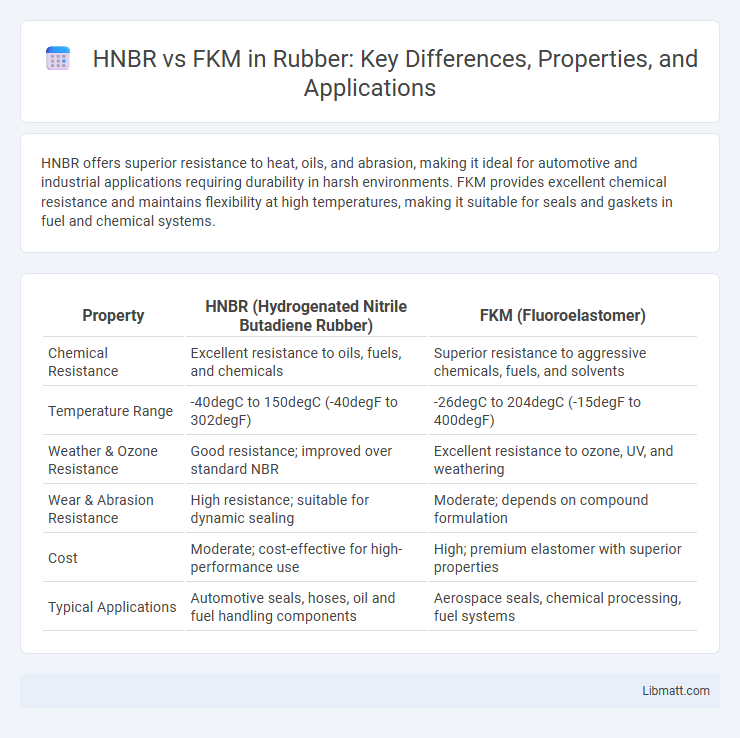

HNBR offers superior resistance to heat, oils, and abrasion, making it ideal for automotive and industrial applications requiring durability in harsh environments. FKM provides excellent chemical resistance and maintains flexibility at high temperatures, making it suitable for seals and gaskets in fuel and chemical systems.

Table of Comparison

| Property | HNBR (Hydrogenated Nitrile Butadiene Rubber) | FKM (Fluoroelastomer) |

|---|---|---|

| Chemical Resistance | Excellent resistance to oils, fuels, and chemicals | Superior resistance to aggressive chemicals, fuels, and solvents |

| Temperature Range | -40degC to 150degC (-40degF to 302degF) | -26degC to 204degC (-15degF to 400degF) |

| Weather & Ozone Resistance | Good resistance; improved over standard NBR | Excellent resistance to ozone, UV, and weathering |

| Wear & Abrasion Resistance | High resistance; suitable for dynamic sealing | Moderate; depends on compound formulation |

| Cost | Moderate; cost-effective for high-performance use | High; premium elastomer with superior properties |

| Typical Applications | Automotive seals, hoses, oil and fuel handling components | Aerospace seals, chemical processing, fuel systems |

Introduction to HNBR and FKM

HNBR (Hydrogenated Nitrile Butadiene Rubber) is a synthetic elastomer known for its excellent resistance to heat, oil, and chemicals, making it ideal for harsh industrial environments. FKM (Fluoroelastomer) offers superior chemical and temperature resistance, particularly against fuels, lubricants, and aggressive fluids, often used in automotive and aerospace applications. Your choice between HNBR and FKM depends on specific performance needs, such as temperature range and chemical compatibility.

Chemical Structure and Composition

HNBR (Hydrogenated Nitrile Butadiene Rubber) features a saturated hydrocarbon backbone due to hydrogenation of the nitrile butadiene rubber, enhancing its chemical stability and resistance to oxidation. FKM (Fluoroelastomer) contains a fully fluorinated polymer chain, providing exceptional heat and chemical resistance, especially against fuels and solvents. Your choice between HNBR and FKM depends on the specific chemical exposure and temperature requirements of your application.

Key Physical Properties Comparison

HNBR (Hydrogenated Nitrile Butadiene Rubber) exhibits superior tensile strength and abrasion resistance compared to FKM (Fluoroelastomer), making it ideal for demanding mechanical applications. FKM offers higher chemical resistance and excellent temperature stability, withstanding temperatures up to 250degC, whereas HNBR typically performs well up to 150degC. Both materials provide good oil and fuel resistance, but HNBR's enhanced durability suits dynamic sealing, while FKM excels in extreme chemical environments.

