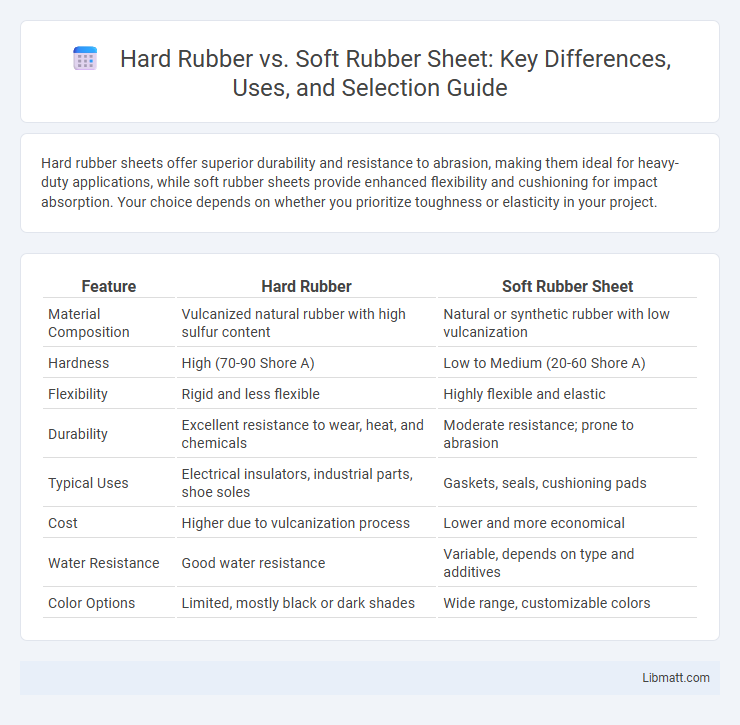

Hard rubber sheets offer superior durability and resistance to abrasion, making them ideal for heavy-duty applications, while soft rubber sheets provide enhanced flexibility and cushioning for impact absorption. Your choice depends on whether you prioritize toughness or elasticity in your project.

Table of Comparison

| Feature | Hard Rubber | Soft Rubber Sheet |

|---|---|---|

| Material Composition | Vulcanized natural rubber with high sulfur content | Natural or synthetic rubber with low vulcanization |

| Hardness | High (70-90 Shore A) | Low to Medium (20-60 Shore A) |

| Flexibility | Rigid and less flexible | Highly flexible and elastic |

| Durability | Excellent resistance to wear, heat, and chemicals | Moderate resistance; prone to abrasion |

| Typical Uses | Electrical insulators, industrial parts, shoe soles | Gaskets, seals, cushioning pads |

| Cost | Higher due to vulcanization process | Lower and more economical |

| Water Resistance | Good water resistance | Variable, depends on type and additives |

| Color Options | Limited, mostly black or dark shades | Wide range, customizable colors |

Introduction to Hard and Soft Rubber Sheets

Hard rubber sheets are composed of vulcanized natural rubber, offering high durability, chemical resistance, and excellent electrical insulation properties suitable for industrial applications. Soft rubber sheets, made from materials like silicone or neoprene, provide flexibility, cushioning, and superior weather resistance, making them ideal for sealing, gasketing, and vibration dampening. Understanding the distinct physical properties and common uses of hard versus soft rubber sheets aids in selecting the appropriate material for specific engineering and manufacturing needs.

Key Material Differences

Hard rubber sheets exhibit high-density composition and increased rigidity, offering superior durability and resistance to abrasion, heat, and chemicals. Soft rubber sheets provide greater flexibility, elasticity, and cushioning due to their lower density and softer polymer blends, making them ideal for applications requiring sealing, vibration damping, or impact absorption. Understanding these key material differences helps you select the appropriate rubber type based on hardness, flexibility, and environmental resistance requirements.

Durability and Wear Resistance

Hard rubber sheets exhibit superior durability and wear resistance due to their dense molecular structure, making them ideal for heavy-duty applications requiring long-lasting performance. Soft rubber sheets, while more flexible and impact-absorbing, tend to wear out faster under abrasive conditions and high friction environments. Choosing between hard and soft rubber sheets depends on the specific need for toughness versus flexibility in the intended use.

Flexibility and Elasticity Comparison

Hard rubber sheets offer lower flexibility and elasticity, making them more rigid and durable for structural applications. Soft rubber sheets provide superior flexibility and higher elasticity, allowing for better shock absorption and adaptability to complex surfaces. Your choice depends on whether you need a material that bends easily or one that maintains shape under pressure.

Common Industrial Applications

Hard rubber sheets are widely used in industrial applications requiring high durability and resistance to abrasion, such as conveyor belts, gaskets, and electrical insulation components. Soft rubber sheets excel in providing flexibility and cushioning, making them ideal for sealing, vibration damping, and protective padding in machinery. Choosing between hard and soft rubber sheets depends on Your specific needs for wear resistance, flexibility, and impact absorption in manufacturing processes.

Chemical Resistance of Each Type

Hard rubber sheets exhibit superior chemical resistance against acids, alkalis, and solvents, making them ideal for harsh industrial environments where durability is critical. Soft rubber sheets offer moderate chemical resistance, suitable for applications requiring flexibility but may degrade faster when exposed to aggressive chemicals. Your choice should depend on the specific chemical exposure and durability requirements of your project.

Performance in Extreme Temperatures

Hard rubber sheets maintain structural integrity and resist deformation at high temperatures up to 150degC, making them suitable for industrial applications requiring heat resistance. Soft rubber sheets excel in flexibility and shock absorption, performing well in low temperatures down to -40degC without cracking or losing elasticity. Selection between hard and soft rubber sheets depends on the specific temperature range and mechanical demands of the application environment.

Cost Considerations and Longevity

Hard rubber sheets typically offer greater longevity due to their increased density and resistance to wear, making them cost-effective for long-term applications despite a higher upfront price. Soft rubber sheets are generally less expensive initially but may require more frequent replacement, increasing overall maintenance costs over time. Selecting the right type depends on your budget constraints and the expected durability needed for the specific application.

Selection Tips for Specific Uses

Choose hard rubber sheets for applications requiring high durability, chemical resistance, and impact strength, such as gaskets and industrial machinery. Soft rubber sheets excel in cushioning, flexibility, and noise reduction, making them ideal for seals, vibration dampening, and protective padding. Consider the working environment, temperature range, and mechanical stress to select the appropriate rubber hardness for optimal performance.

Summary: Choosing the Right Rubber Sheet

Hard rubber sheets offer superior durability, chemical resistance, and structural support, making them ideal for heavy-duty applications such as gaskets, insulation, and industrial machinery. Soft rubber sheets provide enhanced flexibility, cushioning, and impact absorption, suitable for sealing, vibration dampening, and protective surfaces. Selecting the right rubber sheet depends on specific requirements like hardness, elasticity, environmental exposure, and mechanical stress to ensure optimal performance and longevity.

Hard Rubber vs Soft Rubber Sheet Infographic

libmatt.com

libmatt.com