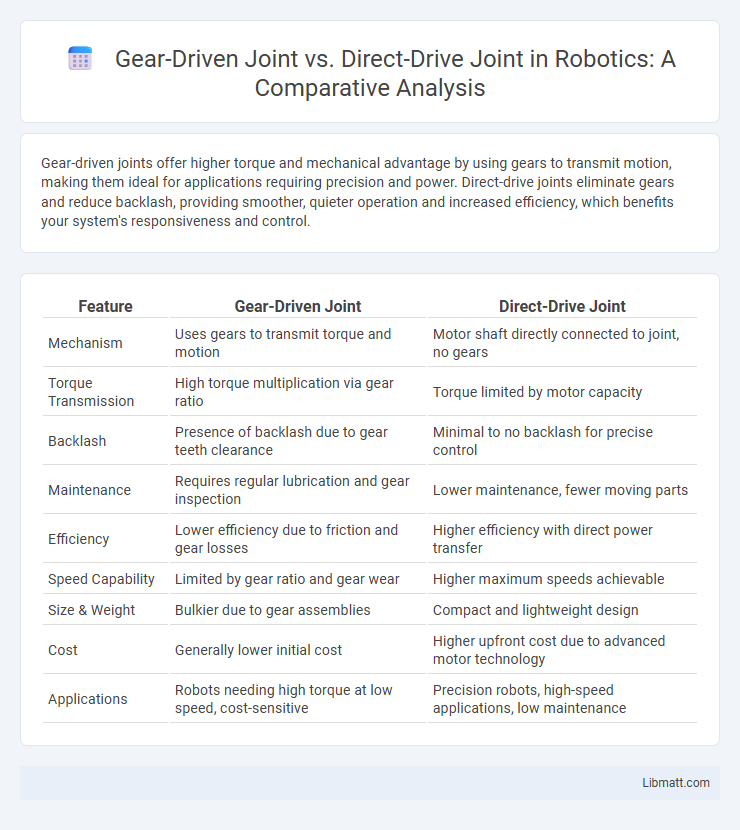

Gear-driven joints offer higher torque and mechanical advantage by using gears to transmit motion, making them ideal for applications requiring precision and power. Direct-drive joints eliminate gears and reduce backlash, providing smoother, quieter operation and increased efficiency, which benefits your system's responsiveness and control.

Table of Comparison

| Feature | Gear-Driven Joint | Direct-Drive Joint |

|---|---|---|

| Mechanism | Uses gears to transmit torque and motion | Motor shaft directly connected to joint, no gears |

| Torque Transmission | High torque multiplication via gear ratio | Torque limited by motor capacity |

| Backlash | Presence of backlash due to gear teeth clearance | Minimal to no backlash for precise control |

| Maintenance | Requires regular lubrication and gear inspection | Lower maintenance, fewer moving parts |

| Efficiency | Lower efficiency due to friction and gear losses | Higher efficiency with direct power transfer |

| Speed Capability | Limited by gear ratio and gear wear | Higher maximum speeds achievable |

| Size & Weight | Bulkier due to gear assemblies | Compact and lightweight design |

| Cost | Generally lower initial cost | Higher upfront cost due to advanced motor technology |

| Applications | Robots needing high torque at low speed, cost-sensitive | Precision robots, high-speed applications, low maintenance |

Introduction to Robotic Joint Technologies

Gear-driven joints utilize gears to transmit torque and amplify motion control precision, offering high stiffness and load capacity for robotic arms. Direct-drive joints eliminate gears by connecting the motor shaft directly to the joint, resulting in reduced backlash, enhanced responsiveness, and improved overall accuracy. Choosing between gear-driven and direct-drive joints depends on specific application requirements such as force, speed, precision, and maintenance demands in robotic systems.

Overview of Gear-Driven Joints

Gear-driven joints utilize a series of interlocking gears to transfer torque and motion between components, offering high torque amplification and precise control in robotic systems. These joints provide mechanical advantage, enabling heavy load handling and improved positional accuracy compared to direct-drive joints, which rely on direct coupling without intermediate gears. Gear-driven joints often introduce backlash and maintenance considerations but excel in applications requiring robust torque transmission and stability.

Overview of Direct-Drive Joints

Direct-drive joints provide precise motion control by eliminating gears and reducing backlash, resulting in higher accuracy and smoother operation. These joints use powerful motors directly coupled to the joint axis, enhancing responsiveness and reducing maintenance compared to gear-driven alternatives. Your robotic system benefits from increased efficiency and reliability when utilizing direct-drive joints, especially in high-precision applications.

Key Differences Between Gear-Driven and Direct-Drive Joints

Gear-driven joints use a system of gears to transmit torque, providing higher torque output and mechanical advantage, but often at the cost of increased backlash and maintenance. Direct-drive joints eliminate the intermediary gears, resulting in higher precision, lower backlash, and faster response times, making them ideal for applications requiring smooth and accurate motion control. Your choice between the two depends on the trade-off between torque requirements and the need for precision in your mechanical system.

Torque and Power Efficiency Comparison

Gear-driven joints typically offer higher torque multiplication but incur power losses due to gear friction and backlash, reducing overall efficiency. Direct-drive joints provide superior power efficiency by eliminating intermediate gears, resulting in more precise torque transmission with minimal energy loss. Your choice depends on whether maximum torque output or optimum power efficiency is prioritized in the application.

Impact on Precision and Control

Gear-driven joints offer enhanced torque multiplication and can improve control for heavy-load applications, but may introduce backlash that affects precision. Direct-drive joints eliminate mechanical play by directly coupling the motor to the joint, resulting in higher positional accuracy and smoother motion control. Your choice between these systems depends on the required balance between control fidelity and mechanical complexity in precision-critical tasks.

Maintenance and Durability Considerations

Gear-driven joints require regular lubrication and inspection to prevent wear and backlash, making maintenance more frequent compared to direct-drive joints. Direct-drive joints, with fewer moving parts and no gears, offer enhanced durability and reduced maintenance needs, ensuring longer operational life and higher precision. Choosing your joint type impacts downtime and service costs significantly, with direct-drive systems generally providing greater reliability under demanding conditions.

Cost Analysis: Gear-Driven vs Direct-Drive

Gear-driven joints typically incur lower upfront costs due to simpler motor requirements and standardized components, making them cost-effective for budget-sensitive applications. Direct-drive joints involve higher initial investment because of precision sensors and high-torque motors, but offer reduced maintenance expenses and improved reliability over time. Evaluating total cost of ownership reveals gear-driven systems may have hidden expenses from wear and backlash, while direct-drive joints minimize long-term operational costs with superior efficiency and accuracy.

Applications and Use Cases for Each Joint Type

Gear-driven joints are ideal for industrial robots requiring high torque and precise positioning in applications such as assembly lines, material handling, and CNC machines. Direct-drive joints excel in high-speed, high-precision tasks like semiconductor manufacturing, medical robotics, and aerospace systems due to their low backlash and minimal maintenance. Selecting the appropriate joint type depends on factors like torque demands, speed requirements, and system complexity.

Future Trends in Robotic Joint Design

Future trends in robotic joint design emphasize enhanced torque density and precision through the integration of advanced materials and innovative actuation methods. Gear-driven joints continue to evolve with lightweight, high-efficiency planetary gears improving durability and backlash reduction, while direct-drive joints leverage high-torque brushless motors for quieter, maintenance-free operation. Hybrid designs combining the responsiveness of direct-drive with the torque amplification of gear-driven systems are emerging to optimize performance in collaborative and industrial robotics.

Gear-driven joint vs Direct-drive joint Infographic

libmatt.com

libmatt.com