High abrasion rubber offers superior resistance to wear and tear, making it ideal for applications requiring durability against friction and surface damage. High tensile rubber provides enhanced strength and elasticity, ensuring your materials can withstand heavy loads and stretching without breaking.

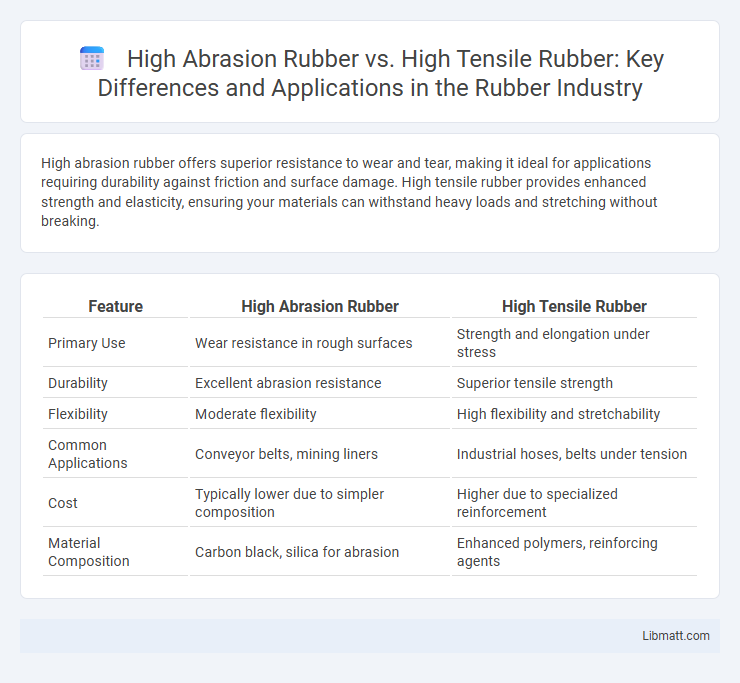

Table of Comparison

| Feature | High Abrasion Rubber | High Tensile Rubber |

|---|---|---|

| Primary Use | Wear resistance in rough surfaces | Strength and elongation under stress |

| Durability | Excellent abrasion resistance | Superior tensile strength |

| Flexibility | Moderate flexibility | High flexibility and stretchability |

| Common Applications | Conveyor belts, mining liners | Industrial hoses, belts under tension |

| Cost | Typically lower due to simpler composition | Higher due to specialized reinforcement |

| Material Composition | Carbon black, silica for abrasion | Enhanced polymers, reinforcing agents |

Introduction to High Abrasion Rubber and High Tensile Rubber

High Abrasion Rubber is engineered for exceptional resistance against wear and tear, making it ideal for applications involving heavy friction and abrasive environments. High Tensile Rubber prioritizes tensile strength and elasticity, providing superior durability and flexibility under significant stretching or tension. Your selection between these elastomers depends on whether durability against surface wear or strength under tension is the critical requirement.

Key Properties of High Abrasion Rubber

High abrasion rubber is engineered for exceptional wear resistance, making it ideal for applications exposed to continuous friction and abrasion. It typically features a higher hardness and enhanced resistance to cutting, chipping, and tearing compared to high tensile rubber. These key properties ensure durability and longevity in demanding industrial environments such as mining, construction, and conveyor belt systems.

Key Properties of High Tensile Rubber

High tensile rubber features exceptional strength and elasticity, making it ideal for applications requiring resistance to tearing and stretching under heavy loads. Its molecular structure provides superior tensile strength, ensuring durability and long service life in demanding environments. You benefit from its ability to maintain performance under stress, reducing maintenance and replacement costs.

Composition and Material Differences

High abrasion rubber typically contains higher carbon black concentrations and specialized fillers to enhance durability and resistance to wear, making it ideal for environments with intense friction and surface contact. High tensile rubber incorporates stronger polymer chains and reinforced additives like silica or aramid fibers to improve tensile strength and elasticity, ensuring it withstands significant stretching and mechanical stress. Your choice between these materials should depend on whether abrasion resistance or tensile performance is crucial for your application.

Performance in Industrial Applications

High abrasion rubber excels in industrial applications requiring exceptional wear resistance, making it ideal for conveyor belts, liners, and seals exposed to constant friction and abrasive materials. High tensile rubber offers superior strength and elasticity, providing enhanced durability under heavy loads and dynamic stresses, suitable for tires, vibration dampers, and heavy-duty hoses. Both materials improve operational efficiency by reducing downtime and maintenance costs, but selecting the appropriate type depends on whether wear resistance or tensile strength is the primary performance criterion.

Durability Comparison: Abrasion vs. Tensile Strength

High Abrasion Rubber excels in resisting surface wear, making it ideal for applications where material degradation from friction is critical. High Tensile Rubber offers superior tensile strength, providing enhanced resistance to stretching and breaking under load. Your choice should depend on whether durability against abrasion or tensile stress is more crucial for your specific use case.

Cost Considerations and Economic Impact

High Abrasion Rubber typically costs more upfront due to its enhanced durability and resistance to wear, which can lower maintenance expenses and extend equipment lifespan. High Tensile Rubber often offers a more affordable initial investment but may require more frequent replacements, increasing long-term operational costs. Evaluating your specific application's abrasion versus tensile demands will help determine which material maximizes economic efficiency.

Best Use Cases for High Abrasion Rubber

High Abrasion Rubber excels in environments with intense friction and wear, such as conveyor belts, mining equipment, and heavy-duty industrial machinery, where durability against surface damage is critical. Its enhanced resistance to cuts, tears, and abrasion makes it ideal for applications requiring prolonged service life under harsh mechanical stress. Choosing High Abrasion Rubber for your equipment ensures improved performance and reduced downtime in abrasive conditions.

Ideal Applications for High Tensile Rubber

High tensile rubber is ideal for applications requiring exceptional strength and resistance to mechanical stress, such as conveyor belts, heavy-duty hoses, and industrial tires. Its superior durability under high tension makes it suitable for environments with constant stretching or heavy loads. When selecting materials for your project, high tensile rubber ensures longevity and reliability in demanding mechanical conditions.

Choosing the Right Rubber: Factors to Consider

When choosing between high abrasion rubber and high tensile rubber, consider the specific application's wear resistance and strength requirements. High abrasion rubber excels in environments with constant friction and surface contact, while high tensile rubber provides superior durability under heavy loads and stretching forces. Assessing your operational conditions and desired longevity will help you select the ideal rubber type for optimal performance.

High Abrasion Rubber vs High Tensile Rubber Infographic

libmatt.com

libmatt.com