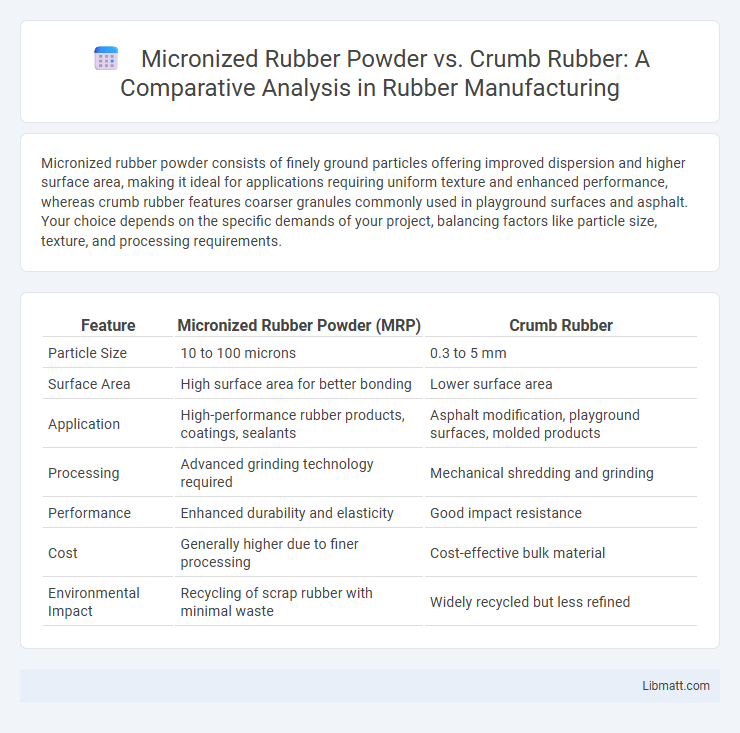

Micronized rubber powder consists of finely ground particles offering improved dispersion and higher surface area, making it ideal for applications requiring uniform texture and enhanced performance, whereas crumb rubber features coarser granules commonly used in playground surfaces and asphalt. Your choice depends on the specific demands of your project, balancing factors like particle size, texture, and processing requirements.

Table of Comparison

| Feature | Micronized Rubber Powder (MRP) | Crumb Rubber |

|---|---|---|

| Particle Size | 10 to 100 microns | 0.3 to 5 mm |

| Surface Area | High surface area for better bonding | Lower surface area |

| Application | High-performance rubber products, coatings, sealants | Asphalt modification, playground surfaces, molded products |

| Processing | Advanced grinding technology required | Mechanical shredding and grinding |

| Performance | Enhanced durability and elasticity | Good impact resistance |

| Cost | Generally higher due to finer processing | Cost-effective bulk material |

| Environmental Impact | Recycling of scrap rubber with minimal waste | Widely recycled but less refined |

Introduction to Micronized Rubber Powder and Crumb Rubber

Micronized Rubber Powder (MRP) consists of finely ground rubber particles typically less than 150 microns, offering enhanced surface area and uniformity for superior dispersion in various applications. Crumb Rubber is made from larger rubber granules, usually ranging from 1 mm to 4 mm, commonly used in playground surfaces, asphalt modification, and molded rubber products. Both materials originate from recycled tires but differ significantly in particle size, processing methods, and performance characteristics.

Manufacturing Processes: Micronized Rubber Powder vs Crumb Rubber

Micronized Rubber Powder (MRP) is produced through advanced cryogenic grinding that results in ultra-fine particles typically less than 200 microns, enhancing dispersion and performance in various applications. Crumb Rubber is manufactured by ambient grinding or cryogenic methods but yields coarser particles ranging from 0.5 to 4 millimeters, commonly used in asphalt and playground surfaces. Understanding these manufacturing distinctions helps You select the right rubber material for improved product quality and processing efficiency.

Particle Size and Surface Area Differences

Micronized rubber powder (MRP) features significantly finer particle sizes, typically less than 200 microns, compared to crumb rubber, which ranges from 1000 to 4000 microns, resulting in a much larger surface area per unit weight. This increased surface area of MRP enhances its reactivity and compatibility when used in applications like asphalt modification or rubber compounding. Understanding these differences in particle size and surface area helps optimize your material selection for improved performance and durability.

Material Purity and Contaminant Levels

Micronized Rubber Powder (MRP) offers superior material purity compared to Crumb Rubber, as it undergoes finer grinding and advanced screening processes that significantly reduce contaminants like fiber, metal, and dust. This enhanced purity ensures better performance and consistency in applications, making MRP ideal for precision-demanding industries such as automotive and construction. Your choice of rubber material influences product quality, and opting for MRP minimizes impurity-related issues commonly associated with Crumb Rubber.

Performance in Rubber Products

Micronized Rubber Powder (MRP) offers superior dispersion and increased surface area compared to Crumb Rubber, resulting in improved mechanical properties and enhanced durability in rubber products. Your formulations benefit from MRP's fine particle size, which enables better interaction with polymer matrices, leading to increased tensile strength, elasticity, and abrasion resistance. Crumb Rubber, with its larger particle size, typically provides lower performance in terms of uniformity and long-term stability in rubber applications.

Environmental Impact and Sustainability

Micronized Rubber Powder (MRP) offers enhanced sustainability compared to Crumb Rubber due to its finer particle size, enabling more efficient recycling and reduced waste volume in various applications like asphalt and molded products. The production process of MRP typically consumes less energy and results in lower emissions than the larger, less processed Crumb Rubber. Both materials promote rubber waste diversion from landfills, but MRP's improved compatibility with polymers extends product lifespan, boosting environmental benefits in circular economy practices.

Cost Comparison and Market Availability

Micronized rubber powder generally costs more than crumb rubber due to its finer particle size and increased processing requirements, which enhance performance in applications like asphalt and rubber compounds. Crumb rubber is widely available and more cost-effective for bulk uses such as playground surfaces and road materials, making it a popular choice in large-scale projects. Your decision between the two should balance budget constraints with the desired material properties and local market availability.

Applications in Industry: MRP vs Crumb Rubber

Micronized Rubber Powder (MRP) and Crumb Rubber serve distinct roles in industry, with MRP favored for precision applications like asphalt modification, plastics, and coatings due to its fine particle size and uniform consistency. Crumb Rubber is predominantly used in robust applications such as playground surfaces, road pavements, and rubber mats, benefiting from its larger particle size and cost-effectiveness. Your choice between MRP and Crumb Rubber should consider the specific performance requirements and desired material properties of your application.

Regulatory Standards and Compliance

Micronized Rubber Powder (MRP) meets stringent regulatory standards due to its fine particle size and enhanced purity, which reduces contaminants and improves safety compliance in applications such as tire manufacturing and coatings. Crumb Rubber, being coarser and less processed, faces stricter scrutiny under environmental regulations related to heavy metals and organic compounds, impacting its usability in consumer products. To ensure your project adheres to evolving environmental and safety regulations, selecting MRP can simplify compliance and minimize regulatory risks.

Future Trends in Rubber Recycling Technologies

Micronized Rubber Powder (MRP) offers enhanced dispersion and improved performance compared to traditional crumb rubber, supporting the shift towards more sustainable and efficient rubber recycling. Emerging technologies focus on refining particle size and surface treatment of MRP to increase its compatibility in various applications, driving innovation in tire manufacturing and asphalt modification. Your investment in MRP-based solutions aligns with the future trend of high-value, eco-friendly rubber materials that reduce environmental impact and promote circular economy principles.

Micronized Rubber Powder vs Crumb Rubber Infographic

libmatt.com

libmatt.com