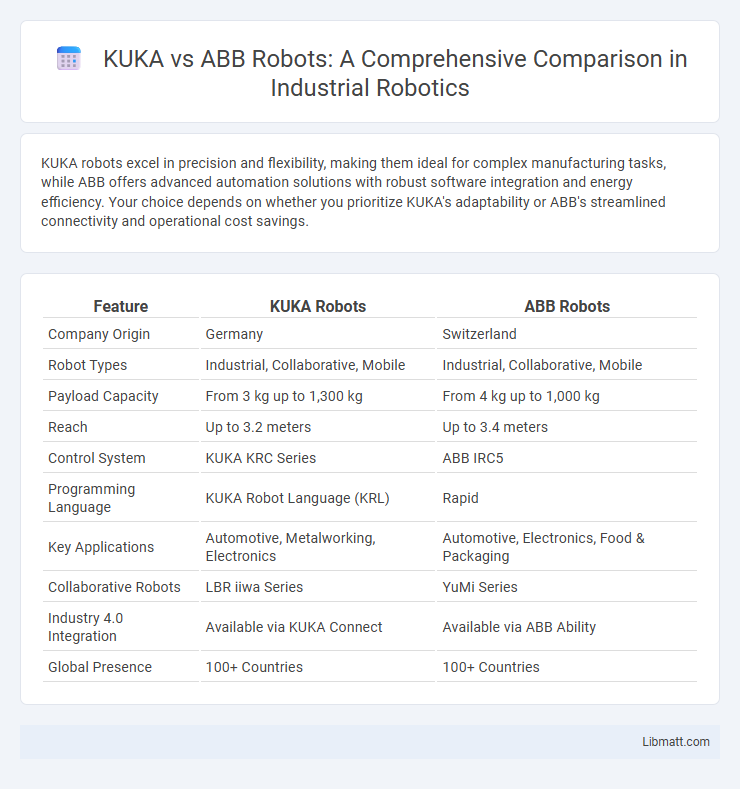

KUKA robots excel in precision and flexibility, making them ideal for complex manufacturing tasks, while ABB offers advanced automation solutions with robust software integration and energy efficiency. Your choice depends on whether you prioritize KUKA's adaptability or ABB's streamlined connectivity and operational cost savings.

Table of Comparison

| Feature | KUKA Robots | ABB Robots |

|---|---|---|

| Company Origin | Germany | Switzerland |

| Robot Types | Industrial, Collaborative, Mobile | Industrial, Collaborative, Mobile |

| Payload Capacity | From 3 kg up to 1,300 kg | From 4 kg up to 1,000 kg |

| Reach | Up to 3.2 meters | Up to 3.4 meters |

| Control System | KUKA KRC Series | ABB IRC5 |

| Programming Language | KUKA Robot Language (KRL) | Rapid |

| Key Applications | Automotive, Metalworking, Electronics | Automotive, Electronics, Food & Packaging |

| Collaborative Robots | LBR iiwa Series | YuMi Series |

| Industry 4.0 Integration | Available via KUKA Connect | Available via ABB Ability |

| Global Presence | 100+ Countries | 100+ Countries |

Introduction to KUKA and ABB Robots

KUKA and ABB Robots are leading manufacturers in industrial automation, known for their advanced robotics technology and innovative solutions in manufacturing and production lines. KUKA emphasizes precision, flexibility, and integration with Industry 4.0 systems, while ABB offers a wide range of robots featuring high payload capacities and collaborative robot models suited for various applications. Your choice between KUKA and ABB depends on the specific requirements of automation tasks, including production scale, environment, and desired robot capabilities.

Company Overview: KUKA vs ABB

KUKA, headquartered in Germany, specializes in industrial robots and automation solutions, boasting decades of experience in innovative manufacturing technologies. ABB, a Swiss-Swedish multinational corporation, offers a broader portfolio including robotics, power, and automation products, with strong global market presence and integration capabilities. Both companies excel in delivering advanced robotics systems but differ in scope, with KUKA focusing primarily on robotics and ABB leveraging its diverse industrial automation expertise.

