Gravity end effectors rely on gravitational pull to securely hold objects, making them ideal for applications where minimal force and energy consumption are priorities. Vacuum end effectors use suction to grasp and manipulate items, offering strong hold and versatility for handling delicate or irregularly shaped parts, enhancing your automation efficiency.

Table of Comparison

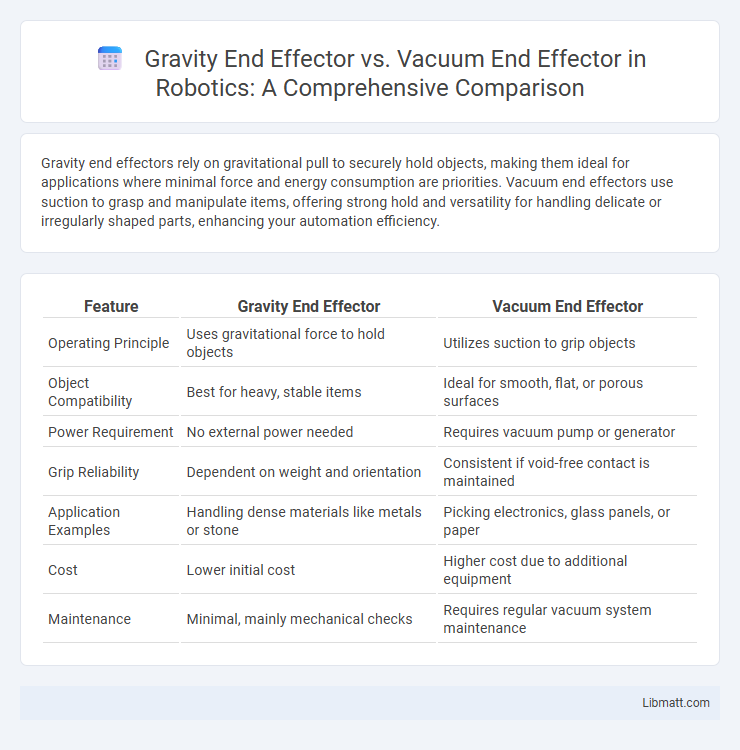

| Feature | Gravity End Effector | Vacuum End Effector |

|---|---|---|

| Operating Principle | Uses gravitational force to hold objects | Utilizes suction to grip objects |

| Object Compatibility | Best for heavy, stable items | Ideal for smooth, flat, or porous surfaces |

| Power Requirement | No external power needed | Requires vacuum pump or generator |

| Grip Reliability | Dependent on weight and orientation | Consistent if void-free contact is maintained |

| Application Examples | Handling dense materials like metals or stone | Picking electronics, glass panels, or paper |

| Cost | Lower initial cost | Higher cost due to additional equipment |

| Maintenance | Minimal, mainly mechanical checks | Requires regular vacuum system maintenance |

Introduction to End Effectors: Gravity vs Vacuum

Gravity end effectors rely on natural gravitational forces to securely hold and position parts, ideal for simple, heavy objects in automation. Vacuum end effectors use suction cups connected to a vacuum pump, creating a strong grip on smooth or porous surfaces, enhancing precision in handling delicate or irregular shapes. Choosing between gravity and vacuum end effectors depends on factors like object weight, surface texture, and required handling accuracy.

Overview of Gravity End Effectors

Gravity end effectors utilize gravitational force to grip and manipulate objects, making them ideal for handling items with consistent weight and shape. They require no external power source, increasing reliability and reducing operational costs in automated systems. Understanding your application's weight and precision requirements is crucial when choosing a gravity end effector over a vacuum alternative.

Overview of Vacuum End Effectors

Vacuum end effectors use suction to securely grip and manipulate objects, making them ideal for handling delicate or smooth surfaces without causing damage. These tools rely on vacuum pumps or generators to create negative pressure, ensuring a reliable hold for various industrial automation applications. Your choice of vacuum end effector can enhance precision and efficiency, especially in electronics, packaging, and material handling processes.

Working Principles of Gravity End Effectors

Gravity end effectors operate by utilizing the natural force of gravity to secure and release objects, relying on the weight and shape of the payload to maintain grip without the need for external power sources. These end effectors commonly feature simple mechanical components such as hooks, clamps, or grooves that engage when the object's mass applies downward force. Your choice between gravity and vacuum end effectors depends on factors like load stability, object texture, and application environment, with gravity end effectors excelling in handling heavy, irregular items without requiring pneumatic systems.

Working Principles of Vacuum End Effectors

Vacuum end effectors operate by creating a pressure difference between the suction cup and the surface of the object, using a vacuum pump or venturi system to generate negative pressure. This suction force securely lifts and holds objects with smooth, non-porous surfaces, enabling efficient handling in automation processes. Your choice between gravity and vacuum end effectors depends on the object's weight, shape, and surface type, with vacuum systems excelling in precision and delicate material handling.

Key Advantages of Gravity End Effectors

Gravity end effectors offer significant advantages including simplicity in design, lower maintenance requirements, and reduced operational costs due to the absence of powered components. Unlike vacuum end effectors, they do not rely on suction, making them ideal for handling porous, irregular, or delicate materials that could be damaged by vacuum pressure. Their passive operation ensures reliability in environments where air supply or vacuum generation is inconsistent or unavailable.

Key Advantages of Vacuum End Effectors

Vacuum end effectors offer superior versatility by securely handling a wide range of object shapes and materials, including delicate or irregular surfaces, through customized suction cups and adjustable vacuum pressure. Their ability to create a nearly instant, uniform grip reduces slippage and damage risks, making them ideal for automation in industries such as electronics, packaging, and automotive assembly. Your robotic system benefits from higher efficiency and reduced setup times compared to gravity end effectors, which rely solely on passive force and are limited to simple, gravity-dependent tasks.

Challenges and Limitations of Both Types

Gravity end effectors face challenges with precise control and stability when handling lightweight or irregularly shaped objects, limiting their applicability in delicate tasks. Vacuum end effectors often struggle with porous or uneven surfaces because maintaining a strong seal is difficult, leading to potential loss of grip and reduced reliability. Understanding these limitations helps you select the right end effector based on your object's material properties and handling requirements.

Application Scenarios: Gravity vs Vacuum End Effectors

Gravity end effectors excel in handling heavy, solid objects in environments where precision and consistent gripping force are less critical, such as in bulk material handling or palletizing tasks. Vacuum end effectors are ideal for delicate, flat, or smooth-surfaced items like glass panels, electronics, or packaging, providing gentle suction without causing damage. Your choice depends on the object's material, weight, surface texture, and the level of handling precision required in your automation process.

Choosing the Right End Effector for Your Automation Needs

Gravity end effectors offer a simple, cost-effective solution for handling heavy or irregularly shaped objects by relying on gravity and mechanical design, making them ideal for applications with minimal precision requirements. Vacuum end effectors provide higher precision and adaptability, using suction to securely grip smooth, flat, or delicate surfaces, which is essential for electronics assembly, packaging, and cleanroom environments. Selecting the right end effector depends on factors such as object weight, surface type, required precision, and environmental conditions, ensuring optimized performance and reduced operational downtime.

Gravity End Effector vs Vacuum End Effector Infographic

libmatt.com

libmatt.com