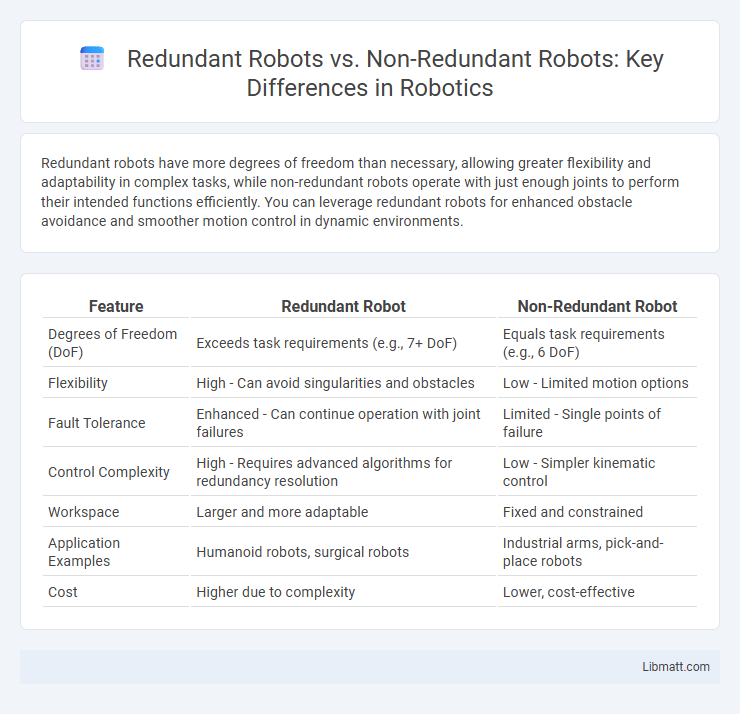

Redundant robots have more degrees of freedom than necessary, allowing greater flexibility and adaptability in complex tasks, while non-redundant robots operate with just enough joints to perform their intended functions efficiently. You can leverage redundant robots for enhanced obstacle avoidance and smoother motion control in dynamic environments.

Table of Comparison

| Feature | Redundant Robot | Non-Redundant Robot |

|---|---|---|

| Degrees of Freedom (DoF) | Exceeds task requirements (e.g., 7+ DoF) | Equals task requirements (e.g., 6 DoF) |

| Flexibility | High - Can avoid singularities and obstacles | Low - Limited motion options |

| Fault Tolerance | Enhanced - Can continue operation with joint failures | Limited - Single points of failure |

| Control Complexity | High - Requires advanced algorithms for redundancy resolution | Low - Simpler kinematic control |

| Workspace | Larger and more adaptable | Fixed and constrained |

| Application Examples | Humanoid robots, surgical robots | Industrial arms, pick-and-place robots |

| Cost | Higher due to complexity | Lower, cost-effective |

Understanding Redundant and Non-Redundant Robots

Redundant robots feature more joints than necessary for a given task, enhancing flexibility and fault tolerance by allowing multiple joint configurations to achieve the same end-effector position. Non-redundant robots have exactly the number of joints needed, simplifying control but limiting adaptability in complex environments. Understanding the distinction helps optimize Your robotic system design for efficiency, precision, and task complexity.

Key Differences Between Redundant and Non-Redundant Robots

Redundant robots have more degrees of freedom than necessary for a given task, allowing enhanced flexibility, obstacle avoidance, and fault tolerance compared to non-redundant robots, which have exactly the minimum degrees of freedom required. Non-redundant robots typically exhibit simpler kinematics and control algorithms but lack the adaptability and precision afforded by redundant systems in complex environments. The redundancy in robots increases computational complexity but enables smoother trajectories and improved performance in dynamic, unpredictable tasks.

Advantages of Redundant Robots

Redundant robots offer increased flexibility and dexterity by possessing extra degrees of freedom beyond the minimum required for a task, enabling complex maneuvers and obstacle avoidance in constrained environments. They provide enhanced fault tolerance, allowing continuous operation even if one joint or actuator fails, which improves reliability in critical applications like surgery or manufacturing. Redundant designs also allow for optimized motion planning and better control of stiffness and payload distribution, resulting in improved precision and efficiency in robotic operations.

Limitations of Non-Redundant Robots

Non-redundant robots have a limited number of joints equal to their task space dimensions, restricting their ability to avoid obstacles or singularities during operation. These limitations can lead to reduced maneuverability, increased risk of reaching singular positions where control becomes unstable, and less flexibility in optimizing motion trajectories. Your robotic applications may suffer from decreased efficiency and adaptability due to these inherent constraints in non-redundant robot designs.

Applications Suited for Redundant Robots

Redundant robots excel in applications requiring high precision, flexibility, and adaptability, such as complex assembly tasks, surgical procedures, and intricate material handling. Their multiple degrees of freedom allow for obstacle avoidance and continuous operation even if some joints fail, making them ideal for environments where reliability and maneuverability are critical. Industries like aerospace, automotive manufacturing, and medical technology benefit significantly from the advanced capabilities of redundant robotic systems.

Tasks Best Handled by Non-Redundant Robots

Non-redundant robots excel in tasks requiring precise, straightforward motion with limited degrees of freedom, such as simple pick-and-place operations or repetitive assembly line work. Their streamlined kinematics facilitate faster movement and easier programming in environments where complex maneuvering or obstacle avoidance is minimal. These robots are well-suited for consistent, high-speed tasks in manufacturing sectors like electronics assembly and packaging where accuracy and efficiency are critical.

Performance and Efficiency Comparison

Redundant robots offer enhanced performance through increased degrees of freedom, allowing for greater flexibility, fault tolerance, and improved accuracy in complex tasks compared to non-redundant robots. Non-redundant robots typically demonstrate higher efficiency in simpler applications due to their straightforward kinematics and lower computational requirements. Performance optimization in redundant robots often comes at the cost of increased energy consumption and computational load, while non-redundant robots excel in speed and resource efficiency during repetitive or well-defined operations.

Flexibility in Industrial Automation

Redundant robots feature multiple backup components, enabling enhanced flexibility by maintaining operation despite individual part failures, which is critical in complex industrial automation tasks requiring continuous uptime. Non-redundant robots lack such backup systems, offering simpler, more cost-effective solutions but with limited adaptability and increased risk of downtime during malfunctions. In high-stakes manufacturing environments, redundant robots provide superior fault tolerance and dynamic task reconfiguration, boosting overall system resilience and productivity.

Cost Implications: Redundant vs Non-Redundant Robots

Redundant robots, equipped with extra joints or axes, typically incur higher costs due to increased mechanical complexity and advanced control systems compared to non-redundant robots. Your investment in redundant robots can lead to greater operational flexibility and fault tolerance, potentially reducing downtime and long-term maintenance expenses. Non-redundant robots generally offer a lower upfront cost but may face limitations in adaptability and higher risks of operational disruptions.

Choosing the Right Robot for Your Application

Selecting the right robot for your application depends on factors such as task complexity, precision requirements, and workspace constraints. Redundant robots, featuring extra degrees of freedom, offer enhanced flexibility and obstacle avoidance, making them ideal for intricate tasks in constrained environments. Non-redundant robots provide simpler, more cost-effective solutions for straightforward applications where precision and flexibility demands are moderate.

Redundant Robot vs Non-Redundant Robot Infographic

libmatt.com

libmatt.com