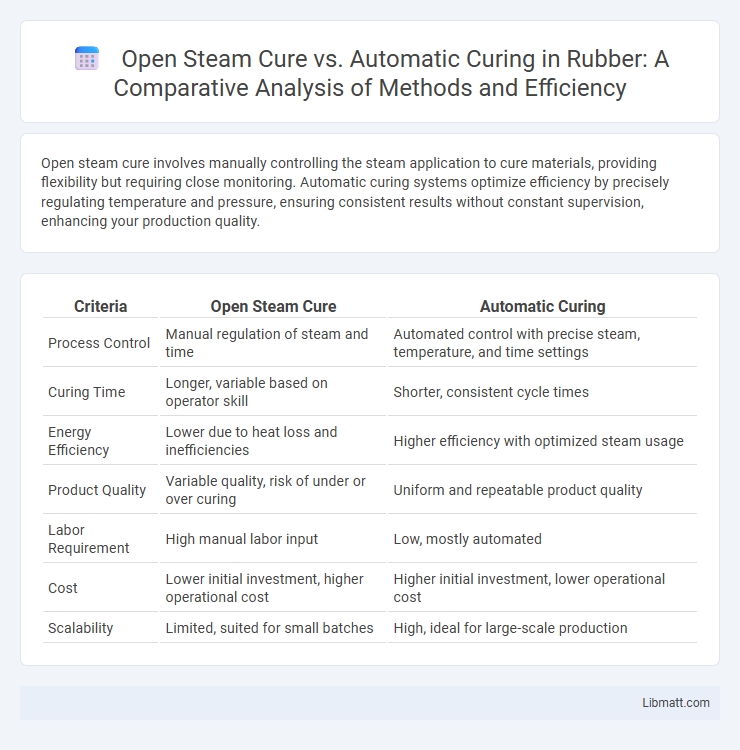

Open steam cure involves manually controlling the steam application to cure materials, providing flexibility but requiring close monitoring. Automatic curing systems optimize efficiency by precisely regulating temperature and pressure, ensuring consistent results without constant supervision, enhancing your production quality.

Table of Comparison

| Criteria | Open Steam Cure | Automatic Curing |

|---|---|---|

| Process Control | Manual regulation of steam and time | Automated control with precise steam, temperature, and time settings |

| Curing Time | Longer, variable based on operator skill | Shorter, consistent cycle times |

| Energy Efficiency | Lower due to heat loss and inefficiencies | Higher efficiency with optimized steam usage |

| Product Quality | Variable quality, risk of under or over curing | Uniform and repeatable product quality |

| Labor Requirement | High manual labor input | Low, mostly automated |

| Cost | Lower initial investment, higher operational cost | Higher initial investment, lower operational cost |

| Scalability | Limited, suited for small batches | High, ideal for large-scale production |

Introduction to Concrete Curing Methods

Open steam cure and automatic curing represent two critical concrete curing methods used to enhance strength and durability. Open steam cure involves exposing concrete to steam in open environments, accelerating hydration and improving early strength, while automatic curing employs controlled, programmable equipment to maintain optimal moisture and temperature conditions consistently. Both methods aim to optimize concrete's microstructure, reduce cracking, and ensure long-term performance in various construction applications.

Overview of Open Steam Cure

Open Steam Cure is a traditional curing method that utilizes direct exposure of materials to steam within an open environment, facilitating uniform heat distribution and rapid moisture absorption. This process enhances the strength and durability of materials such as concrete and rubber by promoting efficient hydration and vulcanization. Your choice of Open Steam Cure ensures a cost-effective solution with controlled temperature and humidity, although it may require more labor and monitoring compared to Automatic Curing systems.

What is Automatic Curing?

Automatic curing is a fully controlled process that uses precise temperature, humidity, and time settings to consistently cure materials like leather or meat without manual intervention. This method enhances product quality by ensuring uniformity and reducing the risk of errors compared to open steam cure, which relies on less controlled steam exposure. Your production efficiency improves as automatic curing systems optimize resource use and maintain consistent conditions throughout the curing cycle.

Key Differences Between Open Steam Cure and Automatic Curing

Open steam cure involves manual control over temperature, pressure, and curing time, allowing operators to adjust parameters based on real-time observations. Automatic curing uses pre-set programs and sensors to maintain consistent conditions, reducing human error and improving repeatability. Your choice depends on whether flexibility or process consistency is a higher priority for your production needs.

Efficiency and Speed of Each Method

Open steam cure offers quicker initial heating due to direct exposure to steam, making it ideal for smaller batches or specific applications requiring rapid temperature rise. Automatic curing systems enhance overall efficiency by providing consistent temperature control and uniform curing conditions, reducing human error and ensuring repeatable results in large-scale production. While open steam cure excels in speed for short cycles, automatic curing optimizes throughput and product quality through precision and automation in continuous processes.

Impact on Concrete Strength and Durability

Open steam curing enhances early concrete strength by accelerating hydration but can cause surface drying and thermal gradients that reduce long-term durability. Automatic curing systems precisely control temperature and moisture, promoting uniform strength development and improving concrete's resistance to cracking and environmental damage. Your choice between methods affects the balance between rapid strength gain and sustained durability in concrete structures.

Energy Consumption and Cost Analysis

Open steam cure systems typically consume more energy due to heat loss and longer curing times, resulting in higher operational costs. Automatic curing processes optimize energy use with precise temperature control and shorter cycles, lowering overall consumption and expenses. Your choice between the two methods impacts both energy efficiency and cost-effectiveness in industrial applications.

Quality Control in Curing Processes

Open Steam Cure offers greater manual oversight, allowing operators to closely monitor temperature and moisture levels for precise quality control. Automatic Curing systems utilize advanced sensors and real-time data analytics to maintain consistent curing conditions, minimizing human error and ensuring uniform product quality. Your choice depends on the need for hands-on adjustments versus automated consistency in curing processes.

Environmental and Safety Considerations

Open steam cure processes emit higher levels of steam and volatile organic compounds (VOCs), increasing environmental pollution and workplace hazards compared to automatic curing systems. Automatic curing uses enclosed chambers with precise temperature and pressure control, reducing emissions and minimizing workers' exposure to harmful fumes. Enhanced insulation and automation in automatic curing lower energy consumption and improve overall safety standards in industrial environments.

Choosing the Right Curing Method for Your Project

Selecting the appropriate curing method depends on factors like project size, material type, and desired curing speed. Open steam cure offers cost-efficiency and ease for smaller or less complex applications, while automatic curing provides precision control and uniformity ideal for large-scale or high-performance projects. Evaluating specific project requirements ensures optimal durability, strength, and quality in the final product.

Open Steam Cure vs Automatic Curing Infographic

libmatt.com

libmatt.com