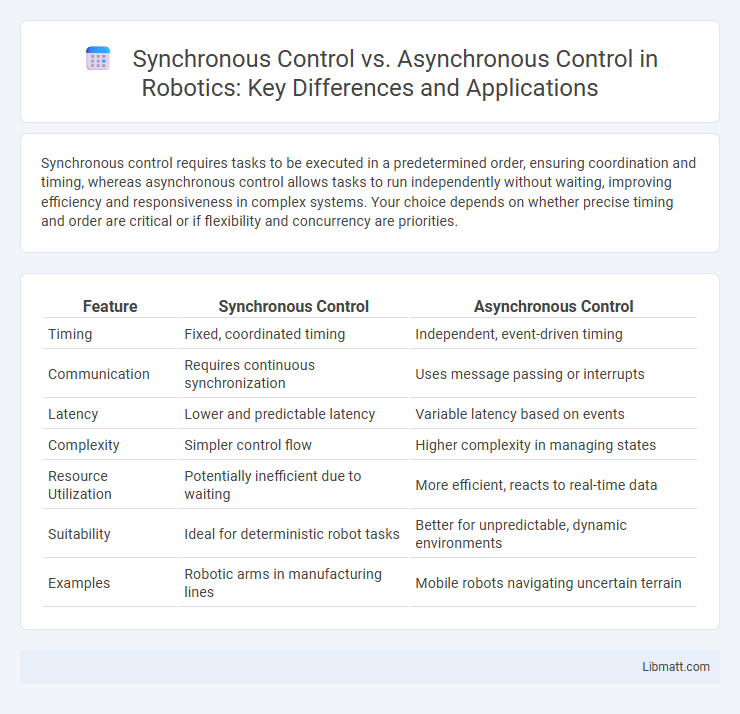

Synchronous control requires tasks to be executed in a predetermined order, ensuring coordination and timing, whereas asynchronous control allows tasks to run independently without waiting, improving efficiency and responsiveness in complex systems. Your choice depends on whether precise timing and order are critical or if flexibility and concurrency are priorities.

Table of Comparison

| Feature | Synchronous Control | Asynchronous Control |

|---|---|---|

| Timing | Fixed, coordinated timing | Independent, event-driven timing |

| Communication | Requires continuous synchronization | Uses message passing or interrupts |

| Latency | Lower and predictable latency | Variable latency based on events |

| Complexity | Simpler control flow | Higher complexity in managing states |

| Resource Utilization | Potentially inefficient due to waiting | More efficient, reacts to real-time data |

| Suitability | Ideal for deterministic robot tasks | Better for unpredictable, dynamic environments |

| Examples | Robotic arms in manufacturing lines | Mobile robots navigating uncertain terrain |

Introduction to Synchronous and Asynchronous Control

Synchronous control systems operate based on a shared clock signal, ensuring coordinated timing and precise execution of tasks across all components. Asynchronous control systems function without a global clock, triggering operations independently based on events or conditions, leading to flexible and efficient handling of processes. Understanding the fundamental differences in timing and coordination mechanisms is critical in designing effective control architectures for various applications in electronics and computing.

Core Concepts: What is Synchronous Control?

Synchronous control refers to a process management method where operations are coordinated to occur at the same time based on a shared clock signal, ensuring tasks execute in a fixed, predictable sequence. This approach relies on synchronization mechanisms to align system components, minimizing timing uncertainties and enabling precise control over data processing and communication. Your system benefits from synchronous control by achieving consistent timing, which is critical for applications requiring accurate coordination and real-time responses.

Understanding Asynchronous Control Mechanisms

Asynchronous control mechanisms operate independently of a global clock, allowing processes to execute at their own pace, which increases system flexibility and responsiveness. Unlike synchronous control that relies on timed coordination, asynchronous control uses handshaking protocols to manage communication and data transfer between components. Understanding these mechanisms helps you optimize system performance in environments where timing variability and low latency are critical.

Key Differences Between Synchronous and Asynchronous Control

Synchronous control requires processes to operate in lockstep, coordinated by a global clock, ensuring predictable timing and order of execution, which is essential for real-time systems. Asynchronous control lets processes run independently without a global clock, allowing flexibility and efficiency in handling tasks with variable execution times but potentially introducing race conditions or timing uncertainties. Understanding these key differences helps you design control systems that balance timing precision and operational flexibility based on your application's requirements.

Advantages of Synchronous Control Systems

Synchronous control systems offer precise timing coordination by ensuring all components operate in unison, which enhances system stability and reduces latency. These systems improve reliability in applications requiring exact synchronization, such as robotics and communication networks. Your processes benefit from increased accuracy and predictability, leading to optimized performance and easier troubleshooting.

Benefits of Asynchronous Control in Modern Applications

Asynchronous control improves responsiveness and efficiency in modern applications by allowing tasks to execute concurrently without waiting for each to complete, reducing idle time and enhancing throughput. It supports scalable architectures by enabling non-blocking operations, which is critical for handling high volumes of user requests and real-time data processing. Asynchronous control also optimizes resource utilization, leading to better system performance in cloud computing, web services, and IoT environments.

Common Use Cases for Synchronous Control

Synchronous control is commonly used in real-time communication systems, industrial automation, and audio/video streaming where precise timing and coordination between processes are crucial. It ensures consistent data transfer and accurate synchronization, minimizing latency and preventing data loss. Applications such as telecommunication networks, robotic systems, and playback devices heavily rely on synchronous control for optimal performance.

Popular Applications of Asynchronous Control

Asynchronous control is widely used in telecommunications networks, enabling efficient data transmission without the need for synchronized clocks, which enhances system flexibility and reduces latency. It plays a critical role in microprocessor interrupt handling, allowing processors to respond to real-time events dynamically, improving multitasking capabilities in embedded systems and operating systems. Industrial automation employs asynchronous control for real-time monitoring and event-driven responses, which optimize production processes and increase operational safety.

Synchronous vs Asynchronous: Performance Comparison

Synchronous control systems generally offer lower latency and more deterministic timing compared to asynchronous control, making them ideal for real-time applications where precise timing is critical. Asynchronous control, while potentially introducing variable delays due to non-blocking operations, can enhance overall system throughput and resource utilization, especially in distributed or multi-core environments. Performance comparison metrics typically highlight synchronous control as superior for tasks requiring strict timing, whereas asynchronous control excels in scalability and responsiveness under heavy loads.

Selecting the Best Control Method for Your Project

Choosing between synchronous control and asynchronous control depends on project requirements such as timing precision and system complexity. Synchronous control offers deterministic timing ideal for real-time applications where coordinated operations are critical. Asynchronous control provides flexibility and scalability, suitable for distributed systems where tasks operate independently without strict timing constraints.

Synchronous control vs Asynchronous control Infographic

libmatt.com

libmatt.com