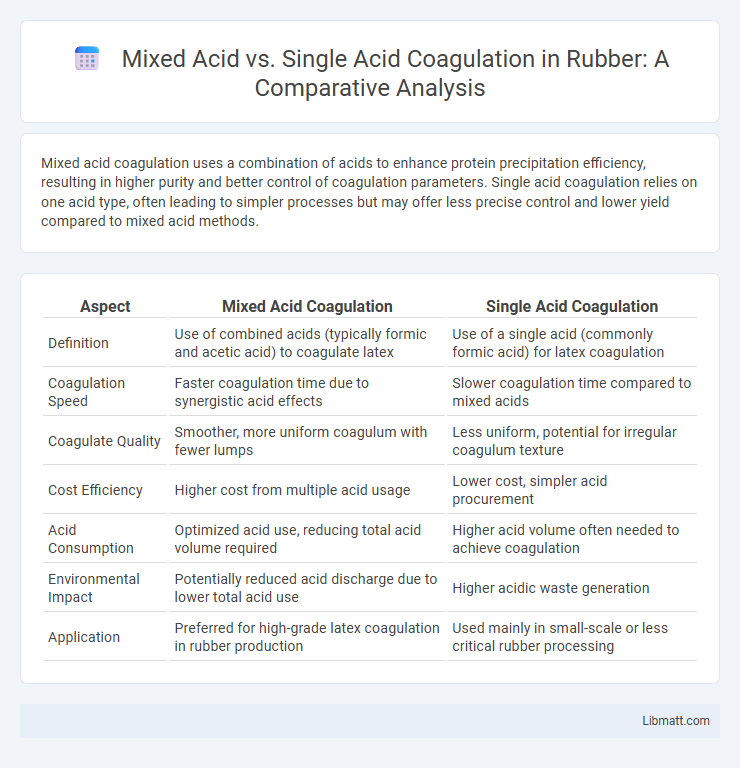

Mixed acid coagulation uses a combination of acids to enhance protein precipitation efficiency, resulting in higher purity and better control of coagulation parameters. Single acid coagulation relies on one acid type, often leading to simpler processes but may offer less precise control and lower yield compared to mixed acid methods.

Table of Comparison

| Aspect | Mixed Acid Coagulation | Single Acid Coagulation |

|---|---|---|

| Definition | Use of combined acids (typically formic and acetic acid) to coagulate latex | Use of a single acid (commonly formic acid) for latex coagulation |

| Coagulation Speed | Faster coagulation time due to synergistic acid effects | Slower coagulation time compared to mixed acids |

| Coagulate Quality | Smoother, more uniform coagulum with fewer lumps | Less uniform, potential for irregular coagulum texture |

| Cost Efficiency | Higher cost from multiple acid usage | Lower cost, simpler acid procurement |

| Acid Consumption | Optimized acid use, reducing total acid volume required | Higher acid volume often needed to achieve coagulation |

| Environmental Impact | Potentially reduced acid discharge due to lower total acid use | Higher acidic waste generation |

| Application | Preferred for high-grade latex coagulation in rubber production | Used mainly in small-scale or less critical rubber processing |

Introduction to Acid Coagulation in Food Processing

Acid coagulation is a critical process in food processing that transforms proteins, primarily in dairy products, by lowering pH to induce curd formation. Mixed acid coagulation uses a combination of organic acids such as lactic and citric acids, enhancing texture and flavor complexity, whereas single acid coagulation typically relies on one acid like acetic acid for a more straightforward coagulation profile. Your choice between mixed and single acid methods will influence the final product's consistency, taste, and application in cheese or tofu production.

Defining Mixed Acid and Single Acid Coagulation

Mixed acid coagulation involves using a combination of acids such as sulfuric acid and hydrochloric acid to achieve more effective protein precipitation, leveraging the synergistic effect of multiple acids. Single acid coagulation, on the other hand, relies on a single type of acid to denature proteins and induce coagulation, typically sulfuric acid or acetic acid. Understanding these methods allows you to select the optimal coagulation process for specific biochemical or industrial applications based on efficiency and target protein characteristics.

