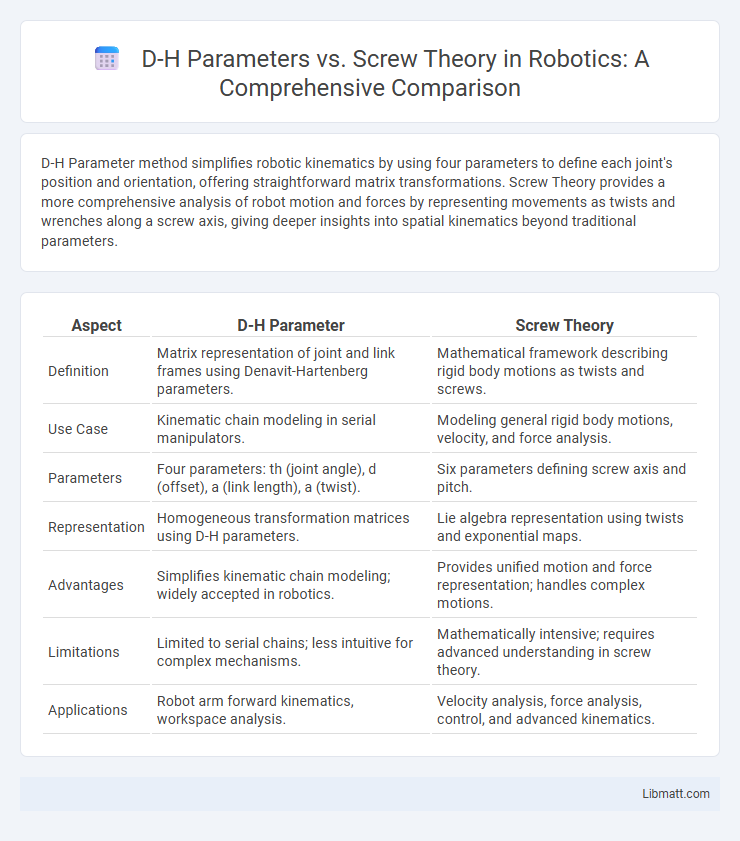

D-H Parameter method simplifies robotic kinematics by using four parameters to define each joint's position and orientation, offering straightforward matrix transformations. Screw Theory provides a more comprehensive analysis of robot motion and forces by representing movements as twists and wrenches along a screw axis, giving deeper insights into spatial kinematics beyond traditional parameters.

Table of Comparison

| Aspect | D-H Parameter | Screw Theory |

|---|---|---|

| Definition | Matrix representation of joint and link frames using Denavit-Hartenberg parameters. | Mathematical framework describing rigid body motions as twists and screws. |

| Use Case | Kinematic chain modeling in serial manipulators. | Modeling general rigid body motions, velocity, and force analysis. |

| Parameters | Four parameters: th (joint angle), d (offset), a (link length), a (twist). | Six parameters defining screw axis and pitch. |

| Representation | Homogeneous transformation matrices using D-H parameters. | Lie algebra representation using twists and exponential maps. |

| Advantages | Simplifies kinematic chain modeling; widely accepted in robotics. | Provides unified motion and force representation; handles complex motions. |

| Limitations | Limited to serial chains; less intuitive for complex mechanisms. | Mathematically intensive; requires advanced understanding in screw theory. |

| Applications | Robot arm forward kinematics, workspace analysis. | Velocity analysis, force analysis, control, and advanced kinematics. |

Introduction to D-H Parameter and Screw Theory

D-H Parameter represents a standardized method to model robotic manipulators using four parameters that define the relative positions and orientations of adjacent links. Screw Theory provides a mathematical framework combining rotational and translational motions into a single entity known as a screw, enabling compact representation of rigid body movements. Both methods are fundamental in robotics kinematics, with D-H Parameter focusing on link transformations and Screw Theory emphasizing the geometric interpretation of motion.

Fundamental Concepts of D-H Parameters

D-H parameters provide a systematic way to represent the kinematic chains of robotic manipulators through four parameters: link length, link twist, link offset, and joint angle, defining the relative transformations between adjacent coordinate frames. This method simplifies the modeling of complex robotic arms by standardizing frame assignments and utilizing homogeneous transformation matrices to describe spatial relationships. Compared to screw theory, which represents motion and forces using twists and wrenches in a more abstract geometric framework, D-H parameters offer a concrete algebraic approach focused on joint-link relationships for forward kinematics analysis.

