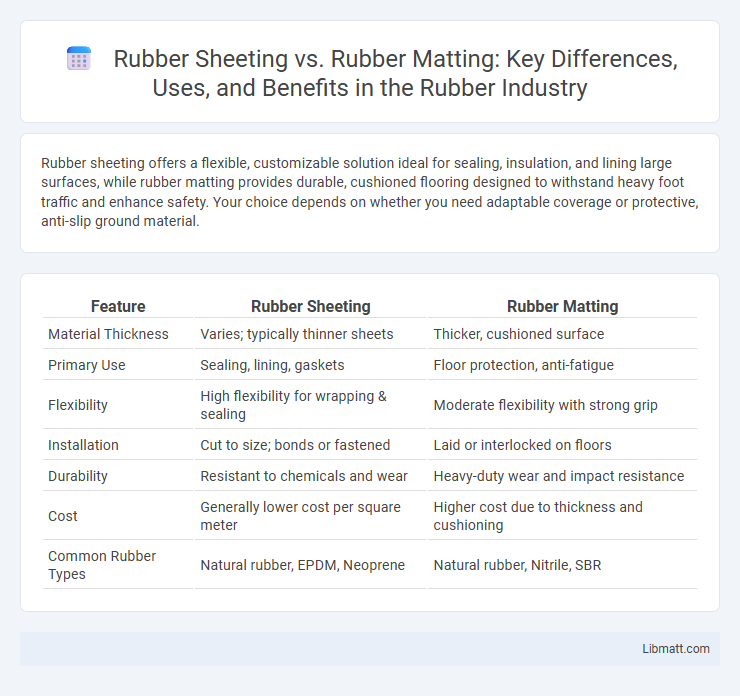

Rubber sheeting offers a flexible, customizable solution ideal for sealing, insulation, and lining large surfaces, while rubber matting provides durable, cushioned flooring designed to withstand heavy foot traffic and enhance safety. Your choice depends on whether you need adaptable coverage or protective, anti-slip ground material.

Table of Comparison

| Feature | Rubber Sheeting | Rubber Matting |

|---|---|---|

| Material Thickness | Varies; typically thinner sheets | Thicker, cushioned surface |

| Primary Use | Sealing, lining, gaskets | Floor protection, anti-fatigue |

| Flexibility | High flexibility for wrapping & sealing | Moderate flexibility with strong grip |

| Installation | Cut to size; bonds or fastened | Laid or interlocked on floors |

| Durability | Resistant to chemicals and wear | Heavy-duty wear and impact resistance |

| Cost | Generally lower cost per square meter | Higher cost due to thickness and cushioning |

| Common Rubber Types | Natural rubber, EPDM, Neoprene | Natural rubber, Nitrile, SBR |

Introduction to Rubber Sheeting and Rubber Matting

Rubber sheeting consists of thin, flexible sheets of natural or synthetic rubber ideal for sealing, insulation, and protection against abrasion and chemicals in industrial applications. Rubber matting features thicker, durable rubber products designed to provide cushioning, anti-slip surfaces, and impact absorption in workplaces, gyms, and outdoor environments. Both materials offer essential benefits in safety and durability but serve distinct functional purposes based on thickness and application requirements.

Key Differences Between Rubber Sheeting and Rubber Matting

Rubber sheeting is typically a thin, flexible material used for sealing, gasketing, or lining applications, whereas rubber matting is thicker and designed for impact absorption, anti-slip surfaces, and ergonomic flooring. Sheeting often comes in customizable widths and thicknesses for industrial sealing purposes, while matting features textured surfaces to enhance grip and durability in high-traffic or wet areas. Rubber matting's focus on cushioning and safety contrasts with rubber sheeting's role in protection and containment.

Material Composition and Manufacturing Processes

Rubber sheeting typically consists of synthetic or natural rubber compounds formulated for flexibility and durability, produced through processes such as calendaring or extrusion to create thin, uniform sheets. Rubber matting is often manufactured using similar rubber compounds but is thicker and may incorporate additional components like fabric reinforcement, created by molding or pressing to enhance cushioning and wear resistance. The material composition in sheeting prioritizes elasticity and smoothness, while matting focuses on robustness and surface texture for slip resistance.

Common Applications of Rubber Sheeting

Rubber sheeting is widely used in industrial sealing, gaskets, and protective linings due to its customizable thickness and resistance to chemicals, oils, and abrasion, making it ideal for factory floors and machinery protection. It also serves in automotive applications for vibration dampening and insulation, as well as in roofing and waterproofing projects where durability is essential. Your choice of rubber sheeting can enhance equipment longevity and safety by providing reliable sealing and cushioning across various commercial and manufacturing environments.

Popular Uses of Rubber Matting

Rubber matting is widely used in industrial and commercial settings for its durability and slip-resistant properties, making it ideal for gym floors, workshop areas, and entryways. It provides excellent cushioning and impact absorption, protecting both equipment and personnel from fatigue and injury. If you're seeking enhanced safety and comfort in high-traffic zones, rubber matting is a practical choice over rubber sheeting.

Durability and Performance Comparison

Rubber sheeting generally offers superior durability in industrial applications due to its uniform thickness and resistance to abrasion, chemicals, and temperature fluctuations compared to rubber matting. Rubber matting provides enhanced performance in impact absorption and slip resistance, making it ideal for safety flooring and anti-fatigue purposes. Both materials excel in resilience, but the choice depends on specific environmental demands and functional requirements.

Installation and Maintenance Requirements

Rubber sheeting offers a seamless installation process with fewer joints, reducing potential points of wear and making it quicker to install in large areas. Rubber matting typically involves individual pieces that require precise alignment and securing, leading to longer installation times and potential gaps. Maintenance for rubber sheeting is generally simpler due to its continuous surface, while rubber matting may need more frequent inspections and cleaning to prevent debris accumulation in seams.

Safety, Comfort, and Slip Resistance

Rubber sheeting offers superior slip resistance thanks to its smooth, continuous surface that prevents tripping hazards, making it ideal for maintaining safety in high-traffic areas. Rubber matting provides enhanced comfort through its cushioned texture, reducing fatigue for users standing for extended periods. When choosing between them, consider your specific needs for safety and comfort, as rubber sheeting excels in seamless slip resistance, while matting enhances ergonomic support.

Cost Analysis: Rubber Sheeting vs Rubber Matting

Rubber sheeting generally offers a lower cost per square foot compared to rubber matting, making it a budget-friendly option for large surface coverage. Rubber matting, while typically more expensive, provides enhanced durability and shock absorption ideal for high-impact or high-traffic areas. Your choice between rubber sheeting and rubber matting should weigh upfront costs against long-term performance and maintenance expenses.

How to Choose the Right Rubber Solution for Your Needs

Rubber sheeting offers customizable thickness and size, ideal for sealing, insulation, and industrial applications requiring flexibility and precise fitting. Rubber matting provides durable, impact-resistant surfaces suited for anti-fatigue flooring, safety, and heavy-traffic areas demanding slip resistance and cushioning. Assess whether your priority is tailored dimensions or resilient, ready-to-use mats to select the best rubber solution for operational efficiency and safety.

Rubber sheeting vs Rubber matting Infographic

libmatt.com

libmatt.com