Chemical Mechanisms: How Acid Coagulation Works

Mixed acid coagulation involves multiple acids reacting with proteins to destabilize their structure by disrupting ionic bonds and altering the pH, leading to efficient protein precipitation. Single acid coagulation relies on one acid, typically lowering the pH to the isoelectric point of proteins, causing them to aggregate and coagulate through neutralization of charge. The combined chemical mechanisms of acid interaction with protein side chains and altered solubility underpin the coagulation process in both methods.

Common Acids Used in Single Acid Coagulation

Single acid coagulation typically utilizes acids such as hydrochloric acid, sulfuric acid, and acetic acid to induce protein precipitation through pH adjustment. These acids efficiently lower the pH to the isoelectric point of proteins, causing them to aggregate and separate from the solution. Hydrochloric acid is favored for its strong dissociation and rapid action, while acetic acid is commonly used for more controlled coagulation in food and pharmaceutical applications.

Mixed Acid Formulations: Combinations and Ratios

Mixed acid formulations combine sulfuric acid, hydrochloric acid, and nitric acid in specific ratios to enhance coagulation efficiency, often optimizing the balance between acidity and oxidation potential. Typical ratios vary depending on the application, such as 3:1:1 (H2SO4:HCl:HNO3) for metal recovery or wastewater treatment, maximizing metal ion precipitation and reducing sludge volume. These combinations improve process control and adaptability compared to single acid coagulation, which relies solely on one acid type and may require higher acid dosages and longer reaction times.

Impact on Texture and Yield of Dairy Products

Mixed acid coagulation enhances the texture of dairy products by creating a finer, more uniform curd structure, resulting in a creamier mouthfeel compared to single acid coagulation. This method also improves yield by efficiently retaining moisture and proteins during coagulation, preserving more product mass. Your choice between mixed and single acid coagulation directly influences both the sensory quality and economic efficiency of dairy production.

Flavor Profiles: Mixed Acid vs Single Acid Coagulation

Mixed acid coagulation creates complex, layered flavor profiles by combining lactic, acetic, and propionic acids, resulting in a tangy, rich taste with nuanced depth. Single acid coagulation produces a more straightforward flavor, typically dominated by lactic acid, offering a mild and creamy profile that highlights the dairy's natural sweetness. Your choice between these methods impacts the cheese's sensory characteristics, influencing its acidity, aroma, and overall complexity.

Industrial Applications and Processing Considerations

Mixed acid coagulation offers superior versatility in industrial applications such as wastewater treatment, chemical manufacturing, and pharmaceutical processing due to its enhanced ability to target a broader range of contaminants compared to single acid coagulation. Processing considerations for mixed acid systems include careful control of pH levels, reaction times, and acid concentrations to optimize floc formation and minimize corrosion risks, whereas single acid coagulation requires simpler but less adaptable control parameters. Your choice between these methods should weigh factors like treatment complexity, cost, and desired purity to achieve efficient coagulation performance.

Health and Safety Concerns in Acid Coagulation

Mixed acid coagulation involves combining multiple acids, increasing the risk of hazardous reactions, toxic gas emissions, and severe chemical burns, requiring strict handling protocols and personal protective equipment. Single acid coagulation presents lower complexity, reducing potential chemical incompatibilities and improving safety during storage and use, but still demands careful pH monitoring to prevent exposure. Your safe operation depends on understanding the reactivity differences and implementing effective ventilation and emergency response procedures to minimize health risks.

Choosing the Optimal Coagulation Method for Your Product

Selecting the optimal coagulation method hinges on the product's chemical composition and desired purity level. Mixed acid coagulation offers enhanced efficiency and faster precipitation for complex formulations, while single acid coagulation provides simplicity and cost-effectiveness for products with straightforward acid-base reactions. Your decision should weigh factors like reaction speed, product quality, and operational costs to ensure the ideal coagulation process.

Mixed acid vs Single acid coagulation Infographic

libmatt.com

libmatt.com