Core Principles of Screw Theory

Screw Theory formulates rigid body motion using screw parameters that combine rotation and translation into a single entity, offering a geometric interpretation of kinematics distinct from the Denavit-Hartenberg (D-H) parameter approach. The core principles include representing motion as a six-dimensional screw axis with an associated pitch, encapsulating angular velocity and linear velocity together. This framework enables compact and invariant descriptions of twists and wrenches, facilitating advanced robot kinematics and dynamics analysis beyond the conventional D-H parameter method.

Mathematical Representation: D-H vs Screw Theory

The Denavit-Hartenberg (D-H) parameter method uses four parameters--link length, link twist, link offset, and joint angle--to represent robotic kinematics via homogeneous transformation matrices, providing a systematic way to describe joint-to-joint coordinate frames. Screw theory represents motion and forces through screw axes and pitch, encoding rotations and translations as exponential maps of twists in se(3), enabling compact and coordinate-free formulations of rigid body transformations. While D-H parameters offer stepwise coordinate transformations, screw theory provides a unified, algebraic representation that directly relates joint velocities to end-effector motion in a mathematically elegant framework.

Application in Robot Kinematics

D-H parameters provide a systematic method to represent the joint variables and link transformations in serial robotic manipulators, facilitating the forward and inverse kinematics analyses by defining rotational and translational offsets along joint axes. Screw theory offers a more general and compact framework for representing spatial motions and forces using twists and wrenches, which can model complex robot motions including instantaneous screw axes for velocity and acceleration analysis. In robot kinematics, D-H parameters excel in straightforward link-by-link modeling of serial arms, while screw theory enables advanced analysis of spatial motions, redundancies, and singularities in both serial and parallel manipulators.

Advantages and Limitations of D-H Parameters

D-H parameters offer a systematic and straightforward method to represent robot kinematics through four standardized parameters, simplifying the calculation of forward and inverse kinematics for serial manipulators. Their advantages include ease of implementation, clear geometric interpretation, and compatibility with many robotic arms, but they struggle with singularities and can become cumbersome for robots with complex joint configurations. Your use of D-H parameters may face limitations in handling non-standard joints and spatial mechanisms, where Screw Theory provides a more general and mathematically robust framework.

Advantages and Limitations of Screw Theory

Screw theory excels in representing spatial motions by combining rotational and translational components into a single mathematical framework, offering greater insight into kinematic chains and complex robot movements than the traditional D-H parameter method. It provides a more compact and unified description of rigid body motions, facilitating the analysis of velocity and force in robotic manipulators. However, screw theory can be mathematically intensive and less intuitive for beginners, whereas D-H parameters provide a simpler, more geometric approach useful for direct serial manipulator modeling, making screw theory more advantageous for advanced robotics applications requiring detailed motion and force analysis.

Comparative Analysis: Efficiency and Accuracy

D-H Parameter and Screw Theory both offer systematic approaches for modeling robot kinematics, but Screw Theory provides greater efficiency by representing spatial transformations with fewer parameters and more compact mathematical formulations. Accuracy in Screw Theory often surpasses D-H Parameter methods due to its ability to handle complex joint axes and instantaneous motion more precisely, reducing numerical errors in multi-degree-of-freedom systems. For your robotic application, choosing Screw Theory can enhance both computational speed and the fidelity of pose estimation, especially in advanced manipulator control and dynamic simulation.

Practical Use Cases in Robotics and Automation

D-H Parameter and Screw Theory both play critical roles in robotics and automation, with D-H Parameters widely used for modeling robot kinematics through joint parameters, facilitating robot arm positioning and path planning. Screw Theory provides a more comprehensive framework for describing rigid body motions and velocities, making it ideal for advanced tasks like force control and dynamic analysis in complex robotic systems. Your choice between the two depends on whether the application demands simple, clear kinematic models or detailed motion and force representation for precision control.

Future Trends: Hybrid Approaches and Integrations

Future trends in robotic kinematics emphasize hybrid approaches integrating Denavit-Hartenberg (D-H) parameters with Screw Theory to leverage their complementary strengths. Combining the systematic joint parameterization of D-H methods with the more general and geometrically intuitive framework of Screw Theory enhances accuracy and flexibility in complex motion analysis. Your robotic system's design and control can benefit from these integrated models, enabling more efficient path planning and real-time adaptability.

D-H Parameter vs Screw Theory Infographic

libmatt.com

libmatt.com