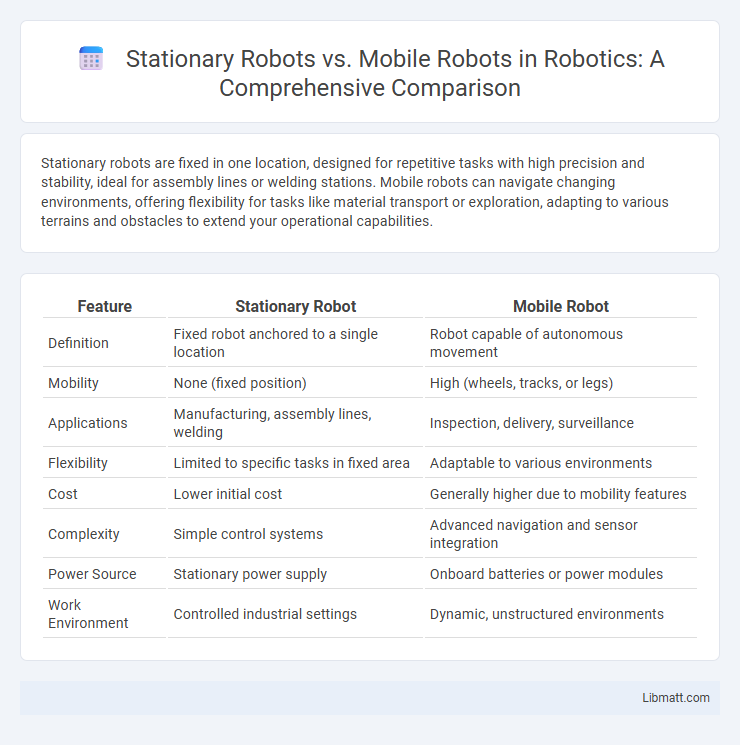

Stationary robots are fixed in one location, designed for repetitive tasks with high precision and stability, ideal for assembly lines or welding stations. Mobile robots can navigate changing environments, offering flexibility for tasks like material transport or exploration, adapting to various terrains and obstacles to extend your operational capabilities.

Table of Comparison

| Feature | Stationary Robot | Mobile Robot |

|---|---|---|

| Definition | Fixed robot anchored to a single location | Robot capable of autonomous movement |

| Mobility | None (fixed position) | High (wheels, tracks, or legs) |

| Applications | Manufacturing, assembly lines, welding | Inspection, delivery, surveillance |

| Flexibility | Limited to specific tasks in fixed area | Adaptable to various environments |

| Cost | Lower initial cost | Generally higher due to mobility features |

| Complexity | Simple control systems | Advanced navigation and sensor integration |

| Power Source | Stationary power supply | Onboard batteries or power modules |

| Work Environment | Controlled industrial settings | Dynamic, unstructured environments |

Introduction to Stationary and Mobile Robots

Stationary robots are fixed in one location and designed for repetitive tasks such as assembly, welding, and packaging within manufacturing environments. Mobile robots possess autonomous navigation capabilities, enabling them to move freely in dynamic spaces for applications like delivery, inspection, and exploration. Both types utilize sensors, actuators, and advanced control systems, but their operational domains and degrees of mobility distinguish their functional roles.

Definitions: Stationary vs Mobile Robots

Stationary robots are fixed in one location, designed to perform repetitive tasks with high precision in controlled environments like assembly lines or manufacturing plants. Mobile robots, equipped with locomotion systems such as wheels or tracks, navigate dynamic spaces to perform tasks including delivery, inspection, or exploration. Understanding the distinction helps you select the appropriate robot type based on the operational environment and task requirements.

Core Components and Technologies

Stationary robots typically feature fixed bases with articulated arms equipped with sensors, actuators, and control systems designed for precision tasks in manufacturing or assembly lines. Mobile robots incorporate core technologies such as wheels or tracks for locomotion, sensors like LiDAR or cameras for environmental mapping, and advanced navigation algorithms enabling autonomous movement in dynamic environments. Understanding the distinction in these core components helps optimize your selection based on application requirements, whether you need precise manipulation or versatile mobility.

Key Applications and Use Cases

Stationary robots excel in repetitive manufacturing tasks such as welding, assembly, and packaging within controlled environments, delivering high precision and efficiency in automotive and electronics industries. Mobile robots offer versatility for dynamic applications including warehouse logistics, autonomous delivery, and surveillance, adapting to varied terrains and operational contexts. Your choice depends on whether fixed process automation or flexible task mobility aligns better with your operational goals.

Mobility: Advantages and Limitations

Stationary robots offer precise, stable operation ideal for repetitive tasks in controlled environments but lack flexibility due to their fixed position. Mobile robots provide significant advantages in navigating dynamic spaces, enabling Your system to perform diverse functions across multiple locations. However, mobile robots face limitations such as battery dependency, complex navigation challenges, and potential stability issues compared to their stationary counterparts.

Deployment Challenges and Considerations

Stationary robots require precise environmental setup and fixed infrastructure, posing challenges related to installation time and workspace limitations. Mobile robots face navigation, obstacle avoidance, and battery life issues, demanding advanced sensors and adaptive software for efficient deployment. Your choice should consider operational flexibility, maintenance complexity, and the specific tasks' spatial dynamics.

Cost and Maintenance Comparison

Stationary robots generally have lower initial costs and maintenance expenses due to fixed installations and fewer moving parts, leading to reduced wear and tear. Mobile robots, while offering greater operational flexibility, typically incur higher costs from complex navigation systems, batteries, and frequent hardware replacements. Maintenance for mobile robots is more intensive and costly because of their exposure to variable environments and mechanical stress during movement.

Integration with Industry 4.0

Stationary robots excel in precision and consistent task execution, seamlessly integrating with Industry 4.0 through fixed automation systems and real-time data exchange on manufacturing floors. Mobile robots enhance flexibility by navigating dynamic environments, supporting decentralized production with IoT connectivity and adaptive workflows. Your choice depends on whether fixed accuracy or versatile movement better aligns with your Industry 4.0 automation strategy.

Future Trends in Robotics

Future trends in robotics emphasize the integration of advanced AI and machine learning to enhance the capabilities of both stationary robots and mobile robots, improving precision and autonomy. Stationary robots are increasingly being equipped with collaborative features to work safely alongside humans in manufacturing and medical settings, while mobile robots are advancing in navigation technologies like SLAM (Simultaneous Localization and Mapping) for more efficient autonomous movement in dynamic environments. The convergence of IoT connectivity and cloud computing further accelerates the development of smart robotic systems capable of real-time data processing and remote operation.

Choosing the Right Robot for Your Needs

Choosing the right robot depends heavily on your specific application requirements and operational environment. Stationary robots excel in precision tasks within fixed locations, such as assembly lines or welding stations, offering high repeatability and payload capacity. Mobile robots provide flexibility and adaptability for dynamic environments, making them ideal for material transport, inspection, and areas where space or layout frequently changes.

Stationary Robot vs Mobile Robot Infographic

libmatt.com

libmatt.com