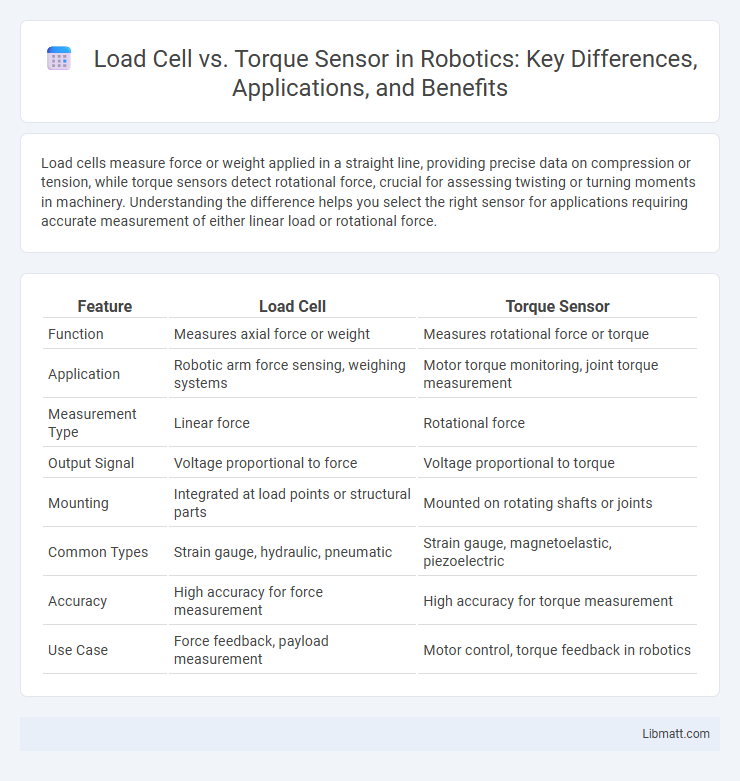

Load cells measure force or weight applied in a straight line, providing precise data on compression or tension, while torque sensors detect rotational force, crucial for assessing twisting or turning moments in machinery. Understanding the difference helps you select the right sensor for applications requiring accurate measurement of either linear load or rotational force.

Table of Comparison

| Feature | Load Cell | Torque Sensor |

|---|---|---|

| Function | Measures axial force or weight | Measures rotational force or torque |

| Application | Robotic arm force sensing, weighing systems | Motor torque monitoring, joint torque measurement |

| Measurement Type | Linear force | Rotational force |

| Output Signal | Voltage proportional to force | Voltage proportional to torque |

| Mounting | Integrated at load points or structural parts | Mounted on rotating shafts or joints |

| Common Types | Strain gauge, hydraulic, pneumatic | Strain gauge, magnetoelastic, piezoelectric |

| Accuracy | High accuracy for force measurement | High accuracy for torque measurement |

| Use Case | Force feedback, payload measurement | Motor control, torque feedback in robotics |

Understanding Load Cells: Definition and Function

Load cells are precise transducers designed to measure force or weight by converting mechanical load into an electrical signal, crucial for accurate measurement in various industrial applications. Unlike torque sensors that measure rotational force or torque, load cells primarily quantify static or dynamic loads in tension, compression, or shear modes. You rely on load cells for precise force measurement in systems requiring high accuracy, calibration, and reliability.

What is a Torque Sensor? Key Concepts Explained

A torque sensor measures the rotational force applied to an object, converting mechanical torque into an electrical signal for precise monitoring and control. Key concepts include strain gauges that detect deformation, calibration for accurate torque measurement, and real-time feedback crucial for applications in automotive, robotics, and industrial machinery. Unlike load cells that measure linear force, torque sensors specifically quantify twisting force, enabling better performance and safety in rotating systems.

Core Differences Between Load Cells and Torque Sensors

Load cells measure linear force or weight by converting mechanical force into an electrical signal, primarily used in applications such as weighing scales and structural testing. Torque sensors detect rotational force or torque applied to a shaft, enabling precise monitoring in machinery like motors and automotive systems. Understanding these core differences helps you select the right sensor based on whether your application requires measurement of linear load or rotational torque.

Types of Load Cells and Their Applications

Strain gauge load cells, one of the most common types, measure force through the deformation of strain gauges attached to a metal element, widely used in weighing scales and industrial measurement. Capacitive load cells utilize changes in electrical capacitance to detect force, often applied in precision force measurement and material testing. Hydraulic load cells convert force into hydraulic pressure, making them suitable for heavy load applications such as structural testing and large-scale industrial machinery.

Types of Torque Sensors and Their Uses

Torque sensors include strain gauge, magnetoelastic, and piezoelectric types, each measuring torque through distinct physical principles. Strain gauge torque sensors are widely used for precision measurement in automotive and industrial applications, while magnetoelastic sensors excel in harsh environments with high durability. Piezoelectric torque sensors provide dynamic torque data in rotating machinery, benefiting aerospace and manufacturing process control.

Key Parameters: Force vs. Torque Measurement

Load cells measure force by converting mechanical load into an electrical signal, providing precise data on linear force or weight applied along a specific axis. Torque sensors, on the other hand, quantify rotational force or torque exerted on a shaft, capturing torsional strain for applications involving twisting motion. Understanding whether your application requires force or torque measurement is crucial for selecting the appropriate sensor to ensure accurate and reliable performance.

Accuracy and Sensitivity: Load Cell vs Torque Sensor

Load cells typically offer high accuracy and sensitivity in measuring linear force, with precision often reaching up to 0.01% of full scale, making them ideal for applications requiring exact weight or force measurement. Torque sensors, while also providing precise measurements, excel in detecting rotational force with sensitivity tailored to twisting or torque loads, generally achieving accuracy levels around 0.1% to 0.5% of full scale. The choice between load cell and torque sensor depends on whether the application demands linear force accuracy or rotational force sensitivity.

Installation and Integration Considerations

Load cells require careful alignment and rigid mounting to ensure accurate force measurement, often necessitating specialized fixtures and calibration to compensate for mechanical stresses. Torque sensors typically demand integration with rotating shafts or couplings, making shaft alignment and vibration isolation critical to maintain precision and prevent sensor damage. Both sensors benefit from compatible signal conditioning electronics and robust wiring to support reliable data acquisition in complex automation systems.

Industry Applications: Choosing the Right Sensor

Load cells are widely used in industries requiring precise weight measurement, such as manufacturing, packaging, and material testing, ensuring accurate force data for quality control and automation. Torque sensors find application in automotive testing, robotics, and motor control, where measuring rotational force is essential for performance optimization and safety. Selecting the right sensor depends on whether the application demands measurement of linear force or rotational force, with load cells suited for weight and tension metrics, and torque sensors tailored for monitoring torque and twisting forces in dynamic systems.

Cost and Maintenance: Which Sensor is More Economical?

Load cells generally offer a more economical solution compared to torque sensors due to their simpler design and widespread availability, resulting in lower initial costs. Maintenance for load cells is typically less intensive, as they have fewer moving parts and are less prone to wear, reducing long-term expenses. Your choice should consider the specific application requirements, but for cost efficiency and minimal upkeep, load cells often present a more budget-friendly option.

Load Cell vs Torque Sensor Infographic

libmatt.com

libmatt.com