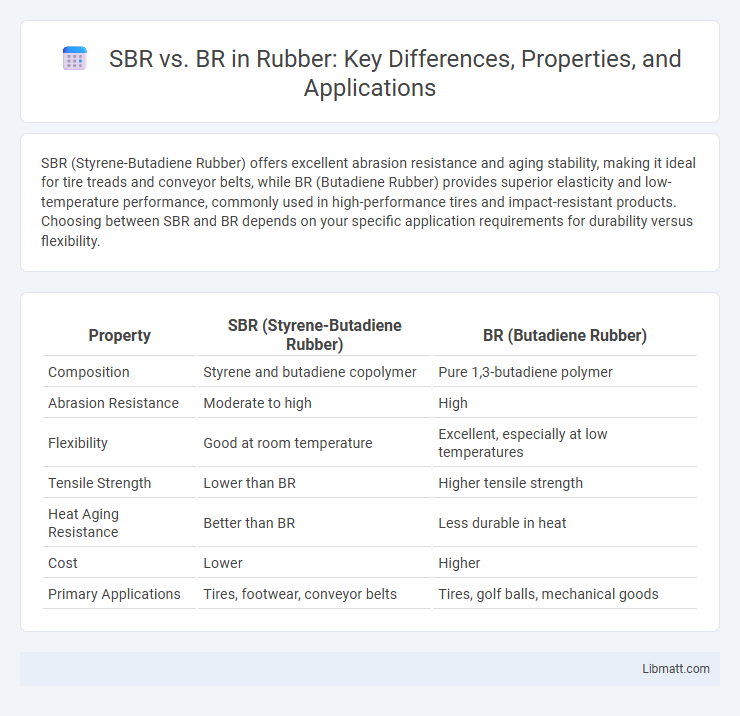

SBR (Styrene-Butadiene Rubber) offers excellent abrasion resistance and aging stability, making it ideal for tire treads and conveyor belts, while BR (Butadiene Rubber) provides superior elasticity and low-temperature performance, commonly used in high-performance tires and impact-resistant products. Choosing between SBR and BR depends on your specific application requirements for durability versus flexibility.

Table of Comparison

| Property | SBR (Styrene-Butadiene Rubber) | BR (Butadiene Rubber) |

|---|---|---|

| Composition | Styrene and butadiene copolymer | Pure 1,3-butadiene polymer |

| Abrasion Resistance | Moderate to high | High |

| Flexibility | Good at room temperature | Excellent, especially at low temperatures |

| Tensile Strength | Lower than BR | Higher tensile strength |

| Heat Aging Resistance | Better than BR | Less durable in heat |

| Cost | Lower | Higher |

| Primary Applications | Tires, footwear, conveyor belts | Tires, golf balls, mechanical goods |

Introduction to SBR and BR Rubber

Styrene-Butadiene Rubber (SBR) and Butadiene Rubber (BR) are two widely used synthetic rubbers in industrial applications. SBR, a copolymer of styrene and butadiene, offers excellent abrasion resistance and aging stability, making it ideal for tire treads and conveyor belts. BR, composed of butadiene monomers, provides superior elasticity and low-temperature flexibility, which enhances performance in high-speed tires and dynamic mechanical parts.

Chemical Composition and Structure

SBR (Styrene-Butadiene Rubber) is a synthetic copolymer combining styrene and butadiene monomers, resulting in a random or block copolymer structure that offers excellent abrasion resistance and aging stability. BR (Butadiene Rubber) consists solely of butadiene units, providing high elasticity, low glass transition temperature, and superior resilience due to its more uniform polymer chain structure. Your choice between SBR and BR should consider the desired balance between durability (SBR) and flexibility (BR) based on their distinct chemical compositions and structural properties.

Manufacturing Processes

Styrene-butadiene rubber (SBR) is produced primarily through emulsion polymerization, enabling controlled copolymer composition and better abrasion resistance, while butadiene rubber (BR) is mainly synthesized via solution polymerization, resulting in higher cis-1,4 content that offers superior elasticity and low-temperature performance. SBR's manufacturing process allows for enhanced aging resistance and adaptability for tire treads, whereas BR's process emphasizes molecular uniformity that improves resilience in high-performance applications. The choice between SBR and BR manufacturing impacts the polymer's molecular weight distribution, polymer chain microstructure, and ultimately the rubber's mechanical properties.

Physical and Mechanical Properties

Styrene-butadiene rubber (SBR) exhibits higher abrasion resistance and better aging stability compared to natural butadiene rubber (BR), making it suitable for applications requiring enhanced durability. BR offers superior tensile strength, flexibility, and low-temperature performance, which benefits products exposed to dynamic stress and cold environments. Both rubbers show excellent elasticity, but SBR's enhanced resilience and resistance to heat and oxidation distinguish it for automotive tires and industrial goods.

Performance in Industrial Applications

Styrene-Butadiene Rubber (SBR) offers superior abrasion resistance and aging stability compared to natural Butadiene Rubber (BR), making it more suitable for heavy-duty industrial applications such as conveyor belts and automotive tires. BR exhibits excellent low-temperature flexibility and resilience but typically underperforms SBR in wear resistance and heat aging, limiting its use in high-stress environments. Industrial sectors prioritize SBR for components exposed to continuous mechanical stress and elevated temperatures, leveraging its balanced performance characteristics to extend service life.

Cost Comparison: SBR vs BR

SBR (Styrene-Butadiene Rubber) generally offers a more cost-effective solution compared to BR (Butadiene Rubber) due to its lower raw material prices and widespread availability. While BR delivers superior abrasion resistance and elasticity, SBR's balance of performance and affordability often results in reduced overall production costs for manufacturers. You can optimize your budget by selecting SBR where cost efficiency takes precedence without significantly compromising quality.

Environmental Impact and Sustainability

SBR (Styrene-Butadiene Rubber) and BR (Butadiene Rubber) differ significantly in environmental impact and sustainability, with BR generally considered more eco-friendly due to its synthetic yet more biodegradable composition. The production of SBR involves styrene, a toxic monomer contributing to higher greenhouse gas emissions and environmental pollutants compared to BR. Sustainable alternatives in rubber manufacturing increasingly favor BR for reduced carbon footprint and improved recyclability in tire and industrial applications.

Advantages of Using SBR

SBR (Styrene-Butadiene Rubber) offers superior abrasion resistance and excellent aging stability compared to natural BR (Butadiene Rubber), making it ideal for tire treads and industrial applications. Enhanced wet grip and rolling resistance performance in SBR contribute to improved fuel efficiency and safety in automotive tires. Its cost-effectiveness and versatile processing capabilities provide significant manufacturing advantages over BR.

Advantages of Using BR

Butadiene Rubber (BR) offers enhanced abrasion resistance and better tensile strength compared to Styrene-Butadiene Rubber (SBR), making it ideal for high-performance tires and industrial applications. Its superior resilience and low-temperature flexibility improve durability and performance under extreme conditions. BR's lower hysteresis also contributes to improved fuel efficiency in automotive applications by reducing rolling resistance.

Choosing Between SBR and BR: Key Considerations

Choosing between SBR (Styrene-Butadiene Rubber) and BR (Butadiene Rubber) depends on factors such as abrasion resistance, elasticity, and temperature tolerance. SBR offers superior wear resistance and aging stability, making it ideal for tire treads and industrial applications, while BR excels in low-temperature flexibility and is preferred for high-performance tire sidewalls and mechanical components. Cost effectiveness and environmental exposure also influence the decision, with SBR providing better resistance to heat and chemicals compared to BR.

SBR vs BR Infographic

libmatt.com

libmatt.com