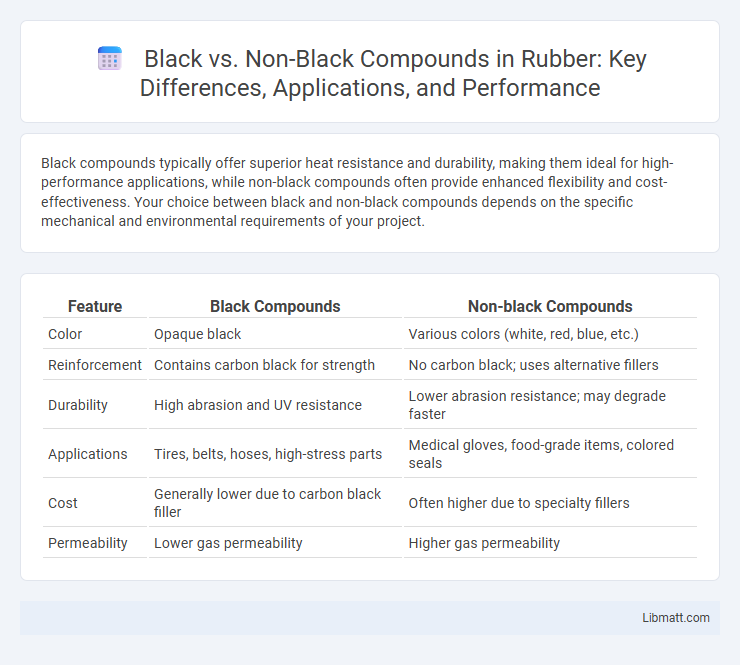

Black compounds typically offer superior heat resistance and durability, making them ideal for high-performance applications, while non-black compounds often provide enhanced flexibility and cost-effectiveness. Your choice between black and non-black compounds depends on the specific mechanical and environmental requirements of your project.

Table of Comparison

| Feature | Black Compounds | Non-black Compounds |

|---|---|---|

| Color | Opaque black | Various colors (white, red, blue, etc.) |

| Reinforcement | Contains carbon black for strength | No carbon black; uses alternative fillers |

| Durability | High abrasion and UV resistance | Lower abrasion resistance; may degrade faster |

| Applications | Tires, belts, hoses, high-stress parts | Medical gloves, food-grade items, colored seals |

| Cost | Generally lower due to carbon black filler | Often higher due to specialty fillers |

| Permeability | Lower gas permeability | Higher gas permeability |

Introduction to Black and Non-black Compounds

Black compounds primarily consist of carbon-rich materials such as carbon black, which enhance conductivity and durability in various industrial applications. Non-black compounds often include additives like pigments, fillers, and polymers that lack carbon black's distinctive coloration but provide specific mechanical or chemical properties. Differentiating these compounds is crucial for tailoring materials in sectors like rubber manufacturing, coatings, and plastics.

Defining Black Compounds

Black compounds refer to a class of chemical substances predominantly composed of carbon, often characterized by their black coloration due to high carbon content or complex molecular structures. These compounds exhibit unique properties such as high thermal stability and electrical conductivity, distinguishing them from non-black compounds that typically contain a broader variety of elements and exhibit different physical characteristics. Understanding the molecular configuration and elemental composition is essential in defining black compounds within materials science and industrial applications.

Key Characteristics of Non-black Compounds

Non-black compounds, also known as non-carbon black fillers, typically consist of materials such as silica, clay, and calcium carbonate, which enhance specific properties like abrasion resistance and tensile strength in rubber and plastic applications. These compounds often feature lower thermal conductivity and reduced hysteresis compared to black compounds, resulting in improved fuel efficiency and reduced heat build-up in tires. Your product formulation can benefit from the lighter color and enhanced processing capabilities provided by non-black compounds, making them ideal for applications requiring better aesthetics and lower rolling resistance.

Chemical Composition Differences

Black compounds typically contain a higher proportion of carbon black as a reinforcing filler, enhancing durability and UV resistance, whereas non-black compounds often use silica or other fillers to improve flexibility and reduce rolling resistance. The chemical composition of black compounds generally includes elemental carbon, sulfur for vulcanization, and synthetic rubber polymers like styrene-butadiene rubber (SBR). Your choice between black and non-black compounds can significantly impact performance characteristics due to these compositional differences.

Physical Properties Comparison

Black compounds exhibit higher electrical conductivity and thermal stability compared to non-black compounds due to their dense carbon structures and graphitic content. Non-black compounds generally have lower hardness and tensile strength, resulting in different mechanical behavior under stress. Your material selection should consider these physical property differences to optimize performance in specific applications.

Applications in Industry and Technology

Black compounds, primarily composed of carbon black, are extensively utilized in tire manufacturing for enhanced durability and abrasion resistance, while non-black compounds such as silica-based formulations are favored in automotive and aerospace industries for improved fuel efficiency and performance. Carbon black's high surface area and electrical conductivity make it essential in conductive polymers and battery electrodes, whereas non-black fillers like clay and calcium carbonate contribute to lightweight composites and advanced packaging materials. Emerging technologies leverage the unique properties of each compound type, optimizing applications in electronics, coatings, and high-performance elastomers.

Environmental Impact and Safety Considerations

Black compounds typically contain higher amounts of carbon black, enhancing durability and UV resistance, which reduces degradation and environmental microplastic release compared to non-black compounds. Non-black compounds, often using alternative fillers like silica, may offer improved recyclability and lower environmental toxicity, impacting lifecycle emissions positively. Safety considerations favor black compounds in applications requiring enhanced fire retardancy and heat resistance, while non-black compounds can reduce exposure to potentially harmful carbon black particulates during manufacturing.

Testing and Identification Methods

Testing and identification methods for black versus non-black compounds primarily rely on spectroscopic techniques such as Fourier-transform infrared spectroscopy (FTIR) and Raman spectroscopy, which analyze molecular vibrations to distinguish chemical structures. Elemental analysis and chromatography, including gas chromatography (GC) and high-performance liquid chromatography (HPLC), provide quantitative and qualitative data to differentiate complex mixtures based on specific compound compositions. Advanced methods involving mass spectrometry (MS) and nuclear magnetic resonance (NMR) spectroscopy further enhance the identification process by revealing molecular weights and detailed structural information critical for accurate classification.

Advantages and Limitations of Each Type

Black compounds, characterized by their high carbon black content, offer superior abrasion resistance and enhanced electrical conductivity, making them ideal for automotive and industrial applications. However, their high filler content can reduce flexibility and increase density, limiting use in lightweight or highly flexible products. Non-black compounds, often filled with silica or other non-carbon fillers, provide improved elasticity, lower rolling resistance, and enhanced wet traction, but they generally exhibit lower wear resistance and reduced conductivity compared to black compounds.

Future Trends in Compound Research

Future trends in Black vs Non-black compounds research highlight increasing interest in sustainable synthesis methods and enhanced material functionalities. Advanced characterization techniques, such as high-resolution spectroscopy and machine learning algorithms, are driving breakthroughs in understanding complex molecular interactions. Your engagement with emerging technologies will accelerate discovery and application of novel compounds with optimized properties for industrial and pharmaceutical use.

Black vs Non-black Compounds Infographic

libmatt.com

libmatt.com