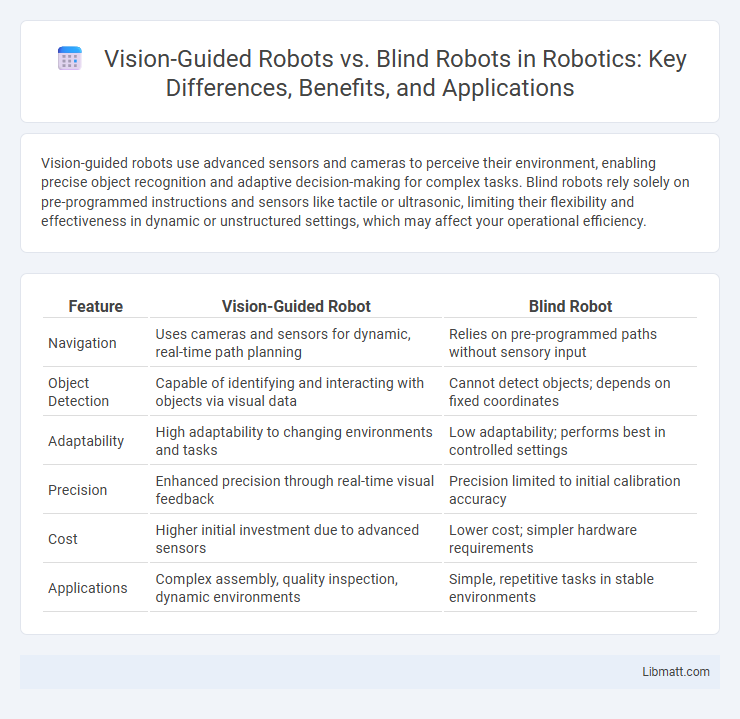

Vision-guided robots use advanced sensors and cameras to perceive their environment, enabling precise object recognition and adaptive decision-making for complex tasks. Blind robots rely solely on pre-programmed instructions and sensors like tactile or ultrasonic, limiting their flexibility and effectiveness in dynamic or unstructured settings, which may affect your operational efficiency.

Table of Comparison

| Feature | Vision-Guided Robot | Blind Robot |

|---|---|---|

| Navigation | Uses cameras and sensors for dynamic, real-time path planning | Relies on pre-programmed paths without sensory input |

| Object Detection | Capable of identifying and interacting with objects via visual data | Cannot detect objects; depends on fixed coordinates |

| Adaptability | High adaptability to changing environments and tasks | Low adaptability; performs best in controlled settings |

| Precision | Enhanced precision through real-time visual feedback | Precision limited to initial calibration accuracy |

| Cost | Higher initial investment due to advanced sensors | Lower cost; simpler hardware requirements |

| Applications | Complex assembly, quality inspection, dynamic environments | Simple, repetitive tasks in stable environments |

Introduction to Vision-Guided Robots and Blind Robots

Vision-guided robots utilize advanced camera systems and image processing algorithms to perceive their environment, enabling precise object recognition and adaptive task execution. In contrast, blind robots operate without visual sensors, relying solely on predefined programming and sensor inputs such as tactile or proximity sensors for navigation and manipulation. The integration of vision systems in robots significantly enhances flexibility, accuracy, and autonomy compared to their blind counterparts.

Core Technologies Behind Each Approach

Vision-guided robots rely on advanced computer vision algorithms, 3D sensors, and machine learning models to interpret visual data for precise manipulation and environment interaction. Blind robots operate primarily through predetermined programming, sensor fusion such as LIDAR or tactile feedback, and motion control systems without real-time visual input. The core technology difference lies in the visual data processing capabilities for dynamic adaptation versus static, sensor-based automation frameworks.

Key Differences in Sensing Capabilities

Vision-guided robots utilize advanced cameras and image processing algorithms to perceive and interpret their environment in real-time, enabling precise object recognition and adaptive responses. Blind robots rely solely on pre-programmed movements or simple sensors, such as proximity or tactile sensors, limiting their ability to adjust to dynamic or complex surroundings. Your choice between these systems depends on the required level of environmental awareness and flexibility in the robotic application.

Applications Suited for Vision-Guided Robots

Vision-guided robots excel in applications requiring precise object recognition, complex assembly tasks, and quality inspection, where real-time image processing enhances accuracy and flexibility. Industries such as electronics manufacturing, automotive assembly, and packaging benefit from these robots by reducing errors and adapting to variable production environments. Your automation processes improve significantly when incorporating vision-guided robots for tasks demanding detailed visual feedback and dynamic decision-making.

Typical Use Cases for Blind Robots

Blind robots excel in repetitive, structured environments such as assembly lines, packaging, and material handling where tasks require high precision without the need for complex visual processing. These robots rely on pre-programmed motions and sensors like force or proximity detectors to perform operations efficiently. Your manufacturing process can benefit from blind robots when tasks involve consistent, predictable actions with minimal variation in the workspace.

Performance and Accuracy Comparison

Vision-guided robots outperform blind robots in complex environments by leveraging real-time visual data, enabling higher precision in object recognition and spatial navigation. The integration of advanced cameras and sensors allows vision-guided systems to adapt dynamically to variable conditions, significantly reducing errors compared to blind robots that rely solely on programmed paths. As a result, vision-guided robots achieve superior accuracy in tasks such as assembly, inspection, and material handling, enhancing overall operational efficiency and productivity.

Cost and Implementation Considerations

Vision-guided robots typically incur higher initial costs due to sophisticated cameras, sensors, and processing units required for real-time image analysis, whereas blind robots rely on simpler, often less expensive sensors such as encoders or proximity detectors. Implementation of vision-guided systems demands extensive calibration, programming, and integration with AI algorithms to interpret visual data effectively, while blind robots offer quicker deployment with more straightforward control systems. Your choice between the two should consider budget constraints alongside the complexity of tasks, as vision-guided robots excel in environments needing precision and adaptability, justifying the higher investment.

Flexibility and Adaptability in Dynamic Environments

Vision-guided robots excel in flexibility and adaptability within dynamic environments by utilizing real-time image processing to detect and respond to changes, enabling precise handling of varying objects and scenarios. Blind robots, relying solely on pre-programmed instructions and sensor data without visual input, lack the capability to adjust to unforeseen obstacles or variations, limiting their performance in complex, rapidly changing settings. The integration of vision systems significantly enhances robotic autonomy and operational efficiency in industries requiring dynamic interaction and quick reconfiguration.

Safety and Error Handling Mechanisms

Vision-guided robots utilize advanced sensors and real-time image processing to detect obstacles and adjust movements, significantly enhancing safety compared to blind robots that operate solely on pre-programmed instructions. These robots implement sophisticated error handling mechanisms by identifying discrepancies between expected and actual environments, reducing collision risks. Blind robots lack this adaptive capability, making them more prone to errors and unsafe interactions in dynamic settings.

Future Trends and Innovations in Robot Guidance Systems

Vision-guided robots are rapidly advancing with innovations in AI-powered image processing and 3D scene reconstruction, enabling enhanced precision and adaptability in complex environments compared to blind robots. Future trends emphasize integration of deep learning algorithms and sensor fusion to improve real-time decision-making and obstacle avoidance. These enhancements position vision-guided systems as critical components in smart manufacturing, autonomous navigation, and collaborative robotics.

Vision-Guided Robot vs Blind Robot Infographic

libmatt.com

libmatt.com