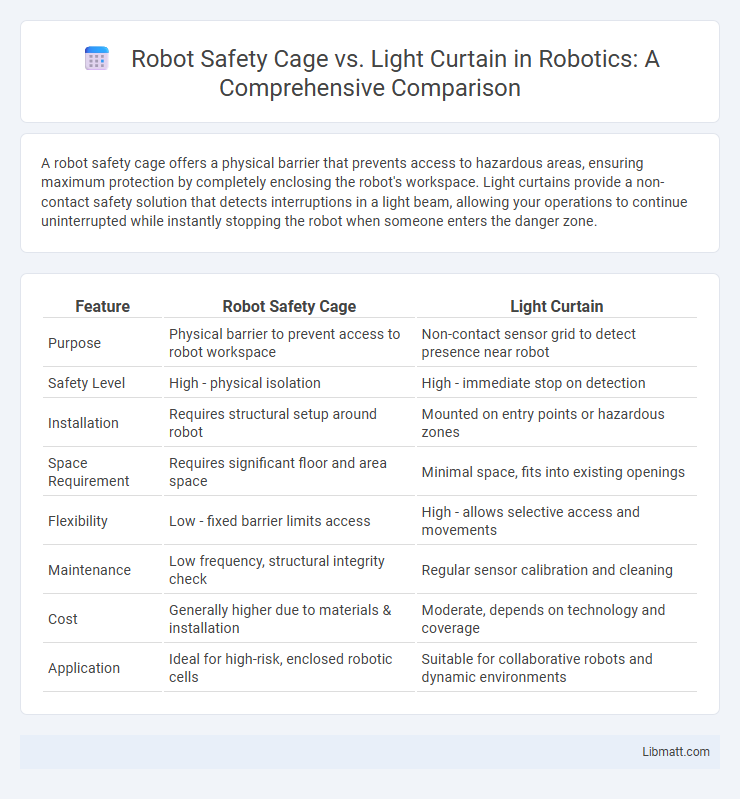

A robot safety cage offers a physical barrier that prevents access to hazardous areas, ensuring maximum protection by completely enclosing the robot's workspace. Light curtains provide a non-contact safety solution that detects interruptions in a light beam, allowing your operations to continue uninterrupted while instantly stopping the robot when someone enters the danger zone.

Table of Comparison

| Feature | Robot Safety Cage | Light Curtain |

|---|---|---|

| Purpose | Physical barrier to prevent access to robot workspace | Non-contact sensor grid to detect presence near robot |

| Safety Level | High - physical isolation | High - immediate stop on detection |

| Installation | Requires structural setup around robot | Mounted on entry points or hazardous zones |

| Space Requirement | Requires significant floor and area space | Minimal space, fits into existing openings |

| Flexibility | Low - fixed barrier limits access | High - allows selective access and movements |

| Maintenance | Low frequency, structural integrity check | Regular sensor calibration and cleaning |

| Cost | Generally higher due to materials & installation | Moderate, depends on technology and coverage |

| Application | Ideal for high-risk, enclosed robotic cells | Suitable for collaborative robots and dynamic environments |

Introduction to Robot Safety in Industrial Automation

Robot safety in industrial automation is critical to protect workers from hazards posed by robotic machinery. Robot safety cages provide physical barriers that prevent unauthorized access to dangerous zones, ensuring mechanical isolation. Light curtains offer non-contact safety measures by detecting interruptions in infrared beams, enabling flexible and dynamic safeguarding without enclosing the robot completely.

What is a Robot Safety Cage?

A Robot Safety Cage is a physical barrier designed to protect workers from hazardous robot movements by enclosing the robot's operational area, preventing accidental entry into dangerous zones. Constructed from durable materials such as steel mesh or polycarbonate panels, it ensures mechanical separation between humans and automated machinery. This containment method complies with safety standards like ISO 10218 and contributes to reducing workplace injuries by providing a clear, robust boundary around robotic cells.

Understanding Light Curtains: How They Work

Light curtains use infrared light beams to create an invisible protective barrier around hazardous areas, instantly detecting any intrusion by an object or person. When the beams are interrupted, the system sends a signal to stop the robot or machinery, ensuring immediate safety. This non-contact sensing technology allows for quick response times and flexible installation compared to traditional physical barriers like robot safety cages.

Key Differences Between Safety Cages and Light Curtains

Safety cages provide physical barriers that completely enclose robotic workspaces, ensuring maximum protection by preventing any human entry during robot operation, while light curtains use infrared beams to detect intrusion and stop the robot immediately when the beam is broken. Safety cages are ideal for high-risk environments requiring rigid containment, whereas light curtains offer flexibility and easy access for operators in less hazardous settings. Your choice depends on the level of safety required and the operational workflow, balancing comprehensive physical protection against accessibility and usability.

Safety Standards and Regulatory Compliance

Robot safety cages comply with established safety standards such as ISO 10218 and ANSI/RIA R15.06, offering a physical barrier that ensures regulatory compliance by preventing unauthorized access to hazardous robot work zones. Light curtains meet safety integrity levels defined by IEC 61496, enabling your system to stop robotic operations instantly when the safety field is breached, thus aligning with stringent regulatory safety requirements.

Installation and Space Requirements

Robot safety cages require substantial floor space and structural support for installation, often necessitating permanent fixtures to ensure a secure perimeter around robotic cells. Light curtains offer a compact, non-intrusive safety solution that can be mounted directly onto existing equipment or around work areas without extensive spatial demands. The choice between the two depends on available floor area and the need for flexibility in workspace layout, with light curtains providing a space-saving alternative to bulky safety cages.

Operational Flexibility and Workflow Impact

Robot safety cages provide robust physical barriers that limit access to hazardous areas, ensuring maximum protection but often restricting operational flexibility and slowing workflow due to necessary entry and exit procedures. Light curtains allow for safer human-robot interaction with minimal physical obstruction, enhancing workflow efficiency by enabling quicker access and dynamic operation while maintaining safety through sensor-based detection. Choosing between them depends on balancing the need for strict segmentation versus maintaining higher throughput and adaptability in automated processes.

Cost Comparison: Purchase, Installation, and Maintenance

Robot safety cages generally involve higher upfront purchase costs due to durable materials and complex structures, whereas light curtains offer a more affordable initial investment. Installation expenses for safety cages can be significant because of the need for structural modifications and labor; light curtains typically require less installation time and lower costs. Maintenance costs favor light curtains as they have fewer mechanical components and easier troubleshooting, making them a cost-effective choice for ensuring your robot's safety.

Best Applications for Robot Safety Cages vs Light Curtains

Robot safety cages are best suited for environments where complete physical separation is required to prevent human access during robot operation, such as heavy industrial welding or heavy-duty machining processes. Light curtains excel in applications requiring frequent human-robot interaction with minimal obstruction, like assembly lines or pick-and-place operations where quick access and safety are both critical. Choosing between safety cages and light curtains depends on balancing physical protection needs with operational flexibility and workflow efficiency.

Choosing the Right Safety Solution for Your Facility

Robot safety cages provide physical barriers that prevent unauthorized access to hazardous zones, ensuring maximum protection in high-risk environments. Light curtains offer flexible sensing technology that immediately stops machine operation upon intrusion, ideal for applications requiring frequent access and minimal downtime. Selecting the right safety solution depends on factors such as risk level, workspace layout, and operational workflow to optimize both safety and productivity.

Robot Safety Cage vs Light Curtain Infographic

libmatt.com

libmatt.com