Temperature Resistance: HNBR vs FKM

HNBR (Hydrogenated Nitrile Butadiene Rubber) exhibits excellent temperature resistance, typically withstanding continuous use from -40degC up to 150degC, and short-term exposure up to 170degC. FKM (Fluoroelastomer), known for its superior heat resistance, performs reliably in continuous temperatures ranging from -26degC to 205degC, with some grades tolerating peaks up to 230degC. The higher temperature tolerance of FKM makes it suitable for extreme high-temperature applications, while HNBR offers a balance of thermal stability and chemical resistance for moderate temperature environments.

Chemical Compatibility and Resistance

HNBR (Hydrogenated Nitrile Butadiene Rubber) exhibits superior chemical compatibility with oils, fuels, and alkalis, making it highly resistant to abrasion, heat, and ozone, which makes it ideal for automotive and industrial applications. FKM (Fluoroelastomer), known for exceptional resistance to a wide range of chemicals including acids, solvents, and fuels, offers excellent performance in harsh chemical environments and high-temperature conditions. Both elastomers provide robust chemical resistance, but HNBR is preferred for applications involving hydrocarbons and mechanical stress, while FKM excels in aggressive chemical exposure and extreme temperatures.

Mechanical Performance and Durability

HNBR (Hydrogenated Nitrile Butadiene Rubber) exhibits superior mechanical performance with higher tensile strength and excellent abrasion resistance compared to FKM (Fluoroelastomer), making it ideal for demanding applications requiring robust wear durability. HNBR maintains mechanical properties at elevated temperatures up to 150degC, while FKM offers better chemical resistance but slightly lower mechanical tensile strength and elongation at break. Both materials excel in harsh environments, but HNBR outperforms FKM in dynamic stress and mechanical fatigue resistance, ensuring prolonged durability.

Typical Applications and Industry Use

HNBR excels in automotive and oil & gas industries due to its superior resistance to heat, oils, and chemicals, making it ideal for seals, gaskets, and O-rings in harsh environments. FKM (fluoroelastomers) dominates aerospace, chemical processing, and electronics sectors with exceptional chemical resistance and high-temperature stability, suitable for fuel system components, hoses, and valve seals. Choosing between HNBR and FKM depends on specific exposure conditions, with HNBR preferred for dynamic sealing in aggressive fluids and FKM favored for extreme chemical and thermal environments.

Cost Considerations: HNBR vs FKM

HNBR (Hydrogenated Nitrile Butadiene Rubber) generally offers a more cost-effective solution compared to FKM (Fluoroelastomer), with lower raw material and production expenses making it suitable for budget-conscious applications. FKM provides superior chemical resistance and higher temperature tolerance, but these advantages come with higher costs in both material and processing. Choosing between HNBR and FKM hinges on balancing performance requirements with cost constraints, as HNBR tends to reduce overall expenditure while FKM justifies its premium pricing through enhanced durability and longevity in extreme conditions.

Advantages and Limitations of Each Material

HNBR excels in high-temperature resistance up to 150degC, superior abrasion resistance, and excellent chemical stability against oils and fuels, making it ideal for automotive and industrial sealing applications. FKM offers outstanding resistance to extreme temperatures above 200degC, exceptional chemical inertness against aggressive solvents and acids, and excellent compression set resistance, suitable for aerospace and chemical processing industries. Limitations of HNBR include reduced performance in extreme chemical environments and lower heat resistance compared to FKM, while FKM is generally more expensive and has limited compatibility with ketones and certain steam exposures.

How to Choose: HNBR or FKM for Your Application

Selecting between HNBR and FKM depends on your application's temperature range, chemical exposure, and mechanical stress requirements. HNBR excels in resisting abrasion, heat up to 150degC, and certain oils, making it ideal for automotive and industrial sealing where durability is critical. FKM offers superior chemical resistance and temperature tolerance up to 200degC, best suited for harsh chemical environments and high-temperature applications.

HNBR vs FKM Infographic

libmatt.com

libmatt.com