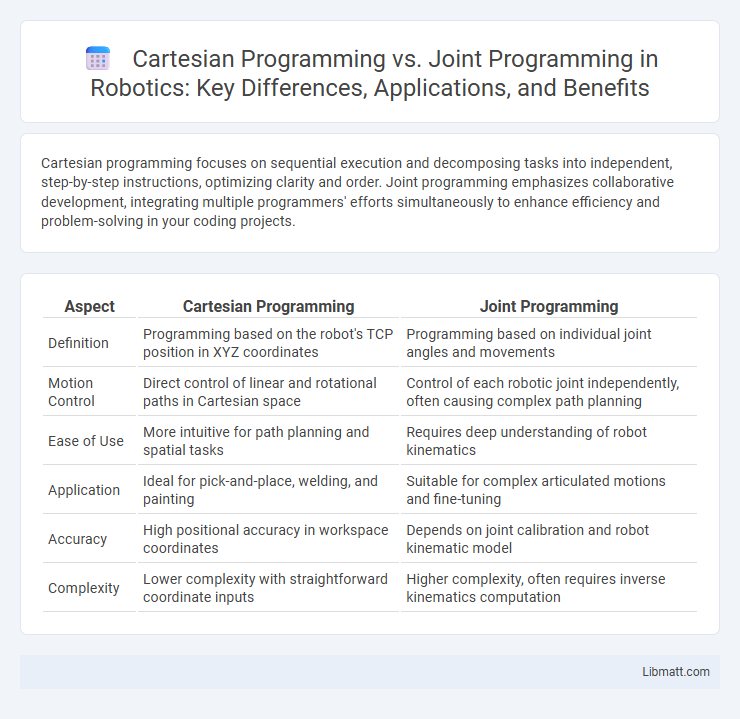

Cartesian programming focuses on sequential execution and decomposing tasks into independent, step-by-step instructions, optimizing clarity and order. Joint programming emphasizes collaborative development, integrating multiple programmers' efforts simultaneously to enhance efficiency and problem-solving in your coding projects.

Table of Comparison

| Aspect | Cartesian Programming | Joint Programming |

|---|---|---|

| Definition | Programming based on the robot's TCP position in XYZ coordinates | Programming based on individual joint angles and movements |

| Motion Control | Direct control of linear and rotational paths in Cartesian space | Control of each robotic joint independently, often causing complex path planning |

| Ease of Use | More intuitive for path planning and spatial tasks | Requires deep understanding of robot kinematics |

| Application | Ideal for pick-and-place, welding, and painting | Suitable for complex articulated motions and fine-tuning |

| Accuracy | High positional accuracy in workspace coordinates | Depends on joint calibration and robot kinematic model |

| Complexity | Lower complexity with straightforward coordinate inputs | Higher complexity, often requires inverse kinematics computation |

Introduction to Cartesian and Joint Programming

Cartesian Programming organizes robotic movements using distinct, linear coordinate axes, enabling precise control of position along X, Y, and Z planes for straightforward tasks. Joint Programming focuses on controlling each robotic joint's angle and rotation, optimizing the robot's posture and flexibility for complex, articulated motions. You can choose between these approaches based on the desired precision and complexity of your robotic applications.

Understanding Cartesian Programming

Cartesian Programming organizes tasks along independent axes, enabling precise control of movements in robotics and CNC machining by manipulating coordinates in a defined X, Y, and Z space. It contrasts with Joint Programming, which focuses on controlling individual joint angles and movements within robotic arms. Understanding Cartesian Programming is essential for applications requiring exact positioning and linear motion paths in automation and manufacturing processes.

Exploring Joint Programming in Robotics

Joint programming in robotics emphasizes coordinated, multi-axis control strategies that enable robots to perform complex tasks with fluid, human-like motion, contrasting with Cartesian programming which relies on predefined linear paths along X, Y, and Z axes. This approach enhances robotic dexterity, allowing simultaneous joint movements that optimize efficiency and precision in applications such as assembly lines and collaborative robots. By integrating inverse kinematics algorithms, joint programming facilitates adaptive responses to dynamic environments, advancing robotic autonomy and versatility.

Key Differences Between Cartesian and Joint Programming

Cartesian programming controls robot motion through linear movements along defined X, Y, and Z axes, prioritizing precise and straightforward path planning ideal for tasks requiring straight-line motions. Joint programming manipulates each robotic joint independently, allowing for complex, curved trajectories and enhanced flexibility in multi-axis robots, suitable for applications demanding intricate maneuvers. The main differences lie in the degrees of freedom control, path smoothness, and the complexity of programming, where Cartesian programming offers simplicity and repeatability, and joint programming provides adaptability and efficiency in complex spatial tasks.

Advantages of Cartesian Programming

Cartesian programming offers precise control over robotic movements using linear coordinates, enhancing accuracy in automated tasks like CNC machining and 3D printing. It simplifies programming and debugging due to its structured XYZ coordinate system, reducing complexity compared to joint programming. The straightforward linear path planning also increases repeatability and efficiency in manufacturing processes.

Benefits of Joint Programming Approaches

Joint Programming approaches enhance collaboration by integrating diverse expertise, leading to more efficient problem-solving and innovation. This method reduces errors and accelerates development cycles through continuous feedback and shared responsibilities. Increased communication and real-time synchronization foster adaptive solutions and higher software quality compared to Cartesian Programming.

Application Areas for Cartesian Programming

Cartesian programming excels in industrial robotics, particularly in automated manufacturing, CNC machining, and 3D printing due to its linear XYZ axis control. Its application areas also extend to pick-and-place systems and robotic assembly lines where precision and repeatability along orthogonal axes are essential. Your automation solutions benefit from Cartesian programming when tasks require straightforward, linear movements optimized for speed and accuracy.

Use Cases for Joint Programming

Joint programming excels in complex, collaborative projects such as autonomous robotics, multi-agent systems, and real-time control applications where coordinated movements or actions of multiple entities are required. It facilitates synchronized decision-making and efficient communication between components, optimizing overall system performance and adaptability in dynamic environments. Industries like aerospace, manufacturing automation, and cooperative robotics leverage joint programming to enhance precision, safety, and operational efficiency.

Challenges and Limitations of Each Method

Cartesian Programming faces challenges in adaptability and flexibility, as its linear step-by-step structure limits handling dynamic or complex movements. Joint Programming struggles with limitations in precision and increased computational demands due to the need for real-time inverse kinematics calculations. Your choice between these methods should consider the trade-offs between control simplicity in Cartesian systems and the nuanced joint coordination required in Joint Programming.

Choosing the Right Programming Method for Your Robot

Choosing the right programming method for your robot depends on the specific application and desired precision. Cartesian programming focuses on defining movements through X, Y, and Z coordinates, making it ideal for tasks requiring straightforward linear paths and repeatability. Joint programming moves the robot by controlling individual joint angles, offering greater flexibility for complex and dynamic operations where precise joint coordination is essential.

Cartesian Programming vs Joint Programming Infographic

libmatt.com

libmatt.com