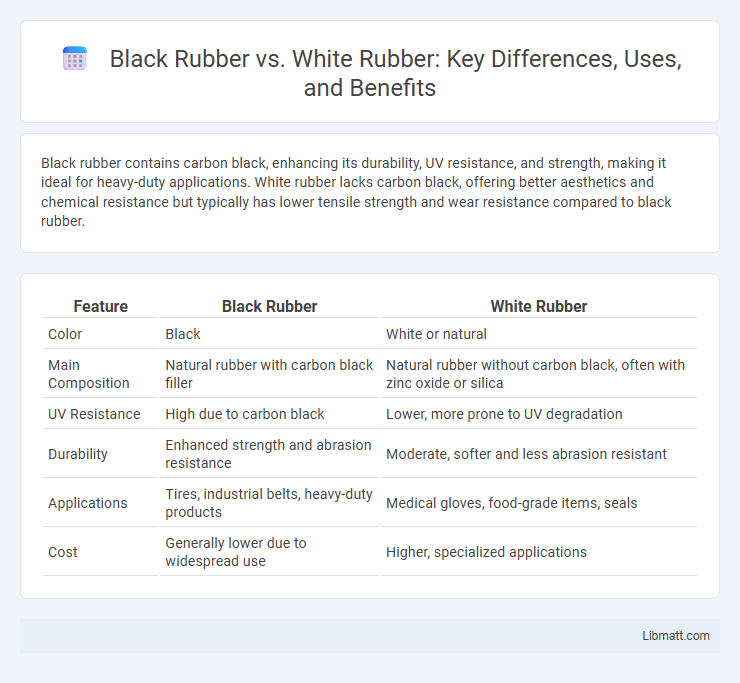

Black rubber contains carbon black, enhancing its durability, UV resistance, and strength, making it ideal for heavy-duty applications. White rubber lacks carbon black, offering better aesthetics and chemical resistance but typically has lower tensile strength and wear resistance compared to black rubber.

Table of Comparison

| Feature | Black Rubber | White Rubber |

|---|---|---|

| Color | Black | White or natural |

| Main Composition | Natural rubber with carbon black filler | Natural rubber without carbon black, often with zinc oxide or silica |

| UV Resistance | High due to carbon black | Lower, more prone to UV degradation |

| Durability | Enhanced strength and abrasion resistance | Moderate, softer and less abrasion resistant |

| Applications | Tires, industrial belts, heavy-duty products | Medical gloves, food-grade items, seals |

| Cost | Generally lower due to widespread use | Higher, specialized applications |

Introduction to Black Rubber vs White Rubber

Black rubber, commonly made from natural rubber combined with carbon black, offers superior durability and resistance to abrasion and UV exposure, making it ideal for heavy-duty applications. White rubber, often produced without carbon black and utilizing alternative fillers, is preferred in environments requiring low contamination and high purity, such as food processing or medical industries. Understanding these material differences helps you select the appropriate rubber type for your specific performance and safety requirements.

Composition and Material Differences

Black rubber typically contains carbon black as a reinforcing filler, which enhances durability, UV resistance, and tensile strength, making it ideal for heavy-duty applications. White rubber, or natural rubber without carbon black, often uses silica or other fillers, resulting in lower abrasion resistance but improved flexibility and lighter color for aesthetic or specialized uses. The distinct compositions influence their mechanical properties, with black rubber offering superior wear resistance and white rubber providing better chemical resistance and softness.

Manufacturing Process Comparison

Black rubber is typically produced using carbon black as a reinforcing filler, enhancing durability and UV resistance through a vulcanization process involving sulfur and heat. White rubber, often made with silica or titanium dioxide fillers, undergoes a similar vulcanization but requires careful control to maintain its color and avoid contamination. Understanding these differences in the manufacturing process helps you select the right rubber type based on performance requirements and aesthetic preferences.

Durability and Performance Factors

Black rubber contains carbon black, which significantly enhances its durability and resistance to wear, making it ideal for heavy-duty applications. White rubber, often made from silica or other non-carbon fillers, provides better grip and flexibility but tends to wear down faster under extreme conditions. Understanding these performance factors helps you choose the right material based on your specific durability and functionality needs.

Applications and Industry Use Cases

Black rubber, reinforced with carbon black, offers superior durability and UV resistance, making it ideal for automotive tires, industrial belts, and heavy-duty hoses used in construction and manufacturing industries. White rubber, often made without carbon black fillers, is preferred in medical, food processing, and pharmaceutical sectors due to its non-staining properties and chemical inertness. Both types serve specialized purposes, with black rubber dominating high-wear applications and white rubber excelling where purity and cleanliness are critical.

Aesthetic and Design Considerations

Black rubber offers a sleek, modern aesthetic commonly used in products requiring a minimalist or industrial design look, while white rubber provides a clean, bright appearance that enhances visibility and a sense of purity in design. White rubber's susceptibility to discoloration over time may influence its selection for applications where long-term appearance is critical, unlike black rubber, which tends to maintain its color integrity and mask dirt. Designers often choose black rubber for durability and subtlety in tone, whereas white rubber suits environments prioritizing contrast and a fresh, hygienic visual impact.

Maintenance and Cleaning Challenges

Black rubber resists stains and dirt better than white rubber, reducing the frequency of cleaning required, while white rubber shows dirt, dust, and discoloration more visibly, demanding more frequent and thorough maintenance. Cleaning black rubber typically involves mild soap and water to maintain its appearance without fading, whereas white rubber requires specialized cleaners and often scrubbing to remove tough stains and yellowing. Both materials can degrade if exposed to harsh chemicals or improper cleaning methods, emphasizing the need for tailored maintenance routines to preserve their durability.

Environmental Impact and Sustainability

Black rubber typically contains carbon black, which improves durability and UV resistance but raises environmental concerns due to the energy-intensive production and potential pollution. White rubber often uses alternative fillers like silica, which offer better recyclability and lower environmental impact, contributing to greater sustainability. Choosing white rubber can reduce carbon footprint and support eco-friendly manufacturing practices in the rubber industry.

Cost and Economic Implications

Black rubber, commonly made with carbon black as a reinforcing filler, generally offers lower production costs and greater durability, making it economically advantageous for mass manufacturing in automotive and industrial applications. White rubber, often silica-filled or composed of natural rubber without carbon black, requires more expensive processing and raw materials, leading to higher prices and limited large-scale use, primarily in specialized products like white soles or medical gloves. The cost differential impacts supply chain decisions, with black rubber favored for bulk production due to its lower price point and higher wear resistance, while white rubber targets premium markets despite its greater expense.

Choosing the Right Rubber for Your Needs

Black rubber offers superior durability and resistance to abrasion, making it ideal for heavy-duty industrial applications and heavy foot traffic areas. White rubber provides better chemical resistance and is commonly used in medical or food processing environments where cleanliness and non-contamination are crucial. Selecting the right rubber depends on the specific environment, required durability, and exposure to chemicals or wear factors.

Black Rubber vs White Rubber Infographic

libmatt.com

libmatt.com