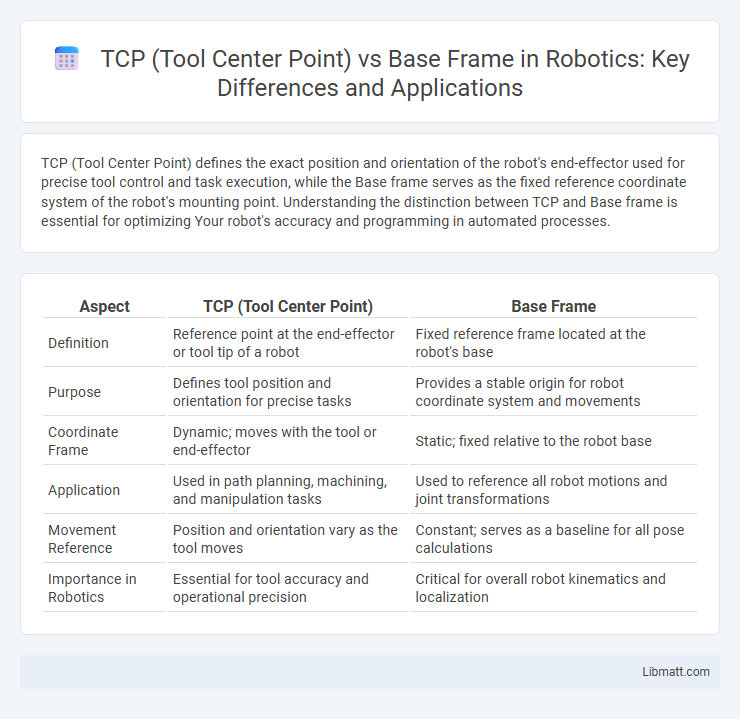

TCP (Tool Center Point) defines the exact position and orientation of the robot's end-effector used for precise tool control and task execution, while the Base frame serves as the fixed reference coordinate system of the robot's mounting point. Understanding the distinction between TCP and Base frame is essential for optimizing Your robot's accuracy and programming in automated processes.

Table of Comparison

| Aspect | TCP (Tool Center Point) | Base Frame |

|---|---|---|

| Definition | Reference point at the end-effector or tool tip of a robot | Fixed reference frame located at the robot's base |

| Purpose | Defines tool position and orientation for precise tasks | Provides a stable origin for robot coordinate system and movements |

| Coordinate Frame | Dynamic; moves with the tool or end-effector | Static; fixed relative to the robot base |

| Application | Used in path planning, machining, and manipulation tasks | Used to reference all robot motions and joint transformations |

| Movement Reference | Position and orientation vary as the tool moves | Constant; serves as a baseline for all pose calculations |

| Importance in Robotics | Essential for tool accuracy and operational precision | Critical for overall robot kinematics and localization |

Introduction to TCP and Base Frame

The Tool Center Point (TCP) is the exact position on a robotic end-effector where task execution occurs, critical for precise motion control and programming. The Base Frame serves as the fixed reference coordinate system for the robot, establishing the origin point for all positional calculations within the robotic workspace. Accurate definition of both TCP and Base Frame enables precise path planning and manipulation in industrial automation environments.

Understanding TCP (Tool Center Point)

The Tool Center Point (TCP) defines the exact position and orientation of a robot's end effector, serving as the precise reference for all motion commands. Unlike the Base frame, which represents the robot's fixed origin in the workspace, the TCP moves dynamically as the tool operates, ensuring accurate control during tasks like welding, painting, or assembly. Optimizing robot programming and path planning hinges on accurately defining the TCP to improve precision and reduce errors.

Defining the Base Frame in Robotics

The Base Frame in robotics serves as the primary coordinate system from which all robot movements and positions are referenced, providing a fixed point of origin for spatial calculations. Unlike the Tool Center Point (TCP), which defines the exact position and orientation of the robot's end effector, the Base Frame remains constant and is essential for accurate path planning and motion control. Understanding your robot's Base Frame ensures precise navigation and coordination within its operating environment.

Key Differences Between TCP and Base Frame

TCP (Tool Center Point) represents the precise location on a robot's end-effector where the tool interacts with the workpiece, crucial for task accuracy and path control. The Base frame refers to the fixed reference coordinate system of the robot, serving as the origin for all positional and orientation measurements. Key differences include that TCP defines the moving point of operation on the tool, whereas the Base frame is a static reference point fixed to the robot's foundation or environment.

Importance of Frames in Robot Programming

Frames in robot programming are critical for defining reference points such as the Tool Center Point (TCP) and Base frame, enabling precise positioning and movement control. The TCP represents the exact point on the end-effector where tasks are executed, essential for accuracy in operations like welding or assembly. The Base frame serves as the robot's fixed coordinate system, providing a stable reference for all movements and ensuring consistency across different tasks and setups.

How TCP and Base Frame Affect Robot Movement

TCP (Tool Center Point) defines the exact point on the robot tool used for precise movement and task execution, directly influencing accuracy and path control. The Base Frame serves as the robot's reference coordinate system, determining how the entire arm moves within the workspace. Your robot's motion dynamics rely heavily on accurate TCP settings and stable Base Frame alignment to ensure precise, repeatable operations.

Calibration Methods for TCP and Base Frame

Calibration methods for the Tool Center Point (TCP) involve precise measurement techniques such as laser trackers, touch probes, and optical sensors to define the exact position and orientation of the tool relative to the robot flange. Base frame calibration uses reference points on the robot's mounting surface or environment, employing methods like external measurement systems or fixture-based alignment to establish the robot's coordinate system accurately. Both calibrations ensure high precision in robotic operations by minimizing positional errors through iterative data collection and adjustment processes.

Application Scenarios: When to Use TCP vs Base Frame

TCP (Tool Center Point) is crucial in robotic applications involving precise end-effector movements, such as welding, painting, and assembly, where accuracy at the tool tip is essential. The base frame is typically used for tasks requiring reference to the robot's fixed mounting position, including navigation, machine tending, or when coordinating multiple robots within a shared workspace. Understanding when to use TCP versus the base frame ensures Your robot operates with optimal spatial awareness and task efficiency.

Common Errors and Troubleshooting

Incorrect calibration of the TCP (Tool Center Point) relative to the Base frame often leads to positioning inaccuracies and unexpected tool paths in robotic operations. Ensuring that your TCP is precisely defined with respect to the Base frame coordinates helps avoid misalignment issues and improves repeatability. Regular verification of TCP parameters against the Base frame and using robot simulation tools can simplify troubleshooting common errors such as offset drift and incorrect orientation.

Future Developments in Robotic Frames

Future developments in robotic frames will enhance the precision of TCP (Tool Center Point) calibration relative to the Base frame, improving robotic accuracy and repeatability in complex tasks. Advances in sensor integration and AI-driven algorithms are expected to enable dynamic adjustment of the Base frame during operation, optimizing real-time control and reducing setup times. Your robotics applications will benefit from increased adaptability and efficiency, driven by these innovations in frame referencing technologies.

TCP (Tool Center Point) vs Base frame Infographic

libmatt.com

libmatt.com