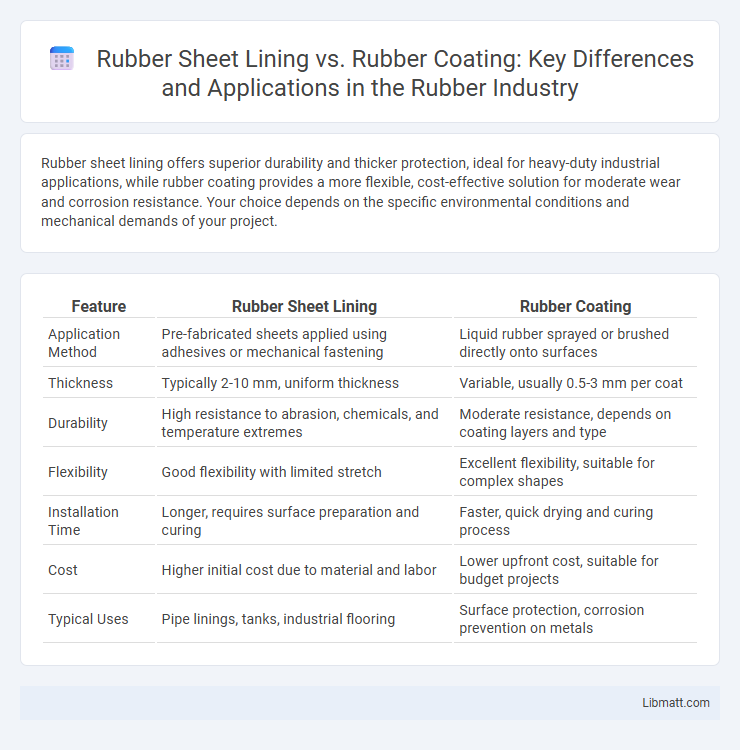

Rubber sheet lining offers superior durability and thicker protection, ideal for heavy-duty industrial applications, while rubber coating provides a more flexible, cost-effective solution for moderate wear and corrosion resistance. Your choice depends on the specific environmental conditions and mechanical demands of your project.

Table of Comparison

| Feature | Rubber Sheet Lining | Rubber Coating |

|---|---|---|

| Application Method | Pre-fabricated sheets applied using adhesives or mechanical fastening | Liquid rubber sprayed or brushed directly onto surfaces |

| Thickness | Typically 2-10 mm, uniform thickness | Variable, usually 0.5-3 mm per coat |

| Durability | High resistance to abrasion, chemicals, and temperature extremes | Moderate resistance, depends on coating layers and type |

| Flexibility | Good flexibility with limited stretch | Excellent flexibility, suitable for complex shapes |

| Installation Time | Longer, requires surface preparation and curing | Faster, quick drying and curing process |

| Cost | Higher initial cost due to material and labor | Lower upfront cost, suitable for budget projects |

| Typical Uses | Pipe linings, tanks, industrial flooring | Surface protection, corrosion prevention on metals |

Introduction to Rubber Sheet Lining and Rubber Coating

Rubber sheet lining involves applying pre-formed rubber sheets to surfaces for heavy-duty protection against abrasion, chemicals, and corrosion, commonly used in industrial tanks and pipes. Rubber coating is a liquid-applied method that forms a seamless, flexible rubberized layer, ideal for waterproofing and impact resistance on various substrates. Your choice between rubber sheet lining and rubber coating depends on the specific application requirements, durability needs, and surface conditions.

Definition and Overview of Rubber Sheet Lining

Rubber sheet lining involves applying pre-formed sheets of rubber to surfaces as a protective barrier against corrosion, abrasion, and chemical damage in industrial settings. Unlike rubber coating, which is a liquid-applied protective layer that cures in place, rubber sheet lining offers consistent thickness and enhanced durability for lining tanks, pipes, and vessels. Your choice between rubber sheet lining and rubber coating depends on factors like application environment, material compatibility, and maintenance requirements.

