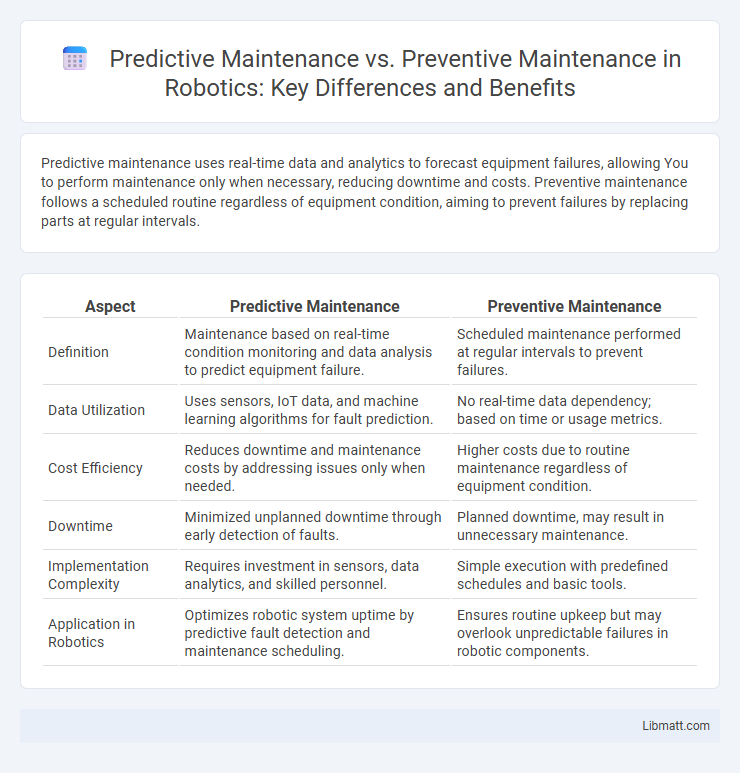

Predictive maintenance uses real-time data and analytics to forecast equipment failures, allowing You to perform maintenance only when necessary, reducing downtime and costs. Preventive maintenance follows a scheduled routine regardless of equipment condition, aiming to prevent failures by replacing parts at regular intervals.

Table of Comparison

| Aspect | Predictive Maintenance | Preventive Maintenance |

|---|---|---|

| Definition | Maintenance based on real-time condition monitoring and data analysis to predict equipment failure. | Scheduled maintenance performed at regular intervals to prevent failures. |

| Data Utilization | Uses sensors, IoT data, and machine learning algorithms for fault prediction. | No real-time data dependency; based on time or usage metrics. |

| Cost Efficiency | Reduces downtime and maintenance costs by addressing issues only when needed. | Higher costs due to routine maintenance regardless of equipment condition. |

| Downtime | Minimized unplanned downtime through early detection of faults. | Planned downtime, may result in unnecessary maintenance. |

| Implementation Complexity | Requires investment in sensors, data analytics, and skilled personnel. | Simple execution with predefined schedules and basic tools. |

| Application in Robotics | Optimizes robotic system uptime by predictive fault detection and maintenance scheduling. | Ensures routine upkeep but may overlook unpredictable failures in robotic components. |

Introduction to Maintenance Strategies

Predictive maintenance uses real-time data and advanced analytics to forecast equipment failures before they occur, optimizing maintenance schedules and reducing downtime. Preventive maintenance follows a fixed schedule based on time or usage intervals to perform regular inspections and servicing, aiming to prevent unexpected breakdowns. Your choice between these strategies depends on factors like equipment criticality, maintenance costs, and availability of monitoring technology.

Defining Predictive Maintenance

Predictive maintenance uses real-time data and advanced analytics to monitor equipment condition and predict failures before they occur, allowing for maintenance only when necessary. This approach relies heavily on IoT sensors, machine learning algorithms, and historical data to optimize maintenance schedules and reduce downtime. In contrast, preventive maintenance follows a fixed schedule regardless of equipment condition, potentially leading to unnecessary maintenance or unexpected breakdowns.

