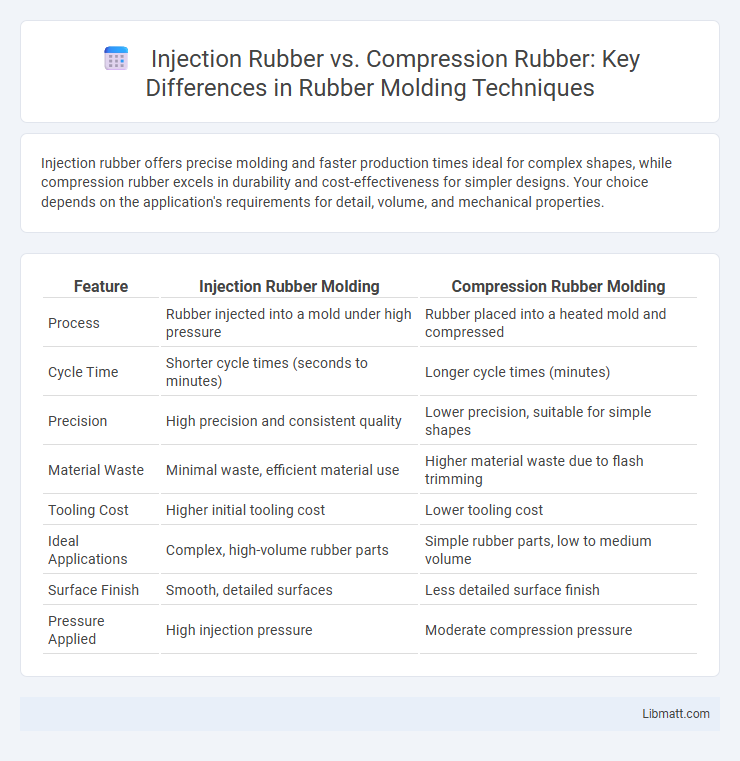

Injection rubber offers precise molding and faster production times ideal for complex shapes, while compression rubber excels in durability and cost-effectiveness for simpler designs. Your choice depends on the application's requirements for detail, volume, and mechanical properties.

Table of Comparison

| Feature | Injection Rubber Molding | Compression Rubber Molding |

|---|---|---|

| Process | Rubber injected into a mold under high pressure | Rubber placed into a heated mold and compressed |

| Cycle Time | Shorter cycle times (seconds to minutes) | Longer cycle times (minutes) |

| Precision | High precision and consistent quality | Lower precision, suitable for simple shapes |

| Material Waste | Minimal waste, efficient material use | Higher material waste due to flash trimming |

| Tooling Cost | Higher initial tooling cost | Lower tooling cost |

| Ideal Applications | Complex, high-volume rubber parts | Simple rubber parts, low to medium volume |

| Surface Finish | Smooth, detailed surfaces | Less detailed surface finish |

| Pressure Applied | High injection pressure | Moderate compression pressure |

Introduction to Injection and Compression Rubber

Injection rubber involves injecting heated rubber into a mold under high pressure, ensuring uniform filling and precise shapes suitable for complex designs. Compression rubber consists of placing pre-measured rubber compounds directly into an open mold cavity, followed by applying heat and pressure to cure the material, ideal for simple, durable parts. Understanding these methods helps you select the appropriate process based on production volume, complexity, and cost efficiency.

Manufacturing Process Overview

Injection rubber involves a process where heated rubber is injected into a mold cavity under high pressure, ensuring precise filling and faster cycle times ideal for intricate designs. Compression rubber molding requires placing a pre-measured amount of rubber into an open mold, then applying heat and pressure to shape it, which suits larger parts and materials with higher viscosity. Your choice between these methods depends on factors like production volume, part complexity, and material properties.

Material Compatibility and Selection

Injection rubber offers precise molding suitable for complex shapes, making it compatible with a wide range of synthetic materials like silicone and nitrile, while compression rubber excels in handling natural and EPDM rubbers that thrive under heat and pressure. Material selection depends on your specific application needs, including chemical resistance, flexibility, and temperature tolerance. Choosing the right rubber type ensures durability and optimal performance in environments ranging from automotive seals to medical devices.

Production Speed and Efficiency

Injection rubber molding offers faster production cycles due to continuous material injection and automated processes, leading to higher efficiency for large-volume outputs. Compression rubber molding involves slower cycle times with manual loading and pressing, making it less efficient for mass production but suitable for simpler, low-volume runs. The choice between injection and compression rubber depends on balancing production speed, complexity, and batch size.

Cost Comparison

Injection rubber molding typically offers lower per-unit costs for high-volume production due to faster cycle times and automated processes, making it more cost-effective for large-scale manufacturing. Compression rubber molding incurs higher initial tooling costs and longer cycle times, which increase expenses in low to medium volume runs but may be more affordable for small batch or prototype production. Evaluating production volume and complexity is essential to determine the most economical choice between injection and compression rubber molding.

Precision and Tolerances

Injection rubber molding offers superior precision and tighter tolerances due to the controlled injection of material into complex molds, allowing for consistent replication of intricate designs. Compression rubber molding, while effective for simpler shapes, generally results in wider tolerances and less detailed accuracy because the material is compressed rather than injected, leading to variable mold fill and shrinkage. Industries demanding high precision, such as automotive and aerospace, often prefer injection molding for its reliable tight tolerances and repeatability.

Design Flexibility

Injection rubber offers greater design flexibility compared to compression rubber due to its ability to fill complex molds with intricate details and varying thicknesses, enabling the production of precise and consistent parts. Compression rubber, while effective for simpler shapes, often limits design complexity because it relies on pressure to form the material, which can lead to material flow challenges in detailed sections. Your choice of injection rubber supports more innovative and customized designs, especially for applications requiring tight tolerances and fine features.

Quality and Performance Consistency

Injection rubber offers superior quality and performance consistency due to precise mold filling under controlled pressure and temperature, resulting in uniform density and fewer defects. Compression rubber can vary in quality because it relies on manual loading and curing, which may cause inconsistencies in mechanical properties and surface finish. You receive better repeatability and higher reliability from injection rubber parts, especially in high-volume production scenarios.

Typical Applications

Injection rubber is commonly used in applications requiring intricate mold shapes and tight tolerances, such as automotive seals, medical device components, and electronic gaskets. Compression rubber suits high-volume production of simple parts like automotive tires, shoe soles, and industrial pads due to its cost-effective process and durability. Your choice depends on the complexity and volume of the part, with injection molding preferred for detailed designs and compression molding ideal for robust, straightforward components.

Choosing the Right Method for Your Project

Injection rubber molding offers precise control over complex shapes and high-volume production efficiency, making it ideal for projects requiring intricate designs and consistency. Compression rubber molding excels in durability and cost-effectiveness for large, simple parts or small production runs where minimal tool investment is preferred. Evaluating project complexity, volume, and budget ensures selecting the optimal rubber molding method that balances quality with manufacturing needs.

Injection rubber vs Compression rubber Infographic

libmatt.com

libmatt.com