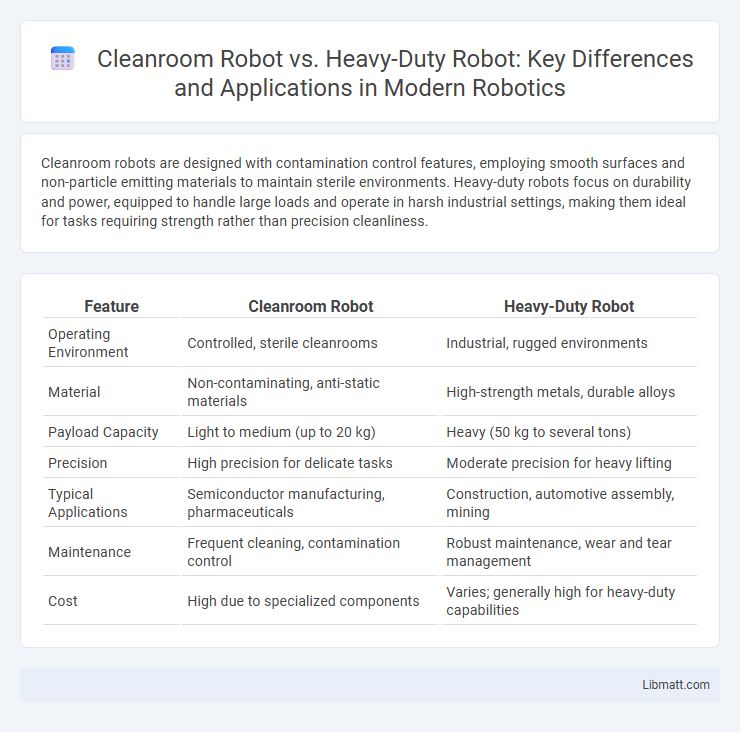

Cleanroom robots are designed with contamination control features, employing smooth surfaces and non-particle emitting materials to maintain sterile environments. Heavy-duty robots focus on durability and power, equipped to handle large loads and operate in harsh industrial settings, making them ideal for tasks requiring strength rather than precision cleanliness.

Table of Comparison

| Feature | Cleanroom Robot | Heavy-Duty Robot |

|---|---|---|

| Operating Environment | Controlled, sterile cleanrooms | Industrial, rugged environments |

| Material | Non-contaminating, anti-static materials | High-strength metals, durable alloys |

| Payload Capacity | Light to medium (up to 20 kg) | Heavy (50 kg to several tons) |

| Precision | High precision for delicate tasks | Moderate precision for heavy lifting |

| Typical Applications | Semiconductor manufacturing, pharmaceuticals | Construction, automotive assembly, mining |

| Maintenance | Frequent cleaning, contamination control | Robust maintenance, wear and tear management |

| Cost | High due to specialized components | Varies; generally high for heavy-duty capabilities |

Introduction to Cleanroom Robots vs Heavy-Duty Robots

Cleanroom robots are specially designed for contamination-sensitive environments, using non-particle generating materials and precise movements to maintain sterile conditions. Heavy-duty robots, by contrast, are constructed with robust materials and powerful actuators to handle demanding industrial tasks such as welding, lifting, and assembly in harsh environments. The key distinction lies in cleanroom robots' focus on minimizing contamination and heavy-duty robots' emphasis on strength and durability in rugged conditions.

Key Design Differences

Cleanroom robots feature sealed, sterilizable surfaces and smooth exteriors to prevent particle contamination, adhering to strict ISO cleanliness standards unlike heavy-duty robots which prioritize rugged construction with reinforced frames and protective guards for durability in harsh industrial environments. Cleanroom robots utilize non-lubricated or sealed bearings and stainless steel components to minimize particulate generation, whereas heavy-duty robots employ robust motors and high-torque gearboxes designed for heavy lifting and impact resistance. The precision and compact design of cleanroom robots contrast with the larger, more powerful build of heavy-duty robots, reflecting their specialized functions in contamination-controlled versus high-stress operational settings.

Operational Environments

Cleanroom robots operate in controlled environments with stringent cleanliness standards, essential for industries like pharmaceuticals and semiconductors to prevent contamination. Heavy-duty robots are designed for harsh operational environments such as construction sites, manufacturing plants, and warehouses, where they handle heavy loads, withstand dust, and resist impact. Selecting a robot based on your specific operational environment ensures optimal performance and longevity tailored to your industrial needs.

Material and Build Specifications

Cleanroom robots are constructed using non-corrosive, anti-microbial materials such as stainless steel and special polymers to prevent contamination and ensure compliance with stringent hygiene standards. Their design emphasizes smooth surfaces and sealed joints to minimize particle generation, while heavy-duty robots use robust steel frames, reinforced joints, and high-torque actuators for durability in industrial environments. Your choice between these robots depends on the specific material and build requirements suited to either sterile cleanroom conditions or demanding heavy-load applications.

Precision and Performance Capabilities

Cleanroom robots deliver exceptional precision with micron-level accuracy, designed for contamination-free environments in semiconductor manufacturing and pharmaceutical applications. Heavy-duty robots excel in performance capabilities such as high payload capacity, robust durability, and extended operational range, ideal for automotive assembly and heavy material handling. The choice between cleanroom and heavy-duty robots depends on application-specific demands for precision versus strength and environmental control.

Common Applications

Cleanroom robots are essential in semiconductor manufacturing, pharmaceuticals, and medical device assembly, where contamination control and precision are critical. Heavy-duty robots excel in automotive assembly, metal fabrication, and heavy machinery handling, performing tasks that require high payload capacity and durability. Your choice depends on the specific industry requirements and the environmental conditions where the robotic system will operate.

Maintenance and Safety Requirements

Cleanroom robots require stringent maintenance protocols involving regular sterilization and contamination control to maintain ISO class standards, ensuring minimal particle generation during operation. Heavy-duty robots demand robust maintenance routines focused on lubrication, inspection of mechanical parts, and safeguarding against wear and tear under high-load conditions to prevent operational failures. Safety requirements for cleanroom robots emphasize strict compliance with clean environment regulations and worker protection from contamination, while heavy-duty robots prioritize industrial safety measures including guarding, emergency stops, and hazard detection systems to mitigate risks in heavy manufacturing environments.

Cost Comparison

Cleanroom robots typically incur higher initial costs due to specialized materials and certifications required for contamination control, while heavy-duty robots offer lower upfront expenses but may involve greater long-term maintenance costs. Your choice depends on balancing the short-term investment against operational efficiency and compliance needs in sensitive environments. Cost analysis should consider not only purchase price but also lifecycle expenses, including downtime and regulatory adherence.

Integration with Automation Systems

Cleanroom robots excel in seamless integration with precision automation systems, ensuring contamination-free operations in sensitive environments like pharmaceuticals and electronics manufacturing. Heavy-duty robots provide robust compatibility with industrial automation platforms, handling high-load tasks in sectors such as automotive and metal fabrication. Your choice depends on whether clean, controlled environments or heavy material handling and durability drive your automation goals.

Future Trends and Innovations

Cleanroom robots are evolving with advancements in precision engineering and contamination control, integrating IoT sensors and AI for real-time monitoring and adaptive responses in sterile environments. Heavy-duty robots are trending towards enhanced payload capacity and durability, incorporating autonomous navigation and machine learning to optimize heavy industrial tasks and reduce downtime. Emerging innovations include hybrid designs combining cleanroom compliance with robust performance, potentially transforming manufacturing processes across pharmaceutical, semiconductor, and automotive industries.

Cleanroom robot vs Heavy-duty robot Infographic

libmatt.com

libmatt.com