PID control uses fixed parameters to maintain system stability by minimizing error based on proportional, integral, and derivative terms, offering simplicity and fast response for linear, time-invariant processes. Model Predictive Control (MPC) employs a dynamic model to predict future system behavior and optimize control actions over a defined horizon, enhancing performance in multivariable systems with constraints and nonlinearities, making it ideal for complex, industrial applications where your control precision and adaptability are critical.

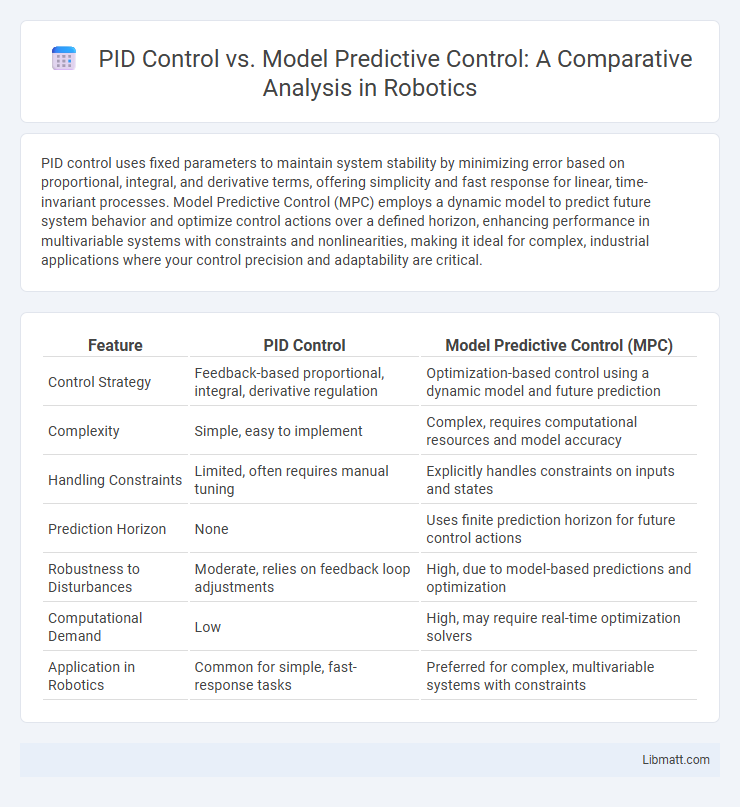

Table of Comparison

| Feature | PID Control | Model Predictive Control (MPC) |

|---|---|---|

| Control Strategy | Feedback-based proportional, integral, derivative regulation | Optimization-based control using a dynamic model and future prediction |

| Complexity | Simple, easy to implement | Complex, requires computational resources and model accuracy |

| Handling Constraints | Limited, often requires manual tuning | Explicitly handles constraints on inputs and states |

| Prediction Horizon | None | Uses finite prediction horizon for future control actions |

| Robustness to Disturbances | Moderate, relies on feedback loop adjustments | High, due to model-based predictions and optimization |

| Computational Demand | Low | High, may require real-time optimization solvers |

| Application in Robotics | Common for simple, fast-response tasks | Preferred for complex, multivariable systems with constraints |

Introduction to PID Control and Model Predictive Control

PID control relies on proportional, integral, and derivative terms to maintain system stability by minimizing error in real-time. Model Predictive Control (MPC) uses a dynamic model to predict future system behavior and optimize control actions over a defined time horizon. PID control excels in simplicity and ease of implementation, while MPC provides advanced handling of multivariable systems and constraints for improved performance.

Fundamental Principles of PID Control

PID control operates on the fundamental principles of proportional, integral, and derivative actions, where the proportional term addresses the present error, the integral term eliminates past accumulated errors, and the derivative term predicts future error trends for improved system stability. This feedback mechanism continuously adjusts control inputs to minimize the difference between the desired setpoint and the actual process variable. PID controllers excel in simplicity and effectiveness for single-input, single-output (SISO) systems with relatively stable dynamics.

Core Concepts of Model Predictive Control

Model Predictive Control (MPC) relies on a dynamic process model to predict future system behavior and optimize control inputs over a finite horizon. Unlike PID control, which uses proportional, integral, and derivative actions based solely on current and past errors, MPC solves a constrained optimization problem at each time step to handle multivariable interactions and constraints explicitly. Your process benefits from MPC's ability to anticipate disturbances and maintain optimal performance within system limits.

Key Differences Between PID and MPC

PID control relies on proportional, integral, and derivative terms to correct errors based on past and present system behavior, making it simpler and computationally less intensive. Model Predictive Control (MPC) uses a dynamic model to predict future system states and optimize control actions over a prediction horizon, allowing it to handle multivariable constraints and system nonlinearities effectively. Unlike PID controllers, MPC can proactively adjust inputs to achieve optimal performance in complex, constrained environments.

Advantages of PID Control Systems

PID control systems offer simplicity and ease of implementation, making them highly reliable for a wide range of industrial applications. Their ability to provide stable and consistent performance with minimal computational resources ensures lower operational costs and faster response times. You benefit from straightforward tuning and robust control even in the presence of process disturbances and parameter variations.

Benefits of Model Predictive Control

Model Predictive Control (MPC) offers significant benefits over PID control by optimizing control actions based on a dynamic model of the process, allowing for multivariable system management and constraint handling. MPC predicts future system behavior, enabling proactive adjustments that improve stability, reduce overshoot, and enhance overall performance in complex processes. Your system gains increased flexibility and efficiency, especially in processes with delays, interactions, or variable constraints where PID controllers typically struggle.

Limitations of PID Control

PID control struggles with handling multivariable systems and constraints, limiting its effectiveness in complex industrial processes. It cannot predict future system behavior, which reduces performance in dynamic environments with time delays or varying setpoints. Model Predictive Control (MPC) addresses these limitations by optimizing control moves based on a predictive model and constraints.

Challenges Faced by Model Predictive Control

Model Predictive Control (MPC) faces challenges such as high computational demand due to solving optimization problems in real-time, which limits its application in fast dynamic systems. The complexity of accurate system modeling and parameter identification significantly impacts MPC performance and robustness. Additionally, constraints handling and the need for tailored tuning require substantial expertise compared to the simplicity of Proportional-Integral-Derivative (PID) control.

Practical Applications: PID vs MPC

PID control is widely used in industrial automation for temperature, speed, and flow regulation due to its simplicity and ease of implementation. Model Predictive Control (MPC) excels in complex multivariable processes such as chemical plants and advanced robotics by optimizing control moves while respecting constraints and future predictions. MPC's computational requirements limit its use in fast, real-time systems where PID remains the preferred method.

Choosing Between PID and Model Predictive Control

Choosing between PID control and Model Predictive Control (MPC) depends on system complexity and performance requirements. PID control suits simple, single-input single-output (SISO) systems with linear dynamics and where ease of implementation and low computational cost are critical. MPC excels in multivariable control problems with constraints, providing optimized control actions by predicting future system behavior using dynamic models.

PID control vs Model predictive control Infographic

libmatt.com

libmatt.com