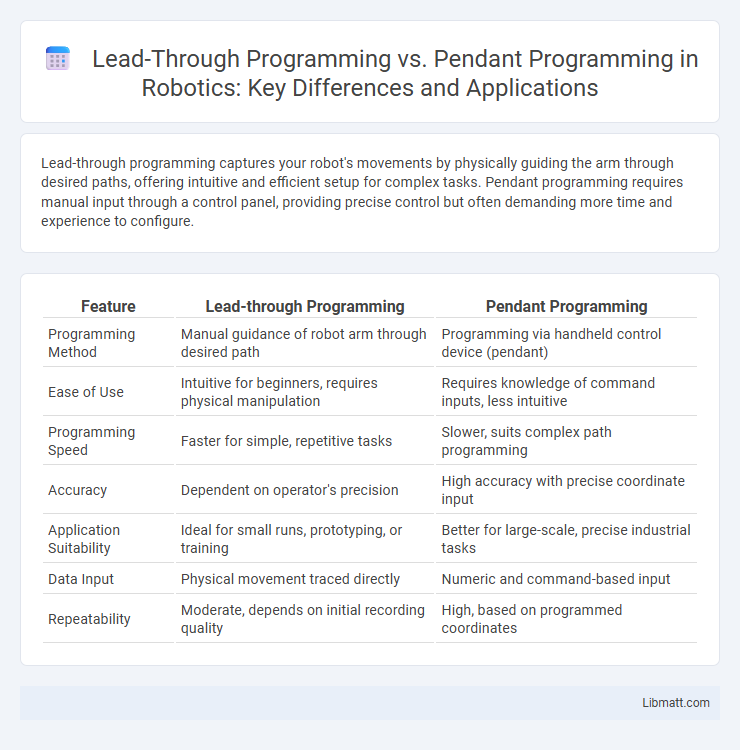

Lead-through programming captures your robot's movements by physically guiding the arm through desired paths, offering intuitive and efficient setup for complex tasks. Pendant programming requires manual input through a control panel, providing precise control but often demanding more time and experience to configure.

Table of Comparison

| Feature | Lead-through Programming | Pendant Programming |

|---|---|---|

| Programming Method | Manual guidance of robot arm through desired path | Programming via handheld control device (pendant) |

| Ease of Use | Intuitive for beginners, requires physical manipulation | Requires knowledge of command inputs, less intuitive |

| Programming Speed | Faster for simple, repetitive tasks | Slower, suits complex path programming |

| Accuracy | Dependent on operator's precision | High accuracy with precise coordinate input |

| Application Suitability | Ideal for small runs, prototyping, or training | Better for large-scale, precise industrial tasks |

| Data Input | Physical movement traced directly | Numeric and command-based input |

| Repeatability | Moderate, depends on initial recording quality | High, based on programmed coordinates |

Introduction to Robot Programming Methods

Lead-through programming enables users to guide robots manually along desired paths, capturing motion data for replication, ideal for intuitive and direct task teaching without coding expertise. Pendant programming involves using a handheld device with a user interface to input commands, allowing precise and detailed control over robot movements and operations through menu-driven or coded instructions. Both methods cater to different skill levels and application requirements, with lead-through being favored for simplicity and pendant programming for flexibility and complexity.

What is Lead-through Programming?

Lead-through programming is a method where the operator physically guides the robot through the desired motion paths, allowing the system to record these movements directly. This intuitive approach eliminates complex code writing, making it ideal for custom or low-volume manufacturing tasks. Your ability to teach the robot by demonstration significantly reduces programming time and simplifies processes compared to traditional pendant programming.

Understanding Pendant Programming

Pendant programming allows you to control and program industrial robots directly using a handheld device called a pendant. This method offers intuitive, real-time manipulation of the robot's movements, making it ideal for precise adjustments and on-the-spot programming. Understanding pendant programming helps optimize your robot's performance by simplifying the programming process and enabling immediate feedback during operation.

Key Differences Between Lead-through and Pendant Programming

Lead-through programming captures robotic motions by physically guiding the robot arm through desired paths, creating intuitive, real-time path data ideal for complex or custom tasks. Pendant programming utilizes a handheld controller, allowing operators to input commands and sequences manually, suited for repetitive or predefined tasks with greater precision. Key differences include real-time motion capture versus manual input, ease of teaching complex paths versus step-by-step control, and flexibility in adaptive workpieces compared to reliance on fixed programs.

Advantages of Lead-through Programming

Lead-through programming offers the advantage of intuitive and efficient robot teaching by physically guiding the robot through desired motions, significantly reducing programming time compared to manual code entry. This method enables precise capturing of complex paths and movements, which enhances accuracy and repeatability in automation tasks. Your workflow benefits from simplified adjustments and quicker optimization, making it ideal for applications requiring flexible and rapid setup.

Benefits of Pendant Programming

Pendant programming offers precise manual control, making it ideal for on-site adjustments and troubleshooting in robotic operations. It enables real-time input and modification of robot paths, enhancing flexibility and reducing downtime during production changes. Your ability to directly interact with the robot's movements improves accuracy and speeds up programming compared to lead-through methods.

Limitations of Lead-through Programming

Lead-through programming is limited by its dependency on physical teaching devices, which restricts the complexity and precision of programmed tasks. It often lacks the flexibility to easily modify or optimize programs without repeating the manual guidance process, making it inefficient for intricate or high-precision manufacturing. Your automation efforts may face challenges in scalability and adaptability due to these inherent constraints of lead-through programming compared to pendant programming.

Drawbacks of Pendant Programming

Pendant programming often suffers from inefficiency due to manual operation, leading to slower programming cycles compared to automated methods like lead-through programming. It requires constant human intervention, increasing the risk of errors and inconsistencies in the robot's movements. Limited precision and repetitive strain on operators further reduce overall productivity in pendant programming environments.

Choosing the Right Programming Method for Your Application

Selecting the optimal programming method depends on your application's complexity and operational environment. Lead-through programming excels in tasks requiring intuitive, hands-on guidance, enabling rapid setup without extensive coding knowledge, while pendant programming offers precise control and flexibility for intricate, repetitive processes through manual input on device interfaces. Evaluating factors such as task complexity, operator expertise, and desired programming speed ensures you choose the method that maximizes efficiency and accuracy for your specific automation needs.

Future Trends in Industrial Robot Programming

Future trends in industrial robot programming emphasize increased adoption of lead-through programming due to its intuitive interface and real-time motion capture capabilities that reduce setup time and improve accuracy. Pendant programming remains relevant for complex, highly customized tasks but is gradually augmented by AI-driven automation and cloud-based collaborative platforms enhancing flexibility and scalability. Integration of digital twins and augmented reality tools streamlines programming workflows, driving a shift toward more adaptive and user-friendly industrial robot management systems.

Lead-through Programming vs Pendant Programming Infographic

libmatt.com

libmatt.com