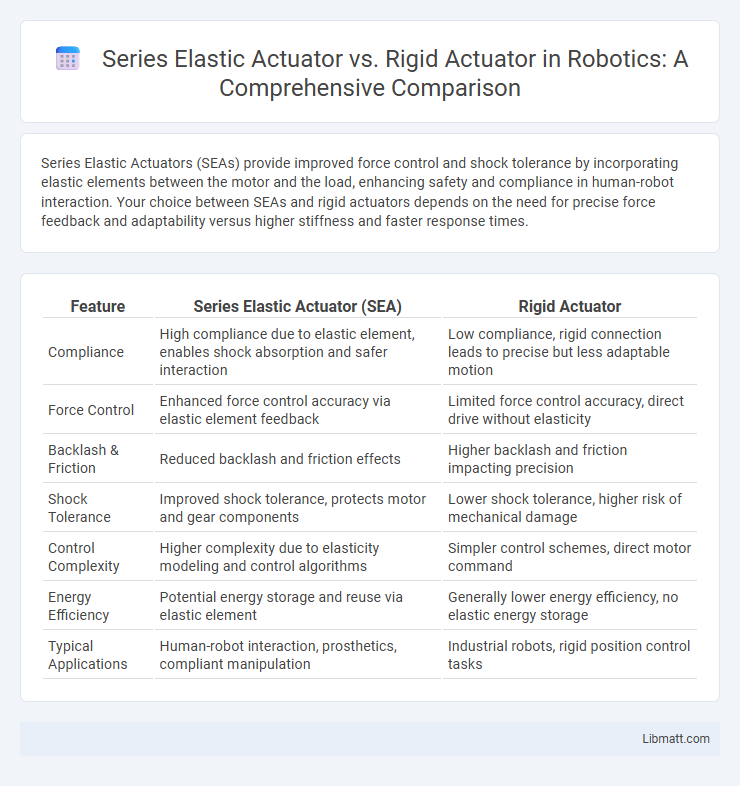

Series Elastic Actuators (SEAs) provide improved force control and shock tolerance by incorporating elastic elements between the motor and the load, enhancing safety and compliance in human-robot interaction. Your choice between SEAs and rigid actuators depends on the need for precise force feedback and adaptability versus higher stiffness and faster response times.

Table of Comparison

| Feature | Series Elastic Actuator (SEA) | Rigid Actuator |

|---|---|---|

| Compliance | High compliance due to elastic element, enables shock absorption and safer interaction | Low compliance, rigid connection leads to precise but less adaptable motion |

| Force Control | Enhanced force control accuracy via elastic element feedback | Limited force control accuracy, direct drive without elasticity |

| Backlash & Friction | Reduced backlash and friction effects | Higher backlash and friction impacting precision |

| Shock Tolerance | Improved shock tolerance, protects motor and gear components | Lower shock tolerance, higher risk of mechanical damage |

| Control Complexity | Higher complexity due to elasticity modeling and control algorithms | Simpler control schemes, direct motor command |

| Energy Efficiency | Potential energy storage and reuse via elastic element | Generally lower energy efficiency, no elastic energy storage |

| Typical Applications | Human-robot interaction, prosthetics, compliant manipulation | Industrial robots, rigid position control tasks |

Introduction to Actuators

Series Elastic Actuators (SEAs) integrate elastic components between the motor and load, improving force control and shock tolerance compared to Rigid Actuators, which connect the motor directly to the load. SEAs offer enhanced compliance and safer human-robot interaction due to their ability to absorb impact and provide precise force feedback. Understanding these differences helps you choose the right actuator type for applications requiring both power and sensitivity.

What are Series Elastic Actuators (SEAs)?

Series Elastic Actuators (SEAs) incorporate elastic elements between the motor and the load, enabling improved force control and shock tolerance compared to rigid actuators. This design allows SEAs to store and release energy, making them ideal for applications requiring compliant interaction and safer human-robot collaboration. Your systems can benefit from SEAs through enhanced precision, reduced impact forces, and increased robustness in dynamic environments.

