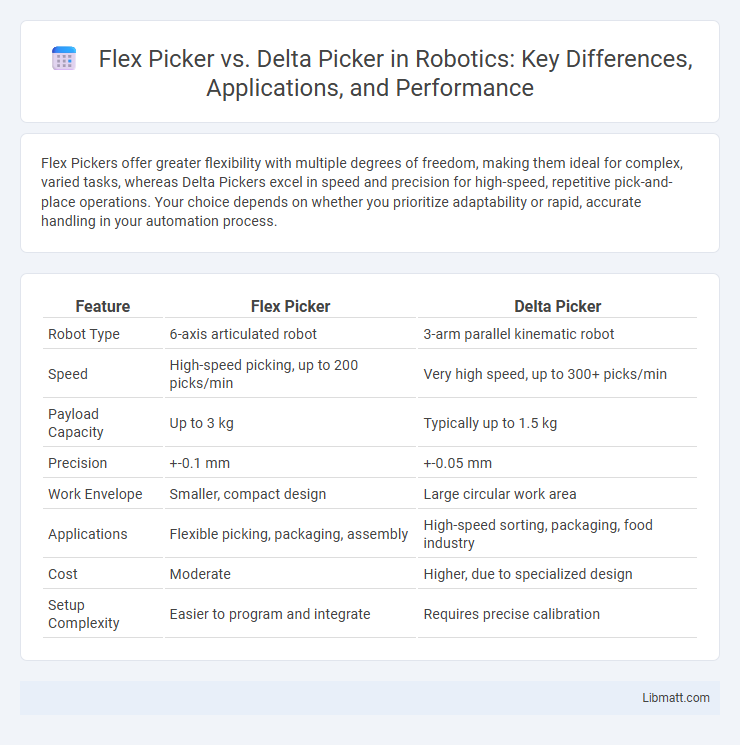

Flex Pickers offer greater flexibility with multiple degrees of freedom, making them ideal for complex, varied tasks, whereas Delta Pickers excel in speed and precision for high-speed, repetitive pick-and-place operations. Your choice depends on whether you prioritize adaptability or rapid, accurate handling in your automation process.

Table of Comparison

| Feature | Flex Picker | Delta Picker |

|---|---|---|

| Robot Type | 6-axis articulated robot | 3-arm parallel kinematic robot |

| Speed | High-speed picking, up to 200 picks/min | Very high speed, up to 300+ picks/min |

| Payload Capacity | Up to 3 kg | Typically up to 1.5 kg |

| Precision | +-0.1 mm | +-0.05 mm |

| Work Envelope | Smaller, compact design | Large circular work area |

| Applications | Flexible picking, packaging, assembly | High-speed sorting, packaging, food industry |

| Cost | Moderate | Higher, due to specialized design |

| Setup Complexity | Easier to program and integrate | Requires precise calibration |

Introduction to Flex Picker and Delta Picker

Flex Picker and Delta Picker are two prominent types of robotic picking systems used in industrial automation, each designed for specific material handling tasks. Flex Pickers utilize a parallel gripper mechanism with high precision and speed, ideal for delicate and consistent item sorting, while Delta Pickers employ a spider-like, delta configuration allowing rapid multi-directional movement perfect for high-speed pick-and-place operations. Both systems enhance efficiency in manufacturing and packaging environments, with their distinct kinematic designs tailored to varying operational needs.

Key Differences Between Flex Picker and Delta Picker

Flex Picker robots excel in high-speed, precise pick-and-place tasks with a compact, lightweight design ideal for small to medium-sized items. Delta Picker robots offer a larger working envelope and greater payload capacity, making them suitable for handling heavier or bulkier products in food, pharmaceutical, and packaging industries. Your choice depends on the specific speed, payload, and workspace requirements of your automation process.

Design and Structural Comparison

The Flex Picker features a lightweight, articulated design ideal for high-speed, precise pick-and-place tasks, emphasizing flexibility with its multiple servo axes. In contrast, the Delta Picker employs a parallel-arm structure with three symmetrical arms connected to a common base, providing exceptional speed and repeatability for handling small components in cleanroom environments. Your choice depends on whether priority is given to adaptable motion and compactness (Flex Picker) or ultra-fast, highly repeatable pick operations (Delta Picker).

Speed and Efficiency Analysis

Flex Pickers offer higher speed and acceleration rates, making them ideal for quick pick-and-place tasks in environments requiring rapid throughput. Delta Pickers excel in efficiency by providing precise three-axis movement with minimal footprint, optimizing space in compact production lines. Your choice depends on whether you prioritize speed with Flex Pickers or spatial efficiency with Delta Pickers for your automation needs.

Applications in Industrial Automation

Flex Pickers excel in high-speed, precise handling of lightweight items in electronics and packaging industries, offering superior flexibility for intricate pick-and-place tasks. Delta Pickers dominate in fast, repetitive operations such as food processing and pharmaceutical assembly, leveraging their parallel kinematic design for rapid three-dimensional motion. Both robots enhance automation efficiency, but Flex Pickers prioritize adaptability while Delta Pickers maximize speed in specific industrial environments.

Payload Capacity and Performance

Flex Pickers typically offer higher payload capacity, reaching up to 10 kg, making them ideal for medium-weight handling tasks in fast-paced environments. Delta Pickers excel in ultra-high-speed performance with payloads usually limited to 1-3 kg, optimized for lightweight, precision sorting and packaging applications. The choice between the two depends on balancing the required payload with speed and operational efficiency in specific industrial processes.

Flexibility and Versatility

Flex Pickers offer exceptional flexibility and versatility with their compact design and multi-axis movement, making them ideal for handling diverse products in fast-paced environments. Delta Pickers excel in high-speed, precise picking tasks within confined spaces, leveraging their lightweight structure and rapid parallel arm motions. Your choice depends on whether your application demands adaptable payload handling (Flex Picker) or ultra-fast, repetitive pick-and-place operations (Delta Picker).

Maintenance and Reliability

The Flex Picker offers lower maintenance requirements due to its simpler design with fewer moving parts, enhancing reliability in high-speed sorting applications. In contrast, the Delta Picker's complex delta robot mechanism demands more frequent maintenance to ensure precision and prevent downtime. Your choice should consider the trade-off between the Flex Picker's ease of upkeep and the Delta Picker's potential for superior accuracy in delicate handling tasks.

Cost and Return on Investment

Flex Picker robotics offer a lower initial purchase price and reduced maintenance costs compared to Delta Picker systems, making them highly accessible for small to medium-sized businesses. While Delta Pickers excel in speed and precision, their higher upfront investment requires a longer payback period, though they deliver superior throughput in high-volume production environments. Companies aiming for rapid ROI often prefer Flex Pickers for moderate automation tasks, whereas enterprises focusing on long-term efficiency and scalability invest in Delta Pickers despite the increased cost.

Choosing the Right Picker for Your Needs

Flex Pickers excel in tasks requiring smooth, precise movement and clean handling of delicate products, making them ideal for food, pharmaceutical, and electronics industries. Delta Pickers offer superior speed and high-throughput capabilities with a compact design, suited for packaging, assembly, and sorting applications demanding rapid, repetitive motion. Selecting the right picker depends on your operational priorities: Flex Pickers prioritize gentle handling and precision, while Delta Pickers maximize speed and efficiency in high-volume workflows.

Flex Picker vs Delta Picker Infographic

libmatt.com

libmatt.com