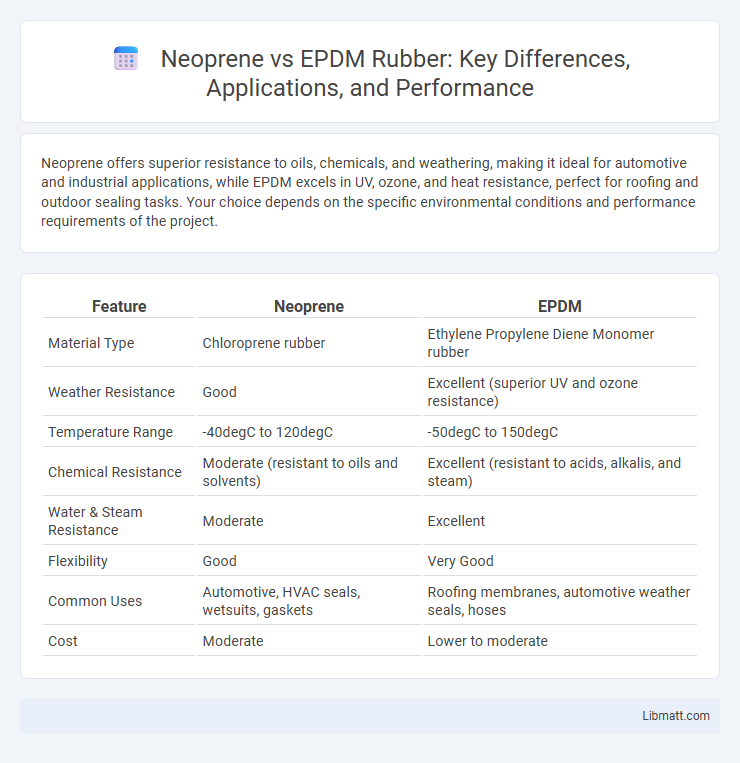

Neoprene offers superior resistance to oils, chemicals, and weathering, making it ideal for automotive and industrial applications, while EPDM excels in UV, ozone, and heat resistance, perfect for roofing and outdoor sealing tasks. Your choice depends on the specific environmental conditions and performance requirements of the project.

Table of Comparison

| Feature | Neoprene | EPDM |

|---|---|---|

| Material Type | Chloroprene rubber | Ethylene Propylene Diene Monomer rubber |

| Weather Resistance | Good | Excellent (superior UV and ozone resistance) |

| Temperature Range | -40degC to 120degC | -50degC to 150degC |

| Chemical Resistance | Moderate (resistant to oils and solvents) | Excellent (resistant to acids, alkalis, and steam) |

| Water & Steam Resistance | Moderate | Excellent |

| Flexibility | Good | Very Good |

| Common Uses | Automotive, HVAC seals, wetsuits, gaskets | Roofing membranes, automotive weather seals, hoses |

| Cost | Moderate | Lower to moderate |

Introduction to Neoprene and EPDM

Neoprene and EPDM are two popular synthetic rubber materials known for their durability and versatility in industrial applications. Neoprene excels in resistance to oils, chemicals, and weathering, making it ideal for automotive and marine uses. EPDM offers superior heat, ozone, and weather resistance, which makes it a preferred choice for roofing, seals, and outdoor equipment, ensuring your projects withstand harsh environmental conditions.

Chemical Composition and Structure

Neoprene is a synthetic rubber composed of polychloroprene, featuring chlorine atoms that provide inherent flame resistance and oil stability. EPDM consists of ethylene, propylene, and a diene comonomer, resulting in a saturated polymer backbone with excellent resistance to heat, ozone, and weathering. The structural differences between chlorinated Neoprene and hydrocarbon-based EPDM significantly influence their chemical resistance and mechanical properties.

Key Properties of Neoprene

Neoprene exhibits excellent resistance to oils, chemicals, and weathering, making it ideal for automotive and industrial applications. Its high tensile strength and flexibility ensure durability under varying temperatures and mechanical stress. You benefit from its superior insulation and cushioning properties in seals, gaskets, and protective gear.

Key Properties of EPDM

EPDM (ethylene propylene diene monomer) rubber is renowned for its exceptional resistance to weathering, ozone, UV rays, and extreme temperatures, making it ideal for outdoor applications. Its outstanding electrical insulation properties and excellent resistance to water, steam, and a wide range of chemicals contribute to its versatility in automotive seals, roofing membranes, and industrial gasketing. EPDM's superior elasticity and durability under thermal stress distinguish it from neoprene, which offers better oil and solvent resistance but less environmental resilience.

Temperature Resistance Comparison

Neoprene offers excellent temperature resistance, typically withstanding conditions from -40degF to 250degF, making it suitable for applications involving moderate heat exposure. EPDM outperforms neoprene in high-temperature environments, withstanding continuous exposure up to 300degF and short bursts up to 350degF, which makes it ideal for steam and hot water applications. Your choice between neoprene and EPDM should consider the specific temperature range required for optimal material performance and longevity.

Weather and UV Resistance

Neoprene exhibits excellent weather and UV resistance, making it suitable for outdoor applications exposed to harsh sunlight, ozone, and varying temperatures. EPDM outperforms Neoprene in resisting long-term UV degradation and extreme weather conditions, showing superior elasticity and durability in prolonged sun exposure and ozone-rich environments. Both elastomers offer robust protection, but EPDM is generally preferred for continuous outdoor use due to its enhanced resistance to UV and weathering effects.

Chemical and Oil Resistance

Neoprene exhibits superior resistance to hydrocarbons, oils, and some chemicals, making it ideal for automotive and industrial applications where exposure to petroleum-based substances is frequent. EPDM offers excellent resistance to polar chemicals, ozone, and weathering but performs poorly against oils and fuels, limiting its use in environments with petroleum exposure. Selecting between Neoprene and EPDM depends on the chemical composition of the substances involved and the specific resistance requirements of the application.

Common Applications of Neoprene

Neoprene is widely used in applications requiring excellent resistance to oil, chemicals, and weathering, making it ideal for gaskets, seals, and automotive hoses. Its flexibility and durability also make it popular in wetsuits, orthopedic braces, and industrial grommets. If you're seeking reliable material performance in harsh environments, neoprene offers versatile solutions tailored to your needs.

Common Applications of EPDM

EPDM is widely used in roofing membranes, automotive weather-stripping, and electrical insulation due to its excellent resistance to heat, ozone, and ultraviolet rays. Its superior durability in outdoor environments makes it ideal for seals, gaskets, and hoses exposed to harsh weather conditions. You will find EPDM frequently applied in greenhouse panels, pond liners, and window seals to ensure long-lasting performance.

Choosing the Right Material for Your Needs

Neoprene offers excellent resistance to oils, chemicals, and weathering, making it ideal for automotive and industrial applications requiring durability in harsh environments. EPDM excels in resisting heat, ozone, and aging, which suits outdoor uses, roofing, and HVAC systems exposed to sunlight and extreme weather. Understanding your specific environmental conditions and exposure factors ensures you choose the right material to maximize performance and lifespan.

Neoprene vs EPDM Infographic

libmatt.com

libmatt.com