Core Technologies and Innovations

KUKA excels with its advanced robotic arm design featuring lightweight carbon fiber materials and integrated artificial intelligence for adaptive manufacturing processes. ABB leverages its proprietary ABB Ability digital platform, enabling seamless connectivity, real-time data analytics, and enhanced precision through machine learning algorithms. Your choice depends on whether you prioritize KUKA's innovative material engineering or ABB's cutting-edge digital integration for automation solutions.

Product Line Comparison

KUKA offers versatile industrial robots with a focus on heavy payload capabilities ranging from 6 to 1,300 kg, suitable for automotive and manufacturing sectors, while ABB provides a broader product line including collaborative robots (YuMi series) and specialized models for precision tasks with payloads from 0.5 to 500 kg. Both manufacturers feature robust automation solutions with KUKA emphasizing flexible, high-payload robots like the KR QUANTEC series and ABB delivering advanced control software in their IRB series for enhanced productivity. ABB's portfolio integrates motion control and AI-driven features, whereas KUKA prioritizes modular design and ease of integration across diverse industrial applications.

Performance and Precision Analysis

KUKA robots excel in delivering high payload capacity and repeatability within +-0.05 mm, making them ideal for heavy-duty industrial applications requiring precise handling. ABB robots offer superior speed combined with advanced motion control algorithms, achieving precision down to +-0.02 mm, which is critical for tasks demanding intricate accuracy such as electronics assembly. Your choice between KUKA and ABB should align with specific performance needs, balancing payload, speed, and precision requirements for optimal operational efficiency.

Programming and Software Capabilities

KUKA robots feature the KUKA Robot Language (KRL) and offer software solutions like KUKA.WorkVisual for seamless offline programming and diagnostics. ABB robots utilize RAPID programming language and RobotStudio software, providing advanced simulation, offline programming, and virtual commissioning tools. Both brands support integration with third-party software and expandability through ROS, but ABB's RobotStudio is often lauded for its user-friendly interface and comprehensive simulation environment.

Integration and Compatibility

KUKA robots offer seamless integration with various industrial automation systems due to their open architecture and compatibility with standard communication protocols like OPC UA and EtherCAT. ABB robots excel in compatibility by providing a wide range of pre-configured software plugins and extensive support for major PLC platforms, enhancing your ability to integrate with existing manufacturing workflows. Both brands ensure reliable interoperability with third-party devices, but your choice will depend on specific system requirements and software ecosystem preferences.

Industry Applications and Use Cases

KUKA robots excel in automotive manufacturing and heavy industry applications due to their high payload capacity and precise motion control, making them ideal for welding, assembly, and material handling tasks. ABB robots are widely used in electronics, food packaging, and pharmaceutical industries, offering advanced vision systems and flexible automation solutions tailored for delicate and high-speed applications. Your choice between KUKA and ABB should consider the specific industry requirements and use cases, such as the need for robustness in heavy-duty tasks or precision in sensitive environments.

Customer Support and Service

KUKA offers extensive global customer support with localized service centers providing rapid on-site assistance and comprehensive maintenance packages. ABB emphasizes a strong digital support ecosystem, including remote diagnostics, real-time monitoring, and predictive maintenance to minimize downtime. Both companies prioritize customer satisfaction through tailored training programs and dedicated technical support teams to ensure optimal robot performance.

Cost Efficiency and ROI

KUKA robots generally offer a balance between initial investment and long-term cost efficiency, benefiting industries with moderate to high production volumes through reliable performance and reduced maintenance requirements. ABB robots, known for their advanced automation technology and energy-efficient designs, often deliver faster return on investment (ROI) by enhancing productivity and minimizing downtime in high-precision applications. Both brands provide strong ROI potential, but ABB's integrated software solutions and flexible configurations typically optimize overall cost efficiency in complex manufacturing environments.

KUKA vs ABB Robot Infographic

libmatt.com

libmatt.com