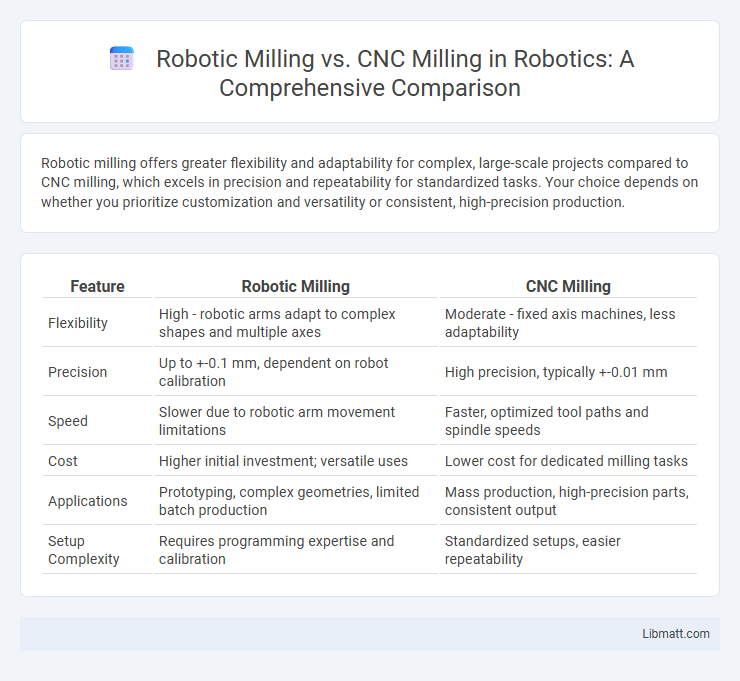

Robotic milling offers greater flexibility and adaptability for complex, large-scale projects compared to CNC milling, which excels in precision and repeatability for standardized tasks. Your choice depends on whether you prioritize customization and versatility or consistent, high-precision production.

Table of Comparison

| Feature | Robotic Milling | CNC Milling |

|---|---|---|

| Flexibility | High - robotic arms adapt to complex shapes and multiple axes | Moderate - fixed axis machines, less adaptability |

| Precision | Up to +-0.1 mm, dependent on robot calibration | High precision, typically +-0.01 mm |

| Speed | Slower due to robotic arm movement limitations | Faster, optimized tool paths and spindle speeds |

| Cost | Higher initial investment; versatile uses | Lower cost for dedicated milling tasks |

| Applications | Prototyping, complex geometries, limited batch production | Mass production, high-precision parts, consistent output |

| Setup Complexity | Requires programming expertise and calibration | Standardized setups, easier repeatability |

Introduction to Robotic Milling and CNC Milling

Robotic milling employs articulated robotic arms equipped with cutting tools for flexible, multi-axis machining, ideal for complex and large-scale workpieces. CNC milling uses computer numerical control to precisely guide traditional milling machines, delivering high accuracy and repeatability for detailed, smaller-scale manufacturing. Your choice depends on the required precision, complexity, and scale of the milling task.

How Robotic Milling Works

Robotic milling operates by utilizing articulated robotic arms equipped with cutting tools to perform precise material removal tasks, guided by computer-aided manufacturing (CAM) software. Unlike traditional CNC milling machines that move the workpiece or tool along fixed linear axes, robotic milling offers greater flexibility through multi-axis movement, enabling complex shapes and intricate designs. Understanding this technology can help you leverage its adaptability for customized production and complex geometries in manufacturing processes.

How CNC Milling Works

CNC milling operates by using computer numerical control to precisely guide cutting tools along multiple axes, shaping materials into intricate designs with high accuracy and repeatability. Your digital design is translated into G-code, which directs the machine's movements, speed, and tool changes, enabling complex and detailed machining processes. This automation reduces human error and improves production efficiency compared to robotic milling, which relies more on flexible, programmable robotic arms.

Key Differences Between Robotic and CNC Milling

Robotic milling uses articulated robotic arms to perform machining tasks with flexible movements, while CNC milling relies on rigid, computer-controlled machines with fixed axes for precision cutting. Robotic systems offer greater adaptability for complex geometries and large-scale parts but generally provide lower accuracy compared to CNC milling's high-precision, repeatable machining. CNC milling excels in producing tight tolerance components with consistent surface finishes, whereas robotic milling is preferred for custom, agile production environments.

Precision and Accuracy Comparison

Robotic milling often offers flexibility but typically lacks the precision and repeatability of CNC milling, which can achieve tolerances as tight as +-0.005 mm due to its rigid control systems and high-resolution feedback. CNC milling machines utilize advanced position encoders and closed-loop controls to maintain consistent accuracy across complex geometries, whereas robotic arms may experience positional deviations caused by joint compliance and dynamic loads. For industries requiring ultra-fine detail and stringent dimensional control, CNC milling remains the preferred choice, while robotic milling suits applications valuing adaptability over absolute precision.

Flexibility and Versatility

Robotic milling offers superior flexibility by allowing multi-axis movement and easy reprogramming for diverse and complex tasks, making it ideal for custom or small-batch production. CNC milling excels in precision and repeatability with predefined tool paths, but it can be less adaptable to design changes compared to robotic arms. Your choice depends on whether you prioritize adaptability in manufacturing or consistent high-accuracy machining processes.

Cost and Investment Considerations

Robotic milling generally involves a higher initial investment compared to CNC milling due to the complexity of robotic arms and integration requirements. CNC milling machines typically offer lower upfront costs and are more accessible for small to medium-sized operations, making them a cost-effective choice for standard machining tasks. Evaluating your production volume and flexibility needs will help determine whether the advanced capabilities of robotic milling justify the increased expense for Your manufacturing setup.

Typical Applications and Industries

Robotic milling excels in applications requiring flexible automation and complex part geometries, commonly used in aerospace for lightweight structural components and automotive for prototyping and custom parts. CNC milling dominates industries demanding high precision and consistency, such as electronics for intricate circuit boards and medical device manufacturing for surgical instruments. Both technologies serve metalworking and composite material machining but differ in scalability and operational adaptability.

Advantages and Disadvantages

Robotic milling offers greater flexibility with multi-axis movement and the ability to handle complex geometries, making it ideal for customized or small-batch production, but it often lacks the precision and repeatability found in CNC milling. CNC milling excels in high-precision, consistent manufacturing processes, providing superior accuracy and surface finish in mass production, though it may be limited by fixed tool paths and less adaptability to varied tasks. Cost efficiency depends on production scale; CNC machines are more cost-effective for large runs, while robotic milling reduces setup time and can integrate into flexible production systems.

Future Trends in Milling Technologies

Robotic milling is gaining traction due to its flexibility and ability to handle complex geometries, while CNC milling remains dominant for high-precision and repetitive tasks. Future trends indicate increased integration of AI-driven automation and machine learning algorithms to optimize tool paths and reduce cycle times in both technologies. Advancements in collaborative robots (cobots) and hybrid milling systems are expected to enhance adaptability and efficiency in manufacturing environments.

Robotic Milling vs CNC Milling Infographic

libmatt.com

libmatt.com