What are Rigid Actuators?

Rigid actuators are mechanical devices that convert electrical energy into precise, forceful motion without any elastic components between the motor and the load. These actuators provide high stiffness and accurate position control, making them ideal for applications requiring exact movements and minimal compliance. Commonly used in industrial automation, rigid actuators excel in tasks where stability and rigidity are critical to performance.

Key Differences Between SEAs and Rigid Actuators

Series Elastic Actuators (SEAs) incorporate an elastic element between the motor and load, enabling improved force control, shock tolerance, and energy efficiency compared to Rigid Actuators, which directly connect the motor to the load. The compliance in SEAs allows for safer interaction in human-robot collaboration by absorbing impacts and reducing peak forces, whereas Rigid Actuators offer higher precision and stiffness but lack adaptability to dynamic environments. SEAs excel in applications requiring torque control and impact mitigation, while Rigid Actuators dominate where precision and response speed are critical.

Performance Comparison: Force Control and Precision

Series Elastic Actuators (SEAs) provide superior force control and precision by incorporating a compliant element that absorbs shocks and enables accurate force measurement through deflection, enhancing stability in dynamic environments. Rigid actuators, lacking inherent compliance, deliver high stiffness and faster response times but often suffer from force overshoot and reduced precision in delicate tasks due to limited force feedback accuracy. In robotics and prosthetics, SEAs outperform rigid actuators in applications requiring smooth force modulation and precise interaction with unpredictable loads.

Safety and Compliance in Robotics

Series Elastic Actuators (SEAs) enhance safety and compliance in robotics by integrating elastic elements that absorb shocks and reduce impact forces during interactions, minimizing risk to both humans and delicate objects. Rigid actuators lack this inherent flexibility, often resulting in higher stiffness and increased potential for damage or injury during unexpected collisions. Your choice of SEA technology ensures smoother, safer robot behavior in applications requiring sensitive force control and adaptive compliance.

Energy Efficiency and Power Consumption

Series elastic actuators (SEAs) offer improved energy efficiency over rigid actuators by storing and releasing elastic energy during cyclic motions, reducing the net power required from the motor. The compliant element in SEAs absorbs shocks and smooths force transmission, decreasing peak power consumption and enabling more effective energy regeneration in robotic applications. Rigid actuators, lacking such elasticity, typically consume more power due to continuous motor effort to manage load variations and absorb impacts directly.

Application Areas: Industry Use Cases

Series Elastic Actuators (SEAs) excel in collaborative robotics, prosthetics, and rehabilitation devices due to their inherent compliance and shock absorption, enhancing safety and control in human-robot interaction. Rigid Actuators dominate in high-precision industrial automation, CNC machinery, and automotive manufacturing where stiffness and rapid response times are critical for performance and accuracy. Industry use cases for SEAs emphasize adaptability in variable loads, while rigid actuators are preferred for tasks demanding consistent force output and minimal deflection.

Challenges and Limitations

Series Elastic Actuators (SEAs) face challenges such as limited bandwidth and lower force control precision compared to Rigid Actuators, which can restrict their performance in high-speed, high-precision tasks. Rigid Actuators often struggle with impact absorption and compliance, leading to increased wear and potential damage during dynamic interactions. Your choice depends on balancing the need for force control accuracy, mechanical compliance, and responsiveness in the intended application.

Choosing the Right Actuator for Your Needs

Series Elastic Actuators (SEAs) provide enhanced force control and shock absorption by integrating elastic elements, making them ideal for applications requiring precise interaction and safety, such as robotics and prosthetics. Rigid actuators offer higher stiffness and faster response times, better suited for tasks demanding high accuracy and speed without the need for compliance. Selecting the right actuator depends on factors like desired force sensitivity, load variability, and environmental interaction to optimize performance and durability.

Series Elastic Actuator vs Rigid Actuator Infographic

libmatt.com

libmatt.com