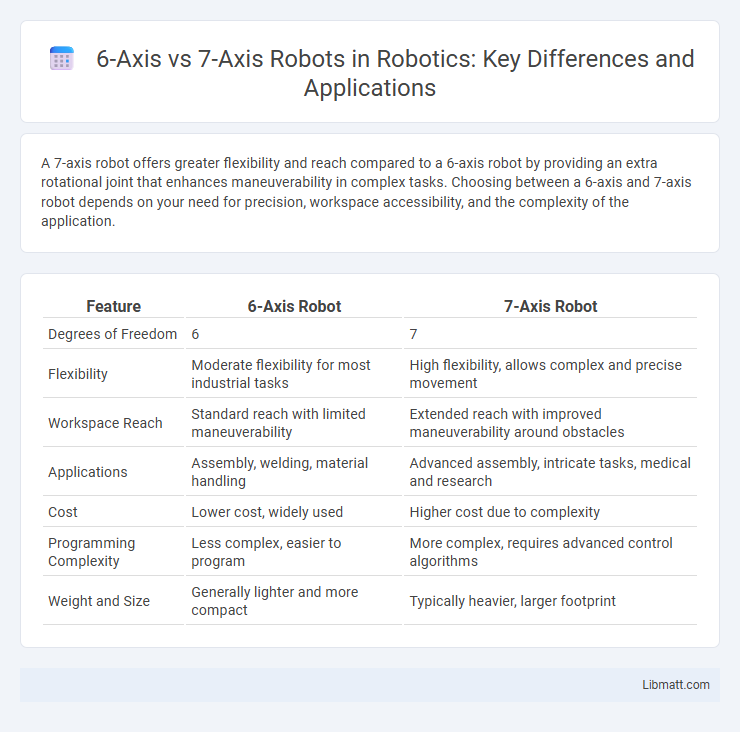

A 7-axis robot offers greater flexibility and reach compared to a 6-axis robot by providing an extra rotational joint that enhances maneuverability in complex tasks. Choosing between a 6-axis and 7-axis robot depends on your need for precision, workspace accessibility, and the complexity of the application.

Table of Comparison

| Feature | 6-Axis Robot | 7-Axis Robot |

|---|---|---|

| Degrees of Freedom | 6 | 7 |

| Flexibility | Moderate flexibility for most industrial tasks | High flexibility, allows complex and precise movement |

| Workspace Reach | Standard reach with limited maneuverability | Extended reach with improved maneuverability around obstacles |

| Applications | Assembly, welding, material handling | Advanced assembly, intricate tasks, medical and research |

| Cost | Lower cost, widely used | Higher cost due to complexity |

| Programming Complexity | Less complex, easier to program | More complex, requires advanced control algorithms |

| Weight and Size | Generally lighter and more compact | Typically heavier, larger footprint |

Introduction to 6-Axis and 7-Axis Robots

6-axis robots feature six degrees of freedom, allowing versatile movement suitable for tasks like welding, assembly, and material handling, while 7-axis robots add an extra degree of freedom for enhanced flexibility and reach in complex environments. The additional seventh axis enables optimized maneuverability around obstacles, making them ideal for intricate applications in aerospace, automotive, and medical industries. Both robot types improve automation efficiency but differ primarily in their range of motion and adaptability to task-specific requirements.

Core Differences Between 6-Axis and 7-Axis Robots

6-axis robots provide six degrees of freedom, enabling flexible movement in most manufacturing tasks including welding, painting, and assembly with a fixed range of motion. 7-axis robots add an extra degree of freedom, allowing enhanced maneuverability and the ability to reach around obstacles or work in confined spaces with greater precision. This additional axis improves versatility and human-like motion, making 7-axis robots suitable for complex tasks in aerospace, medical device assembly, and intricate automation environments.

Applications of 6-Axis Robots in Industry

6-axis robots are extensively used in industrial applications such as welding, material handling, assembly, machine tending, and packaging due to their versatile movement and ability to reach complex positions. Their six degrees of freedom support precise tasks like painting automotive parts, performing high-speed pick-and-place operations, and executing intricate machining processes. These robots enhance efficiency and accuracy in manufacturing environments where flexibility and repeatability are essential.

Advantages of 7-Axis Robotics Technology

7-axis robotics technology offers enhanced flexibility and reach compared to traditional 6-axis robots, allowing for more complex and precise movements in confined spaces. The additional rotational axis provides improved maneuverability, enabling robots to perform tasks with greater dexterity and reduced collision risk. This increased range of motion supports advanced applications such as intricate assembly, welding, and material handling in industries like automotive and aerospace.

Flexibility and Reach: Comparing Movement Capabilities

A 7-axis robot offers enhanced flexibility compared to a 6-axis robot by providing an additional degree of freedom, allowing more complex and precise movements in confined spaces. Your operations benefit from improved reach and maneuverability, enabling the robot to access difficult angles and optimize task performance. This extra axis also reduces joint singularity issues, increasing the robot's overall adaptability in dynamic manufacturing environments.

Workspace Efficiency: 6-Axis vs 7-Axis Robots

A 7-axis robot offers greater workspace efficiency compared to a 6-axis robot due to its extra degree of freedom, allowing it to reach around obstacles and access complex angles with ease. This additional axis enhances maneuverability and flexibility, making it ideal for tasks requiring intricate movements and improved positioning accuracy. Optimizing your operations with a 7-axis robot can lead to better space utilization and higher productivity in confined or complicated work environments.

Programming and Integration Challenges

Programming 6-axis robots involves relatively straightforward motion control with fewer degrees of freedom, simplifying path planning and collision avoidance in structured environments. In contrast, 7-axis robots demand complex kinematic algorithms to manage an extra rotational joint, increasing computational load and requiring advanced programming techniques for smooth integration. Integration challenges for 7-axis systems include precise calibration and synchronization with other equipment to fully leverage their enhanced flexibility in confined or intricate workspaces.

Cost Considerations and ROI Analysis

6-axis robots generally offer lower upfront costs and simpler maintenance, making them cost-effective for standard industrial tasks while 7-axis robots command higher prices due to advanced articulation and greater flexibility. The ROI for 7-axis robots improves significantly in complex applications requiring intricate maneuverability and reach, enabling higher productivity and reduced cycle times despite the initial investment. Evaluating task complexity and production volume is essential to determine whether the enhanced capabilities of a 7-axis robot justify the increased cost over a 6-axis option.

Choosing the Right Robot for Your Application

Selecting between a 6-axis and a 7-axis robot depends on the complexity and range of motion required in your application. A 6-axis robot offers precise movement along six degrees of freedom, ideal for standard assembly, welding, and material handling tasks, while a 7-axis robot provides an additional degree of freedom that enables greater flexibility and reach in confined or intricate spaces. Evaluating factors such as workspace constraints, payload capacity, and required dexterity ensures the best robot choice for efficiency and performance in specific industrial applications.

Future Trends in Multi-Axis Robotic Systems

The evolution from 6-axis to 7-axis robotic systems reflects a growing demand for enhanced flexibility and precision in industrial automation. Future trends indicate that 7-axis robots will dominate sectors requiring complex maneuverability and reach, such as aerospace and automotive manufacturing, due to their increased degrees of freedom and improved collision avoidance capabilities. Integration with advanced AI and machine learning algorithms will further optimize multi-axis robotic performance, enabling real-time adaptive control and predictive maintenance.

6-axis vs 7-axis Robot Infographic

libmatt.com

libmatt.com