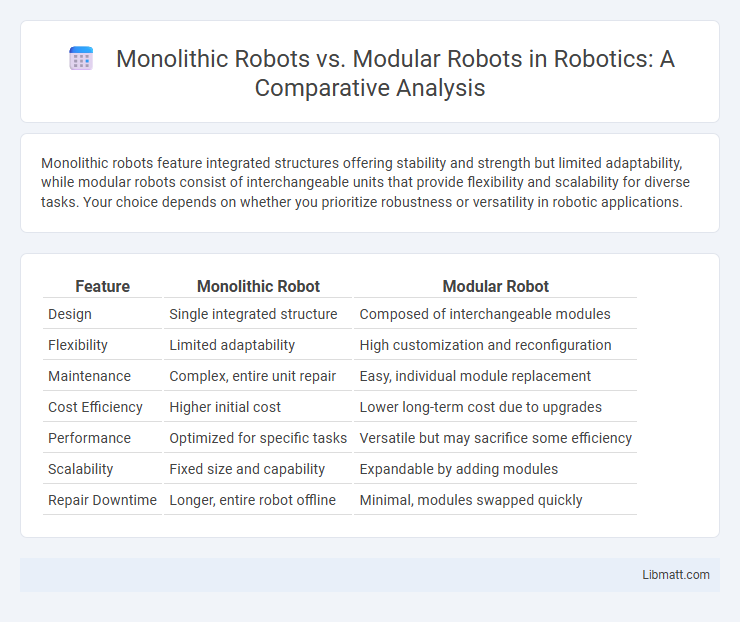

Monolithic robots feature integrated structures offering stability and strength but limited adaptability, while modular robots consist of interchangeable units that provide flexibility and scalability for diverse tasks. Your choice depends on whether you prioritize robustness or versatility in robotic applications.

Table of Comparison

| Feature | Monolithic Robot | Modular Robot |

|---|---|---|

| Design | Single integrated structure | Composed of interchangeable modules |

| Flexibility | Limited adaptability | High customization and reconfiguration |

| Maintenance | Complex, entire unit repair | Easy, individual module replacement |

| Cost Efficiency | Higher initial cost | Lower long-term cost due to upgrades |

| Performance | Optimized for specific tasks | Versatile but may sacrifice some efficiency |

| Scalability | Fixed size and capability | Expandable by adding modules |

| Repair Downtime | Longer, entire robot offline | Minimal, modules swapped quickly |

Introduction to Monolithic and Modular Robots

Monolithic robots are built as a single, unified structure with integrated components designed for specific tasks, offering high precision and stability. Modular robots consist of multiple interchangeable units or modules that can be reconfigured to perform various functions, providing flexibility and adaptability. Your choice between monolithic and modular robots depends on whether your application prioritizes specialized performance or versatile reusability.

Key Differences Between Monolithic and Modular Robotics

Monolithic robots consist of a single, unified structure with fixed components, offering high precision and rigidity ideal for specialized tasks. Modular robots feature interchangeable and reconfigurable units, providing flexibility and adaptability for varied applications in dynamic environments. Your choice depends on the need for customization versus stability in robotic operations.

Structural Design Comparison: Monolithic vs Modular

Monolithic robots feature a single, unified structure offering high rigidity and precise control but limited adaptability and repair options. Modular robots consist of multiple interchangeable units, enhancing flexibility, scalability, and fault tolerance through reconfiguration and easy replacement. Structural design in monolithic systems prioritizes strength and stability, whereas modular designs emphasize versatility and customizable functionality.

Flexibility and Adaptability in Robotics Architecture

Modular robots exhibit superior flexibility and adaptability compared to monolithic robots due to their reconfigurable architecture, allowing individual modules to be rearranged or replaced to perform varied tasks or adapt to changing environments. Monolithic robots, characterized by a fixed structure and integrated components, offer limited ability to modify their physical form or capabilities post-deployment, restricting their adaptability. This architectural difference positions modular robots as optimal solutions in dynamic and unpredictable scenarios requiring versatile robotic functions.

Maintenance and Repair: Which Approach Prevails?

Monolithic robots typically require specialized maintenance due to their integrated structure, making repairs complex and time-consuming when individual components fail. Modular robots offer enhanced ease of maintenance and repair as faulty modules can be quickly replaced or reconfigured without disassembling the entire system. This modularity reduces downtime and repair costs, establishing modular robots as the preferable choice for efficient maintenance.

Cost Analysis: Monolithic vs Modular Robots

Monolithic robots generally incur higher upfront costs due to their integrated design and specialized manufacturing processes, while modular robots offer cost advantages through standardized components and scalability. Maintenance expenses tend to be lower for modular robots as individual modules can be replaced or upgraded without overhauling the entire system. Investment in modular robotics supports long-term flexibility and reduced total cost of ownership compared to the fixed architecture of monolithic robots.

Scalability and Customization in Robotic Systems

Monolithic robots exhibit limited scalability and customization due to their fixed architecture, restricting adaptability to evolving tasks or environments. Modular robots, composed of interchangeable units, offer enhanced scalability by enabling easy expansion or reduction of components, facilitating tailored configurations for specific applications. This flexibility in modular robotic systems promotes rapid prototyping and efficient adaptation, meeting diverse operational demands with minimal redesign efforts.

Application Scenarios: When to Choose Each Type

Monolithic robots excel in applications requiring high precision, stability, and durability, such as assembly lines and surgical procedures, where a fixed, robust structure is essential. Modular robots offer unparalleled flexibility and adaptability, making them ideal for exploratory missions, search and rescue operations, and tasks demanding reconfiguration or customization on-the-fly. You should choose monolithic robots for consistent, repetitive tasks, while modular robots suit dynamic environments needing versatile and scalable robotic solutions.

Performance and Efficiency Considerations

Monolithic robots offer high structural rigidity and consistent performance due to their integrated design, which often results in faster task execution and greater precision. Modular robots provide enhanced adaptability and fault tolerance, allowing reconfiguration for varied tasks but may experience reduced efficiency and slower operation due to increased complexity and connection overhead. Performance optimization depends on the application's demand for stability versus flexibility, with monolithic systems excelling in high-speed, precision tasks and modular systems favored for versatile, dynamic environments.

Future Trends in Monolithic and Modular Robot Development

Future trends in monolithic robot development emphasize enhanced precision, durability, and integration of AI-driven control systems, enabling specialized applications in manufacturing and healthcare. Modular robots increasingly adopt reconfigurable architectures with advanced sensor fusion and machine learning capabilities, promoting adaptability and scalability in dynamic environments such as disaster response and space exploration. The convergence of these technologies points toward hybrid robotic systems that combine the robustness of monolithic designs with the flexibility of modular components to address complex, evolving tasks.

Monolithic robot vs Modular robot Infographic

libmatt.com

libmatt.com