What is Rubber Coating?

Rubber coating is a protective layer applied to surfaces to enhance durability, corrosion resistance, and waterproofing, often used in industrial and marine environments. It forms a seamless, flexible barrier that protects against abrasion, chemicals, and weathering, extending the lifespan of equipment and structures. Your choice between rubber sheet lining and rubber coating depends on the level of protection needed and the specific application requirements.

Key Differences Between Rubber Sheet Lining and Rubber Coating

Rubber sheet lining involves installing pre-formed sheets to create a durable, uniform barrier, whereas rubber coating applies a liquid rubber compound directly to surfaces for flexible, seamless protection. Thickness, application methods, and repair processes differ significantly, with sheet lining offering easier replacement and coating providing superior adhesion to complex shapes. Understanding these distinctions helps you choose the optimal solution for abrasion resistance and chemical protection in industrial settings.

Material Composition and Types Used

Rubber sheet lining typically consists of thicker, vulcanized rubber sheets made from natural or synthetic rubber such as neoprene, EPDM, or nitrile, designed to provide durable protection against corrosion, abrasion, and chemical exposure. Rubber coating, on the other hand, involves applying a liquid rubber compound--often polyurethane or silicone-based--that cures to form a flexible, seamless protective layer, ideal for complex surfaces and detailed coverage. The sheet lining offers greater mechanical strength and thickness, while rubber coatings provide enhanced adhesion and conformability to irregular shapes.

Application Processes: Step-by-Step Comparison

Rubber sheet lining involves cutting pre-formed rubber sheets to size, placing them precisely on the substrate, and then vulcanizing or bonding them using adhesives or heat, ensuring a uniform protective layer ideal for pipelines and tanks. Rubber coating requires surface preparation, followed by the application of liquid rubber through spraying, brushing, or dipping in multiple layers, curing each layer to build a seamless protective barrier commonly used on metal structures and flooring. Both methods demand meticulous surface cleaning and curing times, but sheet lining offers thicker, more durable protection while coating provides flexibility and ease of application on complex geometries.

Performance and Durability Metrics

Rubber sheet lining offers superior abrasion resistance and thickness uniformity, resulting in enhanced durability for heavy-duty industrial applications. Rubber coating provides excellent chemical resistance and flexibility, making it ideal for surfaces requiring corrosion protection and impact absorption. Performance metrics reveal that sheet lining typically withstands higher mechanical stresses, while rubber coating excels in adhesion and weather resistance.

Typical Industrial and Commercial Uses

Rubber sheet lining is extensively used in industrial applications requiring corrosion and abrasion resistance, such as chemical processing tanks, slurry pipelines, and water treatment facilities. Rubber coating is commonly applied to surfaces like pipelines, storage tanks, and metal structures to provide protection against corrosion, weathering, and impact damage in commercial and industrial environments. Both solutions enhance equipment longevity but are selected based on the specific need for flexibility, thickness, and resistance to chemicals or physical wear.

Cost Analysis and Maintenance Considerations

Rubber sheet lining typically involves higher initial costs due to material thickness and installation complexity but offers superior durability and resistance to abrasion, reducing long-term maintenance expenses. Rubber coating is more cost-effective upfront and easier to apply for irregular surfaces but may require more frequent reapplication and repair to maintain effectiveness. Your choice depends on balancing upfront investment and ongoing maintenance to achieve optimal cost-efficiency.

Choosing the Right Solution: Factors to Consider

Selecting between rubber sheet lining and rubber coating depends on factors such as application environment, exposure to chemicals, and required durability. Rubber sheet linings offer superior thickness and impact resistance for heavy-duty industrial use, while rubber coatings provide seamless protection ideal for complex surfaces and easier maintenance. Cost, installation time, and repair frequency also influence the choice, with sheet linings generally requiring more labor but offering longer service life.

Rubber Sheet Lining vs Rubber Coating Infographic

libmatt.com

libmatt.com