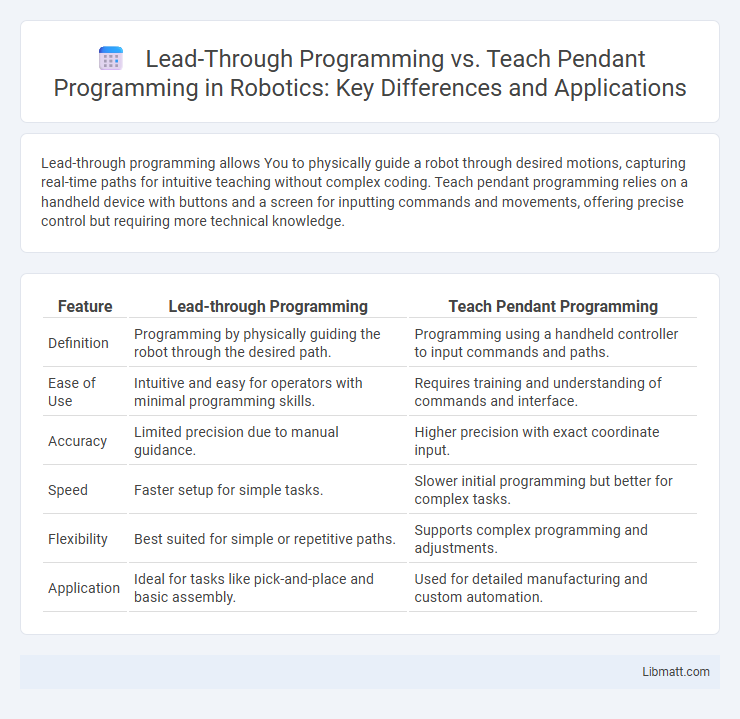

Lead-through programming allows You to physically guide a robot through desired motions, capturing real-time paths for intuitive teaching without complex coding. Teach pendant programming relies on a handheld device with buttons and a screen for inputting commands and movements, offering precise control but requiring more technical knowledge.

Table of Comparison

| Feature | Lead-through Programming | Teach Pendant Programming |

|---|---|---|

| Definition | Programming by physically guiding the robot through the desired path. | Programming using a handheld controller to input commands and paths. |

| Ease of Use | Intuitive and easy for operators with minimal programming skills. | Requires training and understanding of commands and interface. |

| Accuracy | Limited precision due to manual guidance. | Higher precision with exact coordinate input. |

| Speed | Faster setup for simple tasks. | Slower initial programming but better for complex tasks. |

| Flexibility | Best suited for simple or repetitive paths. | Supports complex programming and adjustments. |

| Application | Ideal for tasks like pick-and-place and basic assembly. | Used for detailed manufacturing and custom automation. |

Introduction to Robot Programming Methods

Lead-through programming allows operators to physically guide a robot through desired motions, capturing the path for precise replication, which enhances ease of use and reduces programming time for complex tasks. Teach pendant programming relies on a handheld device to manually input and edit commands, providing detailed control over robot parameters and motion sequences but often requiring more programming expertise. Both methods serve critical roles in industrial automation, with lead-through ideal for flexible, hands-on applications and teach pendant suited for intricate, high-precision operations.

Overview of Lead-through Programming

Lead-through programming offers an intuitive method where operators physically guide a robot through tasks, capturing movements directly for replication. This hands-on approach accelerates programming for complex or customized actions without requiring expert coding skills. It enhances versatility and reduces downtime, making it ideal for dynamic manufacturing environments.

Overview of Teach Pendant Programming

Teach pendant programming enables you to control industrial robots by manually guiding the robot arm through the desired motions using a handheld device. This method facilitates precise path definition and real-time adjustments, making it ideal for complex tasks requiring fine-tuned movements. The teach pendant interface displays real-time feedback, allowing operators to verify and optimize robot trajectories efficiently.

Key Differences Between Lead-through and Teach Pendant Programming

Lead-through programming involves physically guiding a robot through desired motions to record tasks, enabling intuitive path creation without coding, while teach pendant programming uses a handheld device to input commands, parameters, and waypoints manually. Lead-through programming excels in complex path teaching with real-time adjustment, whereas teach pendant programming offers precise control over robot functions, useful for repetitive or pre-defined tasks. The key differences lie in user interaction--direct manipulation versus command entry--and application suitability, where lead-through is ideal for rapid prototyping and teach pendant suits detailed task refinement.

Advantages of Lead-through Programming

Lead-through programming offers significant advantages by allowing you to directly guide robotic arms through desired motions, enabling intuitive and precise path creation without requiring advanced coding skills. This method reduces programming time and minimizes errors by capturing real-time, natural movements, which is particularly beneficial for complex or custom tasks. Its hands-on approach also enhances training efficiency and ease of use, making automation more accessible for operators with diverse expertise.

Advantages of Teach Pendant Programming

Teach Pendant programming offers precise control and real-time feedback, making it easier to fine-tune robotic movements for complex tasks. It allows operators to directly interact with the robot through an intuitive interface, reducing programming time and minimizing errors compared to lead-through programming. Your workflow benefits from enhanced flexibility and improved safety when adjusting parameters on the teach pendant screen.

Limitations and Challenges of Each Method

Lead-through programming faces limitations such as reduced precision for complex tasks and dependency on the operator's manual dexterity, causing variability in repeatability. Teach pendant programming challenges include slower programming speed and steep learning curves, especially for novices, resulting in potential inefficiencies and errors. Both methods encounter difficulties in adapting quickly to dynamic changes in production environments due to their inherent reliance on pre-defined paths and manual interventions.

Application Scenarios and Use Cases

Lead-through programming excels in applications requiring intuitive, hands-on robot guidance, such as small batch production and customized manufacturing where direct operator interaction ensures precision and speed. Teach pendant programming suits complex, repetitive tasks in large-scale industrial environments, offering detailed path control and program editing for processes like automotive assembly or electronics fabrication. Your choice depends on operational complexity and the need for flexibility versus detailed control in robotic workflows.

Factors to Consider When Choosing a Programming Method

Choosing between lead-through programming and teach pendant programming depends on factors such as task complexity, programming speed, and user expertise. Lead-through programming offers intuitive, hands-on control ideal for simple, repetitive tasks and users with limited coding experience. Your selection should balance the need for precision and adaptability with available training and the specific requirements of the robotic application.

Future Trends in Industrial Robot Programming

Future trends in industrial robot programming emphasize increased adoption of lead-through programming due to its intuitive, hands-on approach that reduces setup time and lowers the skill barrier for operators. Teach pendant programming remains relevant for precision tasks but is increasingly integrated with AI-driven simulation tools and augmented reality interfaces to enhance programming accuracy and efficiency. Advances in machine learning and cloud-based collaboration platforms are driving a shift towards hybrid systems that combine the strengths of lead-through and teach pendant methods for flexible, scalable automation.

Lead-through programming vs Teach pendant programming Infographic

libmatt.com

libmatt.com