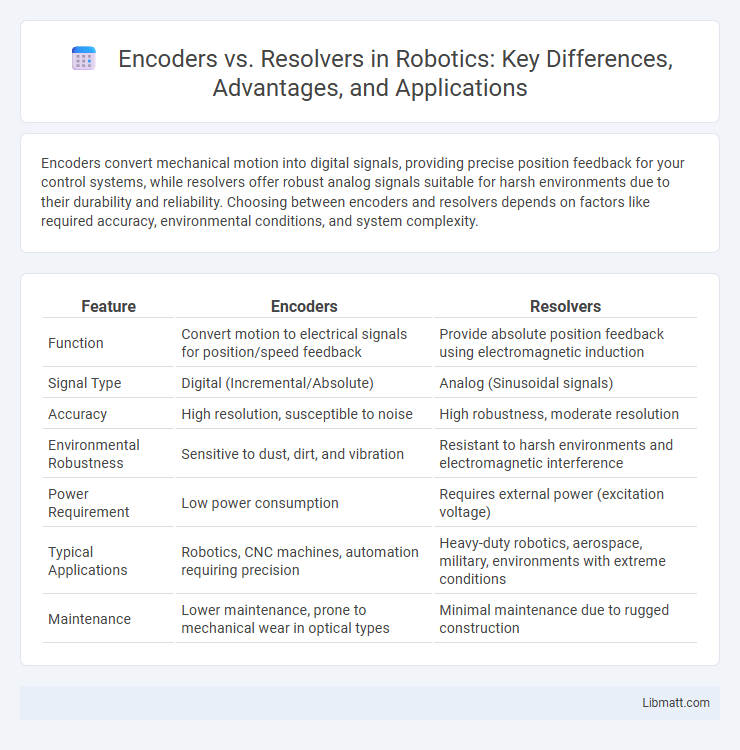

Encoders convert mechanical motion into digital signals, providing precise position feedback for your control systems, while resolvers offer robust analog signals suitable for harsh environments due to their durability and reliability. Choosing between encoders and resolvers depends on factors like required accuracy, environmental conditions, and system complexity.

Table of Comparison

| Feature | Encoders | Resolvers |

|---|---|---|

| Function | Convert motion to electrical signals for position/speed feedback | Provide absolute position feedback using electromagnetic induction |

| Signal Type | Digital (Incremental/Absolute) | Analog (Sinusoidal signals) |

| Accuracy | High resolution, susceptible to noise | High robustness, moderate resolution |

| Environmental Robustness | Sensitive to dust, dirt, and vibration | Resistant to harsh environments and electromagnetic interference |

| Power Requirement | Low power consumption | Requires external power (excitation voltage) |

| Typical Applications | Robotics, CNC machines, automation requiring precision | Heavy-duty robotics, aerospace, military, environments with extreme conditions |

| Maintenance | Lower maintenance, prone to mechanical wear in optical types | Minimal maintenance due to rugged construction |

Introduction to Position Sensors

Position sensors like encoders and resolvers play a critical role in detecting the angular or linear position of a shaft or object in various industrial applications. Encoders provide digital output signals for precise position feedback, commonly used in robotics and CNC machinery, while resolvers offer robust analog signals, making them ideal for harsh environments requiring reliability. Choosing the right sensor depends on your system's accuracy requirements, environmental conditions, and signal processing capabilities.

What Are Encoders?

Encoders are sensors that convert mechanical motion into an electrical signal to provide precise position, speed, or direction feedback in industrial automation. They are commonly used in robotics, CNC machines, and conveyor systems to ensure accurate motion control and synchronization. Optical and magnetic are the two primary types of encoders, each offering distinct advantages based on their sensing method and application requirements.

How Resolvers Work

Resolvers operate by converting mechanical position into electrical signals through electromagnetic induction, utilizing a rotating transformer design with a stationary stator and a rotating rotor. As the rotor turns, it modulates the amplitude of sinusoidal voltages induced in the stator windings, producing sine and cosine output signals that correspond to the angular position. Your control system interprets these signals to determine precise shaft position and speed even in harsh environments with high reliability and noise immunity.

Key Differences Between Encoders and Resolvers

Encoders convert mechanical motion into digital signals for precise position feedback, while resolvers generate analog signals based on rotating magnetic fields to determine angular position. Encoders typically offer higher resolution and are sensitive to environmental factors like dust and vibration, whereas resolvers are robust, operate reliably in harsh conditions, and provide absolute position data without requiring a battery or signal reference. Understanding your application's environmental constraints and accuracy requirements is crucial when choosing between encoders and resolvers.

Applications of Encoders

Encoders are widely used in robotics, industrial automation, and CNC machines to provide precise position and speed feedback for motion control systems. Your choice of an encoder enhances accuracy in applications such as elevator control, conveyor systems, and motor shaft positioning, enabling efficient automation and monitoring. Unlike resolvers, encoders offer digital output signals, making them ideal for integration with modern control electronics and real-time data processing.

Applications of Resolvers

Resolvers are widely used in harsh industrial environments due to their robustness and reliability in measuring angular position and speed, especially in aerospace, military, and automotive applications. Their ability to operate accurately under extreme temperatures, vibrations, and electromagnetic interference makes them ideal for position feedback in servo motors and robotics. Resolvers are also critical in aerospace navigation systems and missile guidance, where precision and durability are paramount.

Accuracy and Resolution Comparison

Encoders generally provide high resolution with precise digital output, making them ideal for applications requiring accurate position feedback. Resolvers offer robust performance in harsh environments but typically have lower resolution and accuracy compared to optical encoders. Your choice depends on whether you prioritize environmental durability or the highest positional precision.

Environmental Suitability: Harsh and Industrial Environments

Encoders and resolvers differ significantly in environmental suitability, especially in harsh and industrial environments. Resolvers excel due to their rugged construction, resistance to extreme temperatures, vibrations, and electromagnetic interference, making them ideal for heavy-duty machinery. You should consider resolvers over encoders for applications where durability and reliability under severe conditions are critical.

Cost and Maintenance Considerations

Encoders generally offer a lower initial cost compared to resolvers, making them a cost-effective choice for many applications. You should consider that encoders tend to require more frequent maintenance due to their reliance on optical or magnetic components that can wear out over time. In contrast, resolvers provide higher durability with minimal maintenance needs, which can reduce long-term operational expenses despite a higher upfront investment.

Choosing the Right Sensor for Your Application

Encoders provide precise digital position feedback ideal for applications requiring high accuracy and speed, while resolvers excel in harsh environments with robust analog signals resistant to electrical noise and extreme temperatures. Choosing between an encoder and a resolver depends on factors such as resolution needs, environmental conditions, and system complexity to ensure optimal performance and reliability. Your application benefits most when the sensor aligns with operational demands, balancing accuracy, durability, and cost-effectiveness.

Encoders vs Resolvers Infographic

libmatt.com

libmatt.com