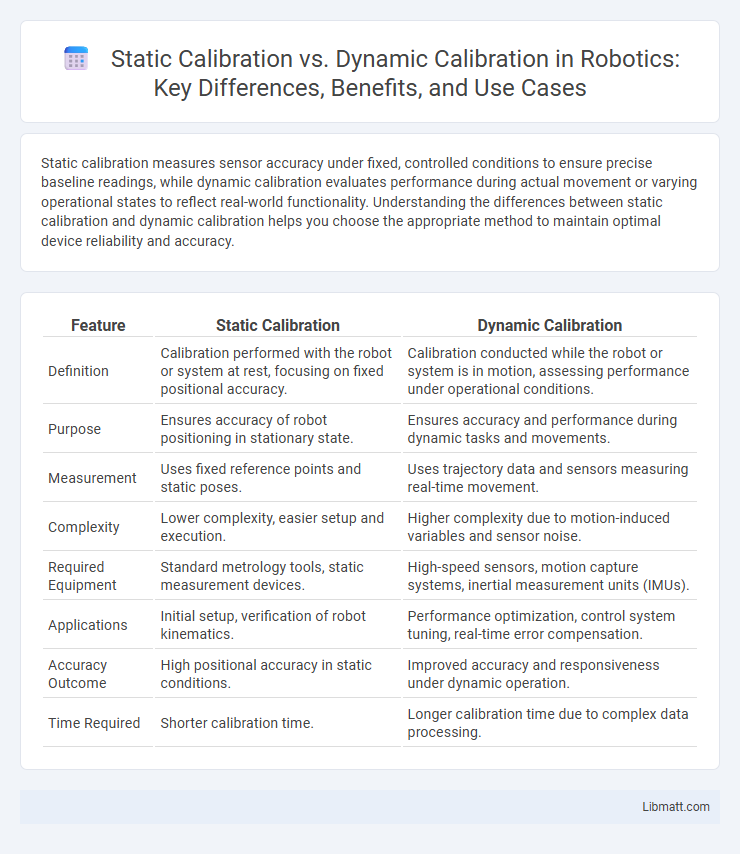

| Feature | Static Calibration | Dynamic Calibration |

|---|---|---|

| Definition | Calibration performed with the robot or system at rest, focusing on fixed positional accuracy. | Calibration conducted while the robot or system is in motion, assessing performance under operational conditions. |

| Purpose | Ensures accuracy of robot positioning in stationary state. | Ensures accuracy and performance during dynamic tasks and movements. |

| Measurement | Uses fixed reference points and static poses. | Uses trajectory data and sensors measuring real-time movement. |

| Complexity | Lower complexity, easier setup and execution. | Higher complexity due to motion-induced variables and sensor noise. |

| Required Equipment | Standard metrology tools, static measurement devices. | High-speed sensors, motion capture systems, inertial measurement units (IMUs). |

| Applications | Initial setup, verification of robot kinematics. | Performance optimization, control system tuning, real-time error compensation. |

| Accuracy Outcome | High positional accuracy in static conditions. | Improved accuracy and responsiveness under dynamic operation. |

| Time Required | Shorter calibration time. | Longer calibration time due to complex data processing. |

Introduction to Calibration: Static vs Dynamic

Static calibration involves adjusting and verifying measurement instruments under fixed conditions without movement, ensuring accuracy in stable environments. Dynamic calibration, in contrast, tests and calibrates instruments under varying operational conditions, capturing performance during real-time motion or changing variables. Understanding these approaches helps you select the appropriate calibration method to maintain precision and reliability in your specific application.

Defining Static Calibration

Static calibration involves adjusting measurement instruments or sensors while they remain stationary to ensure accurate readings under fixed conditions. This process establishes baseline accuracy by comparing outputs against known reference standards without motion influences. Your equipment's reliability significantly improves through precise static calibration before dynamic calibration is considered.

Understanding Dynamic Calibration

Dynamic calibration involves adjusting measurement instruments in real-time conditions, reflecting actual operating environments to enhance accuracy. Unlike static calibration, which uses fixed reference points, dynamic calibration accounts for varying factors such as temperature, motion, and load changes that impact sensor performance. Understanding dynamic calibration is crucial for ensuring your equipment maintains precision during fluctuating operational scenarios.

Key Differences Between Static and Dynamic Calibration

Static calibration measures sensor accuracy under stable, unchanging conditions, ensuring precise baseline readings while dynamic calibration assesses sensor performance during actual, varying operational states to replicate real-world scenarios. Key differences include static calibration's focus on fixed reference points and predictable environments, whereas dynamic calibration evaluates response times, transient behaviors, and sensor reliability under fluctuating pressures or temperatures. Your choice between static and dynamic calibration depends on whether consistent baseline accuracy or real-time performance validation is critical for your application.

Advantages of Static Calibration

Static calibration offers high precision by eliminating variables such as movement or external vibrations, ensuring consistent and reliable sensor measurements. It allows for thorough assessment under controlled conditions, which improves accuracy and repeatability of results. Your calibration process benefits from enhanced stability and ease of setup, leading to reduced measurement uncertainty.

Advantages of Dynamic Calibration

Dynamic calibration offers superior accuracy by evaluating sensor performance under real operational conditions, capturing transient responses and environmental influences that static calibration cannot. It enables continuous monitoring and adjustment, ensuring sustained precision and reliability in dynamic systems such as accelerometers, gyroscopes, and flow meters. This process reduces calibration errors caused by time-dependent variations, leading to improved device functionality and longer service life.

Limitations of Static Calibration

Static calibration involves measuring sensor outputs under fixed, controlled conditions, which limits its accuracy when applied to dynamic environments where variables change rapidly. This method often fails to account for real-time factors such as temperature fluctuations, vibration, and motion-induced errors, leading to potential inaccuracies in sensor data during operation. As a result, static calibration is less effective for applications requiring high precision in variable and dynamic conditions, necessitating dynamic calibration techniques that adapt to changing parameters.

Limitations of Dynamic Calibration

Dynamic calibration, despite its ability to measure sensor performance under varying conditions, faces limitations such as increased complexity and higher costs compared to static calibration. It often requires sophisticated equipment and precise control of variables like motion, temperature, and acceleration, which can introduce measurement errors or inconsistencies. The time-consuming nature and difficulty in replicating real-world dynamic environments further constrain its practical application in routine sensor validation.

Choosing the Right Calibration Method

Choosing the right calibration method depends on your specific application and measurement requirements. Static calibration involves assessing sensor accuracy under controlled, unchanging conditions, ideal for environments with steady parameters. Dynamic calibration evaluates sensor performance under varying conditions, providing more accurate data for applications involving motion, changing temperatures, or fluctuating pressures.

Applications in Industry and Future Trends

Static calibration is widely used in industries like manufacturing and aerospace for ensuring sensor accuracy during equipment setup and routine maintenance, providing consistent measurement references under stationary conditions. Dynamic calibration, essential in automotive testing and robotics, evaluates sensor performance under varying operating conditions to capture real-time data accuracy and system responsiveness. Future trends indicate a growing integration of machine learning algorithms and IoT-enabled devices to enhance both static and dynamic calibration processes, improving precision and enabling predictive maintenance in complex industrial systems.

Static Calibration vs Dynamic Calibration Infographic

libmatt.com

libmatt.com