Understanding Preventive Maintenance

Preventive maintenance involves regularly scheduled inspections and servicing of equipment to prevent unexpected failures and extend asset lifespan. This strategy relies on time-based intervals or usage triggers to perform tasks such as lubrication, adjustments, and parts replacement before problems occur. Understanding preventive maintenance helps you optimize operational efficiency by reducing downtime and minimizing costly repairs.

Key Differences Between Predictive and Preventive Maintenance

Predictive maintenance leverages real-time data and advanced analytics, such as IoT sensors and machine learning algorithms, to forecast equipment failures, enabling condition-based interventions only when necessary. Preventive maintenance relies on scheduled inspections and routine servicing based on time or usage intervals, regardless of equipment condition, to reduce the risk of unexpected breakdowns. Key differences include the reliance on data-driven diagnostics in predictive maintenance versus fixed maintenance schedules in preventive maintenance, impacting cost efficiency, downtime reduction, and resource allocation.

Advantages of Predictive Maintenance

Predictive maintenance offers significant advantages by utilizing real-time data and advanced analytics to accurately forecast equipment failures, thereby minimizing unplanned downtime and reducing maintenance costs. This approach extends the lifespan of machinery through timely interventions based on actual condition rather than fixed schedules, optimizing resource allocation. Organizations adopting predictive maintenance benefit from improved operational efficiency, enhanced safety, and reduced inventory costs related to spare parts.

Benefits of Preventive Maintenance

Preventive maintenance extends equipment lifespan by scheduling regular inspections and servicing, reducing the likelihood of unexpected failures. It enhances safety and reliability, ensuring operations run smoothly and minimizing costly downtime. Your business benefits from predictable maintenance costs and improved asset performance through a structured preventive maintenance plan.

Cost Analysis: Predictive vs Preventive Maintenance

Predictive maintenance utilizes real-time data and condition-monitoring sensors to reduce unexpected failures, resulting in lower overall maintenance costs compared to preventive maintenance, which relies on scheduled interventions regardless of actual equipment condition. Preventive maintenance often leads to higher labor and parts expenses due to unnecessary replacements and downtime, while predictive maintenance optimizes maintenance scheduling by targeting only necessary repairs. Cost analysis shows predictive maintenance can reduce maintenance costs by 10-40%, increase equipment lifespan, and improve operational efficiency.

Technological Requirements for Each Approach

Predictive maintenance relies heavily on advanced technologies such as IoT sensors, real-time data analytics, machine learning algorithms, and cloud computing to monitor equipment condition and predict failures accurately. Preventive maintenance, on the other hand, depends primarily on scheduled inspections, manual tracking systems, and historical maintenance records, which require less sophisticated technology but more routine labor. The integration of SCADA systems and condition monitoring tools is essential for predictive maintenance, whereas preventive maintenance often utilizes basic CMMS software for planning and workflow management.

Industry Applications and Use Cases

Predictive maintenance leverages IoT sensors and machine learning algorithms to monitor real-time equipment conditions, optimizing maintenance schedules in industries like manufacturing, oil and gas, and aviation, thereby reducing unplanned downtime and operational costs. Preventive maintenance, based on fixed schedules or usage metrics, is widely used in automotive, utilities, and HVAC systems to prevent failures by performing regular inspections and part replacements. In sectors such as energy and transportation, combining both strategies enhances asset reliability and extends machinery lifespan through data-driven insights and routine upkeep.

Choosing the Right Maintenance Strategy

Choosing the right maintenance strategy depends on your operational goals, budget, and asset criticality. Predictive maintenance leverages real-time data and advanced analytics to forecast equipment failures, reducing downtime and unnecessary maintenance costs. Preventive maintenance relies on scheduled intervals to minimize breakdowns but may lead to over-maintenance if not aligned with actual equipment conditions.

Predictive maintenance vs Preventive maintenance Infographic

libmatt.com

libmatt.com