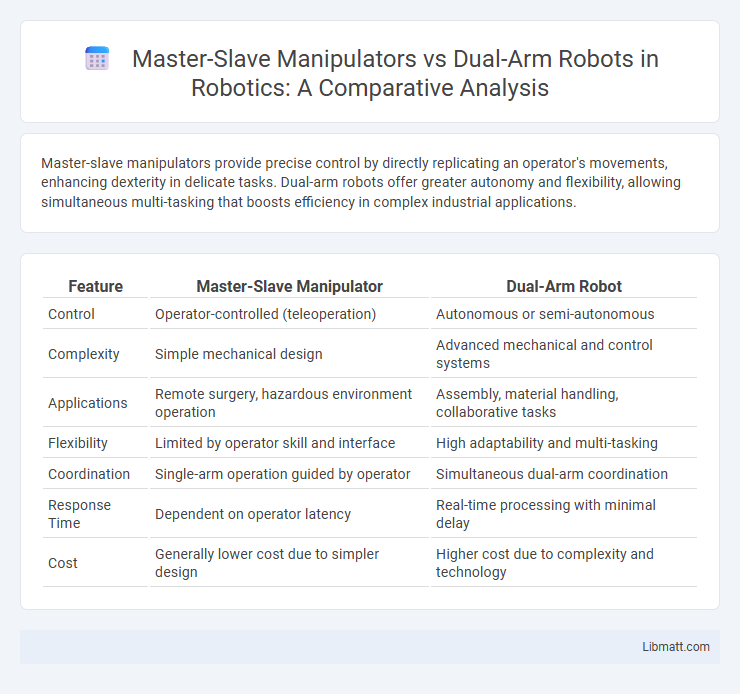

Master-slave manipulators provide precise control by directly replicating an operator's movements, enhancing dexterity in delicate tasks. Dual-arm robots offer greater autonomy and flexibility, allowing simultaneous multi-tasking that boosts efficiency in complex industrial applications.

Table of Comparison

| Feature | Master-Slave Manipulator | Dual-Arm Robot |

|---|---|---|

| Control | Operator-controlled (teleoperation) | Autonomous or semi-autonomous |

| Complexity | Simple mechanical design | Advanced mechanical and control systems |

| Applications | Remote surgery, hazardous environment operation | Assembly, material handling, collaborative tasks |

| Flexibility | Limited by operator skill and interface | High adaptability and multi-tasking |

| Coordination | Single-arm operation guided by operator | Simultaneous dual-arm coordination |

| Response Time | Dependent on operator latency | Real-time processing with minimal delay |

| Cost | Generally lower cost due to simpler design | Higher cost due to complexity and technology |

Introduction to Master-Slave Manipulators and Dual-Arm Robots

Master-slave manipulators consist of a master device controlled by a human operator that directly guides the movements of a slave robotic arm, enabling precise remote manipulation in environments hazardous or inaccessible to humans. Dual-arm robots feature two robotic arms that work collaboratively in a coordinated manner, mimicking human bimanual tasks to enhance dexterity and efficiency in complex operations such as assembly or material handling. Both systems are pivotal in advanced automation but differ primarily in control strategy and application scope, with master-slave manipulators emphasizing teleoperation and dual-arm robots specializing in autonomous or semi-autonomous task execution.

Historical Evolution of Manipulation Technologies

Master-slave manipulators originated in the mid-20th century as remote-controlled devices primarily used in hazardous environments like nuclear plants, enabling precise human control over robotic arms. Dual-arm robots have evolved from these systems by incorporating autonomous control and advanced sensor integration, allowing simultaneous bimanual operations that mimic human dexterity. Your choice between these technologies depends on whether you require direct human input or autonomous dual-arm functionality for complex manipulation tasks.

Core Principles: Master-Slave vs. Dual-Arm Robotics

Master-slave manipulators operate based on direct teleoperation where the master device controls the slave robot in real-time, ensuring precise replication of movements typically used in remote or hazardous environments. Dual-arm robots integrate two coordinated arms working simultaneously to perform complex, collaborative tasks that require synchronized motion and dexterous manipulation akin to human bimanual capabilities. Understanding these core principles helps optimize your choice between intuitive remote control and autonomous or semi-autonomous multi-arm coordination, depending on your application needs.

Control Mechanisms and Human Interaction

Master-slave manipulators rely on direct human input, translating the operator's movements into precise, real-time control of the slave arm, emphasizing intuitive human interaction and tactile feedback. Dual-arm robots feature autonomous or semi-autonomous control systems that coordinate both arms for complex tasks, often integrating advanced sensors and AI algorithms to optimize movement and task execution. Your choice depends on the required balance between manual precision and robotic autonomy in applications like surgery, manufacturing, or hazardous environment handling.

Precision, Dexterity, and Performance Comparison

Master-slave manipulators excel in precision due to direct human control, enabling fine-tuned movements in surgical or hazardous environments, while dual-arm robots offer enhanced dexterity with coordinated bimanual tasks and automated repeatability. Performance-wise, master-slave systems rely on operator skill and provide real-time feedback, whereas dual-arm robots deliver consistent, programmable actions suitable for high-throughput industrial applications. The choice between them hinges on the need for human intuition versus autonomous multitasking efficiency, balancing precision, dexterity, and operational speed.

Applications Across Industries

Master-slave manipulators excel in delicate surgical procedures, hazardous material handling, and underwater exploration due to their precise remote control capabilities. Dual-arm robots find widespread applications in manufacturing for complex assembly tasks, logistics for lifting and sorting, and service industries requiring human-like dexterity. Both technologies enhance operational efficiency and safety across aerospace, automotive, and healthcare sectors by addressing different automation needs.

Advantages and Limitations of Master-Slave Manipulators

Master-slave manipulators offer precise remote control and high dexterity, making them ideal for hazardous or microscopic environments where human presence is limited. Their primary limitation lies in the dependence on direct operator control, which can lead to fatigue and reduced efficiency during prolonged use. Unlike dual-arm robots, master-slave systems lack autonomous capabilities, restricting their function to replicating human movements rather than independent task execution.

Benefits and Challenges of Dual-Arm Robots

Dual-arm robots offer enhanced dexterity and coordination, enabling complex tasks such as assembly and material handling with greater efficiency compared to master-slave manipulators. Their ability to perform simultaneous, multi-point operations reduces cycle times and improves productivity in manufacturing environments. Challenges include the complexity of synchronization algorithms and higher costs associated with advanced control systems, which can impact integration and maintenance efforts for your automation projects.

Safety, Cost, and Scalability Considerations

Master-slave manipulators offer enhanced safety by physically isolating the operator from hazardous environments, but they often come with higher costs due to complex control systems and limited scalability for multi-tasking operations. Dual-arm robots provide increased scalability through versatile, synchronized movements and typically lower costs per unit, though they require advanced safety protocols to protect human workers in shared workspaces. Your choice depends on balancing these factors with the specific task demands and safety requirements of your application.

Future Trends in Robotic Manipulation Systems

Future trends in robotic manipulation systems emphasize enhanced autonomy and improved human-robot collaboration, moving beyond traditional master-slave manipulators toward sophisticated dual-arm robots capable of complex, synchronized tasks. Advancements in AI and sensor integration enable dual-arm robots to perform dexterous operations with greater precision and adaptability, supporting applications in manufacturing, healthcare, and service industries. Your choice between master-slave and dual-arm systems will increasingly depend on desired flexibility, task complexity, and integration with intelligent control algorithms driving next-generation automation.

Master-slave manipulator vs Dual-arm robot Infographic

libmatt.com

libmatt.com