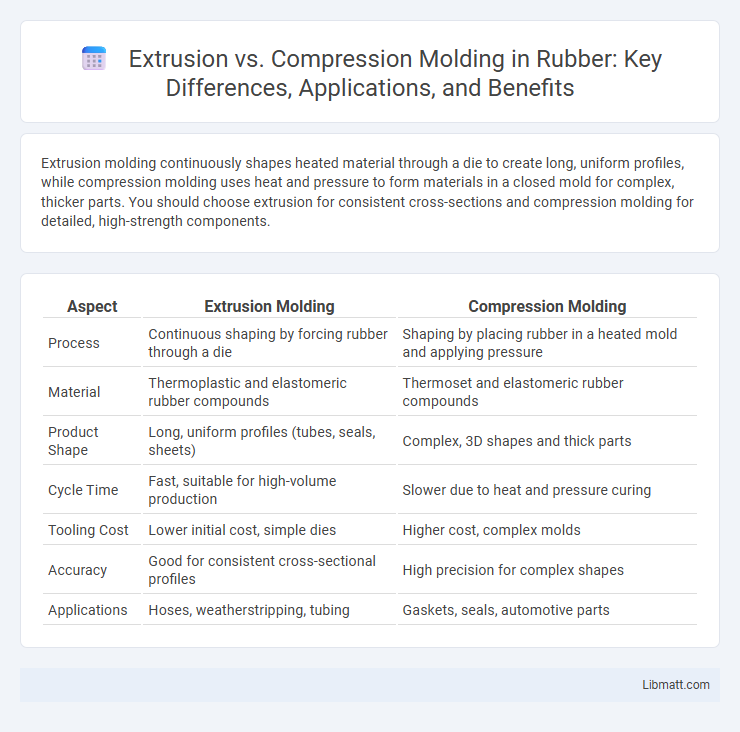

Extrusion molding continuously shapes heated material through a die to create long, uniform profiles, while compression molding uses heat and pressure to form materials in a closed mold for complex, thicker parts. You should choose extrusion for consistent cross-sections and compression molding for detailed, high-strength components.

Table of Comparison

| Aspect | Extrusion Molding | Compression Molding |

|---|---|---|

| Process | Continuous shaping by forcing rubber through a die | Shaping by placing rubber in a heated mold and applying pressure |

| Material | Thermoplastic and elastomeric rubber compounds | Thermoset and elastomeric rubber compounds |

| Product Shape | Long, uniform profiles (tubes, seals, sheets) | Complex, 3D shapes and thick parts |

| Cycle Time | Fast, suitable for high-volume production | Slower due to heat and pressure curing |

| Tooling Cost | Lower initial cost, simple dies | Higher cost, complex molds |

| Accuracy | Good for consistent cross-sectional profiles | High precision for complex shapes |

| Applications | Hoses, weatherstripping, tubing | Gaskets, seals, automotive parts |

Introduction to Extrusion and Compression Molding

Extrusion molding involves forcing molten material through a die to create continuous shapes such as pipes, sheets, or profiles, optimizing production of uniform cross-sectional designs. Compression molding uses preheated polymer blanks placed into a heated mold cavity where pressure shapes the material, ideal for producing complex, high-strength parts with detailed surface finishes. Both methods are essential in manufacturing, with extrusion favored for continuous, long-length products and compression molding preferred for intricate, precision components.

Overview of the Extrusion Process

Extrusion is a continuous manufacturing process where raw plastic material is melted and forced through a shaped die to create long, consistent profiles such as tubing, sheets, or films. The process efficiently produces uniform cross-sectional products with excellent surface finish and dimensional accuracy. Your choice of extrusion allows for high-volume production with minimal waste and easy customization of shapes.

Overview of Compression Molding

Compression molding involves placing a pre-measured amount of thermosetting polymer or composite material into an open, heated mold cavity, followed by closing the mold and applying pressure to shape and cure the part. This process is ideal for producing large, intricate components with high strength and excellent surface finishes, commonly used in automotive and aerospace industries. The key advantages include low material waste, good dimensional control, and suitability for manufacturing high-volume production runs of durable, heat-resistant parts.

Key Differences Between Extrusion and Compression Molding

Extrusion molding continuously shapes molten material by forcing it through a die, producing uniform cross-sectional profiles like pipes or sheets, while compression molding involves placing material into a heated mold cavity and applying pressure to form complex, three-dimensional parts with high precision. Extrusion is ideal for creating long, consistent shapes with rapid production rates, whereas compression molding excels in producing large, intricate components with superior mechanical properties. Your choice depends on the desired product geometry, material type, and production volume requirements.

Material Compatibility in Each Process

Extrusion molding efficiently processes thermoplastic materials such as polyethylene, polypropylene, and PVC due to their ability to be continuously melted and formed through a die. Compression molding primarily suits thermosetting plastics like phenolics, epoxies, and silicones, which cure and harden under heat and pressure. Material compatibility depends on thermal properties and viscosity, making extrusion ideal for flexible, melt-processable polymers and compression molding optimal for heat-activated, rigid composites.

Applications: Where Each Method Excels

Extrusion molding excels in producing continuous profiles such as pipes, tubes, and sheets commonly used in construction, packaging, and automotive industries. Compression molding is ideal for manufacturing complex, high-strength parts like automotive components, electrical insulators, and aerospace panels due to its ability to handle thermoset materials and thick sections. Your choice depends on whether you need continuous shapes with uniform cross-sections (extrusion) or precise, durable parts with intricate designs (compression molding).

Advantages of Extrusion

Extrusion offers continuous production with high efficiency, making it ideal for manufacturing long, uniform profiles like pipes, films, and sheets. Your cost savings increase due to minimal material waste and reduced labor requirements compared to compression molding. This process also provides superior control over product dimensions and surface finish, enhancing quality consistency across large volumes.

Advantages of Compression Molding

Compression molding offers superior control over part thickness and material distribution, resulting in high-strength, durable components ideal for automotive and aerospace industries. The process allows the use of a wide range of thermosetting polymers and composites, enhancing heat resistance and mechanical performance. You benefit from lower tooling costs and reduced material waste compared to extrusion, making compression molding a cost-effective option for producing complex, high-quality parts.

Limitations and Challenges of Both Methods

Extrusion molding faces limitations such as difficulty in producing complex cross-sectional shapes and sensitivity to material viscosity, which can affect product consistency. Compression molding challenges include longer cycle times and less suitability for intricate designs due to limited mold flexibility, resulting in potential dimensional inaccuracies. Your choice between these methods should consider factors like production volume, design complexity, and material behavior under heat and pressure.

Choosing the Right Process for Your Project

Selecting between extrusion and compression molding depends on the project's complexity, material type, and production volume. Extrusion suits continuous profiles with uniform cross-sections, ideal for plastic pipes, sheets, and films, offering high-speed production and material efficiency. Compression molding excels in shaping intricate, high-strength thermoset parts like automotive components, providing superior mechanical properties and dimensional accuracy for medium to large production runs.

Extrusion vs Compression molding Infographic

libmatt.com

libmatt.com