Anvil rubber offers superior shock absorption and durability, making it ideal for heavy-duty stamping applications, while press pad rubber provides enhanced grip and flexibility, suited for lighter, precision tasks. Choosing the right material enhances your equipment's performance and longevity in various industrial processes.

Table of Comparison

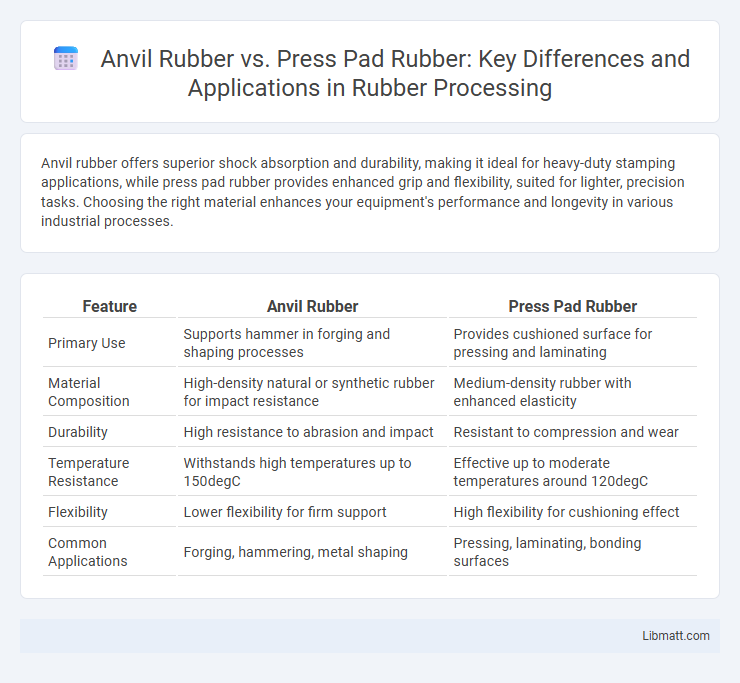

| Feature | Anvil Rubber | Press Pad Rubber |

|---|---|---|

| Primary Use | Supports hammer in forging and shaping processes | Provides cushioned surface for pressing and laminating |

| Material Composition | High-density natural or synthetic rubber for impact resistance | Medium-density rubber with enhanced elasticity |

| Durability | High resistance to abrasion and impact | Resistant to compression and wear |

| Temperature Resistance | Withstands high temperatures up to 150degC | Effective up to moderate temperatures around 120degC |

| Flexibility | Lower flexibility for firm support | High flexibility for cushioning effect |

| Common Applications | Forging, hammering, metal shaping | Pressing, laminating, bonding surfaces |

Introduction to Anvil Rubber and Press Pad Rubber

Anvil rubber and press pad rubber are essential components in industrial printing and manufacturing processes, each designed to provide specific cushioning and durability. Anvil rubber is typically used as a backing material that absorbs impact and ensures smooth operation in letterpress and embossing applications. Press pad rubber offers resilience and precision, making it ideal for supporting materials during high-pressure printing tasks, ensuring consistent quality and protection for your equipment.

Key Differences Between Anvil Rubber and Press Pad Rubber

Anvil rubber typically features higher durability and resistance to impact, making it ideal for withstanding heavy, repetitive hammering in metal forming processes. Press pad rubber is generally softer and more flexible, providing enhanced cushioning and better conformity to uneven surfaces during press operations. The choice between anvil rubber and press pad rubber depends largely on the specific industrial application's need for hardness versus cushioning performance.

Material Composition: Anvil vs Press Pad Rubber

Anvil rubber typically consists of high-density natural or synthetic rubber compounds designed for maximum durability and resistance to impact, while press pad rubber is often made from softer, more pliable materials like nitrile or neoprene to provide cushioning and flexibility. The anvil rubber's composition emphasizes hardness and wear resistance to withstand heavy hammering or pressing forces, whereas press pad rubber prioritizes energy absorption and surface protection during the pressing process. Differences in polymer blends and curing methods greatly influence the mechanical properties and intended industrial applications of each rubber type.

Application Areas: Usage Scenarios Compared

Anvil rubber is primarily used in heavy-duty industrial applications such as impact absorption in forging and stamping presses, where its durability and resistance to deformation are critical. Press pad rubber is designed for lighter tasks, including cushioning and shock absorption in printing presses, assembly lines, and packaging equipment, offering flexibility and vibration dampening. Your choice between anvil rubber and press pad rubber should depend on the operational requirements, with anvil rubber suited for high-impact force environments and press pad rubber ideal for precision and lighter mechanical protection.

Durability and Longevity Analysis

Anvil rubber demonstrates superior durability due to its high-density composition and enhanced resistance to wear, making it ideal for heavy-duty applications requiring long lifespan. Press pad rubber offers moderate longevity, suitable for less intensive use but tends to degrade faster under constant pressure and abrasion. Choosing anvil rubber ensures Your equipment maintains optimal performance longer with reduced maintenance costs.

Performance and Efficiency Comparison

Anvil rubber offers superior durability and impact resistance, making it ideal for high-stress industrial applications, while press pad rubber excels in providing consistent compression and cushioning for smoother pressing operations. The enhanced resilience of anvil rubber reduces maintenance downtime, boosting overall productivity, whereas press pad rubber's elasticity improves energy efficiency by minimizing material deformation. Selecting between anvil rubber and press pad rubber depends on the specific operational demands, balancing performance needs with cost-effective efficiency.

Cost Considerations: Anvil Rubber vs Press Pad Rubber

Anvil rubber typically costs more than press pad rubber due to its higher durability and resistance to impact in industrial applications. Press pad rubber offers a more economical solution for light to medium-duty tasks, balancing performance with affordability. Evaluating the total cost of ownership, including replacement frequency and maintenance, helps determine the most cost-effective choice for specific manufacturing needs.

Maintenance Requirements and Best Practices

Anvil rubber requires regular inspection for wear and tear due to its constant impact in pressing operations, with maintenance involving cleaning and timely replacement to prevent damage to other components. Press pad rubber demands more frequent surface checks and conditioning to maintain optimal grip and prevent slippage during pressing cycles. To ensure your equipment's longevity and performance, implement a routine maintenance schedule focusing on proper cleaning techniques and prompt substitution of worn rubber elements.

User Experiences and Industry Feedback

Users often highlight the Anvil rubber's superior durability and ease of maintenance compared to Press pad rubber, citing longer lifespan and consistent performance under heavy use. Industry feedback emphasizes that Anvil rubber provides better shock absorption and grip, enhancing operational safety and efficiency in various manufacturing environments. Your choice between the two should consider these performance factors and the specific demands of your application for optimal results.

Choosing the Right Rubber: Key Decision Factors

Choosing the right rubber between anvil rubber and press pad rubber depends on factors such as durability, hardness, and compatibility with specific industrial applications. Anvil rubber provides excellent shock absorption and is ideal for high-impact processes, while press pad rubber offers superior compressibility and is suited for uniform pressure distribution. Evaluating the operational environment and load requirements ensures optimal performance and longevity of the selected rubber material.

Anvil rubber vs Press pad rubber Infographic

libmatt.com

libmatt.com