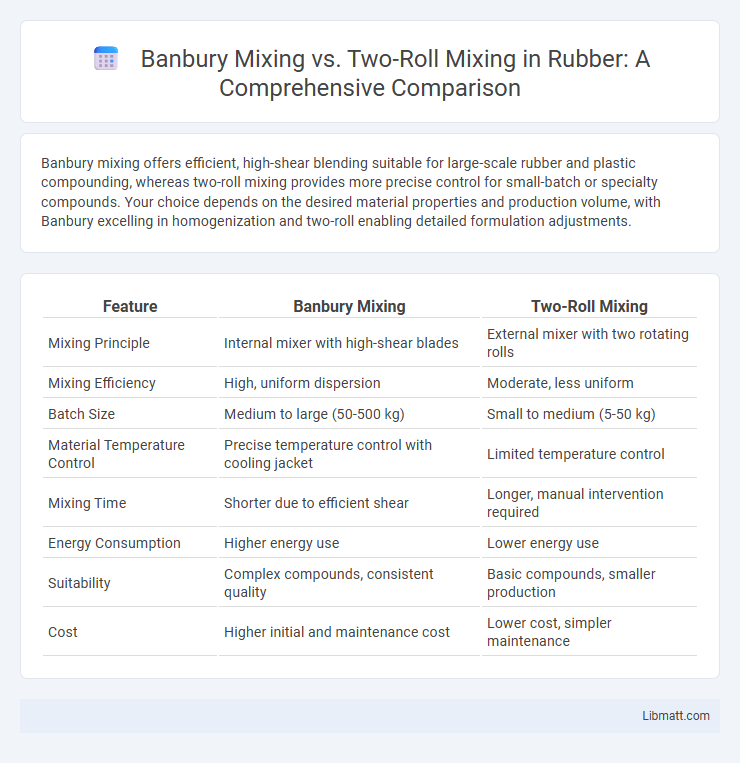

Banbury mixing offers efficient, high-shear blending suitable for large-scale rubber and plastic compounding, whereas two-roll mixing provides more precise control for small-batch or specialty compounds. Your choice depends on the desired material properties and production volume, with Banbury excelling in homogenization and two-roll enabling detailed formulation adjustments.

Table of Comparison

| Feature | Banbury Mixing | Two-Roll Mixing |

|---|---|---|

| Mixing Principle | Internal mixer with high-shear blades | External mixer with two rotating rolls |

| Mixing Efficiency | High, uniform dispersion | Moderate, less uniform |

| Batch Size | Medium to large (50-500 kg) | Small to medium (5-50 kg) |

| Material Temperature Control | Precise temperature control with cooling jacket | Limited temperature control |

| Mixing Time | Shorter due to efficient shear | Longer, manual intervention required |

| Energy Consumption | Higher energy use | Lower energy use |

| Suitability | Complex compounds, consistent quality | Basic compounds, smaller production |

| Cost | Higher initial and maintenance cost | Lower cost, simpler maintenance |

Introduction to Rubber Mixing Methods

Banbury mixing and two-roll mixing are essential rubber mixing methods that enhance compound uniformity and performance. Banbury mixers provide intensive, controlled mixing with high shear and temperature control, ideal for large-scale production and complex compounds. Your choice between these methods should consider factors like batch size, compound complexity, and mixing precision to optimize rubber manufacturing efficiency.

Overview of Banbury Mixing

Banbury mixing utilizes a high-intensity internal mixer with rotors enclosed within a robust chamber, enabling efficient and uniform blending of polymers, fillers, and additives. This process generates intense shear and heat, allowing rapid dispersion of materials and improved compound consistency. Your production benefits from precise control of temperature and mixing time, making Banbury mixing ideal for rubber, plastics, and thermoplastic elastomer processing.

Understanding Two-Roll Mixing

Two-roll mixing uses two counter-rotating metal rollers to blend rubber compounds and additives, providing efficient shear and dispersive mixing for uniform material consistency. The adjustable gap between rollers controls the thickness and extent of mixing, which is critical for processing viscosity and filler dispersion. Compared to Banbury mixing, two-roll mixing offers greater control over material flow and temperature, making it ideal for smaller batch sizes and specialty compounds.

Key Differences Between Banbury and Two-Roll Mixing

Banbury mixing employs a closed, high-torque mixer designed for uniform rubber or plastic compounding, offering superior dispersive mixing for complex formulations. Two-roll mixing uses open rolls to shear and blend materials, providing better temperature control and easier ingredient addition but less homogenization. Key differences include batch size capacity, with Banbury allowing larger volumes, and mixing consistency, where Banbury ensures more uniform dispersion compared to the variable output of two-roll mills.

Process Efficiency Comparison

Banbury mixing achieves higher process efficiency than Two-roll mixing by offering superior dispersion and uniformity of materials within a shorter cycle time, typically 3 to 7 minutes compared to 10 to 15 minutes for Two-roll milling. Banbury mixers utilize enclosed chambers with powerful rotors, ensuring consistent shearing forces and reducing waste through precise temperature control and rapid mixing action. Two-roll mixers, while cost-effective for small batches, lack automated control systems and require manual adjustments, leading to variability in product quality and longer processing times.

Material Consistency and Dispersion

Banbury mixing ensures superior material consistency through high shear and intense kneading action, resulting in uniform dispersion of fillers and additives in rubber compounds. Two-roll mixing offers less shear, leading to slower and sometimes uneven dispersion, which can cause variations in material properties. The closed, enclosed environment of Banbury mixers minimizes contamination and improves batch-to-batch consistency compared to open two-roll mills.

Energy Consumption and Cost Analysis

Banbury mixers typically consume more energy per batch due to higher shear forces but enable faster mixing times, improving throughput efficiency. Two-roll mills have lower energy consumption overall but require longer mixing periods, impacting labor costs and production speed. Cost analysis reveals Banbury mixers incur higher initial investment and maintenance expenses, while two-roll mills offer lower capital costs but increased operational time leads to higher indirect expenses.

Application Suitability for Each Method

Banbury mixers excel in applications requiring high shear and intensive mixing of rubber and plastics, making them ideal for dense compounds and recoating processes. Two-roll mills are better suited for softer materials and thin sheets, offering precise control for blending and calendaring in industries like rubber and tire manufacturing. Your choice depends on material viscosity and production scale, with Banbury favored for large batches and heavy-duty mixing, while two-roll mills suit finer, small-batch operations.

Advantages and Limitations of Banbury Mixing

Banbury mixing offers high shear and efficient dispersion, making it ideal for processing rubber, plastics, and composites with consistent quality. Its advantages include precise temperature control and faster cycle times, which enhance your productivity and product uniformity. Limitations involve higher initial equipment costs and increased maintenance complexity compared to two-roll mixing, which may impact operational budgets.

Pros and Cons of Two-Roll Mixing

Two-roll mixing offers precise control over temperature and shear force, making it ideal for processing sensitive polymers and achieving consistent compound quality. Its simpler design results in lower maintenance costs and easier cleaning compared to Banbury mixers, but it may have limitations in processing high-viscosity materials or large batch sizes. Your production efficiency benefits from faster batch turnover, although you might face challenges in scaling up complex formulations with this method.

Banbury mixing vs Two-roll mixing Infographic

libmatt.com

libmatt.com